- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

KS-PVC Foam Board

-

Thickness:

-

12mm 15mm 18mm 20mm

-

Size:

-

1.22m*2.44m or Customization

-

Product name:

-

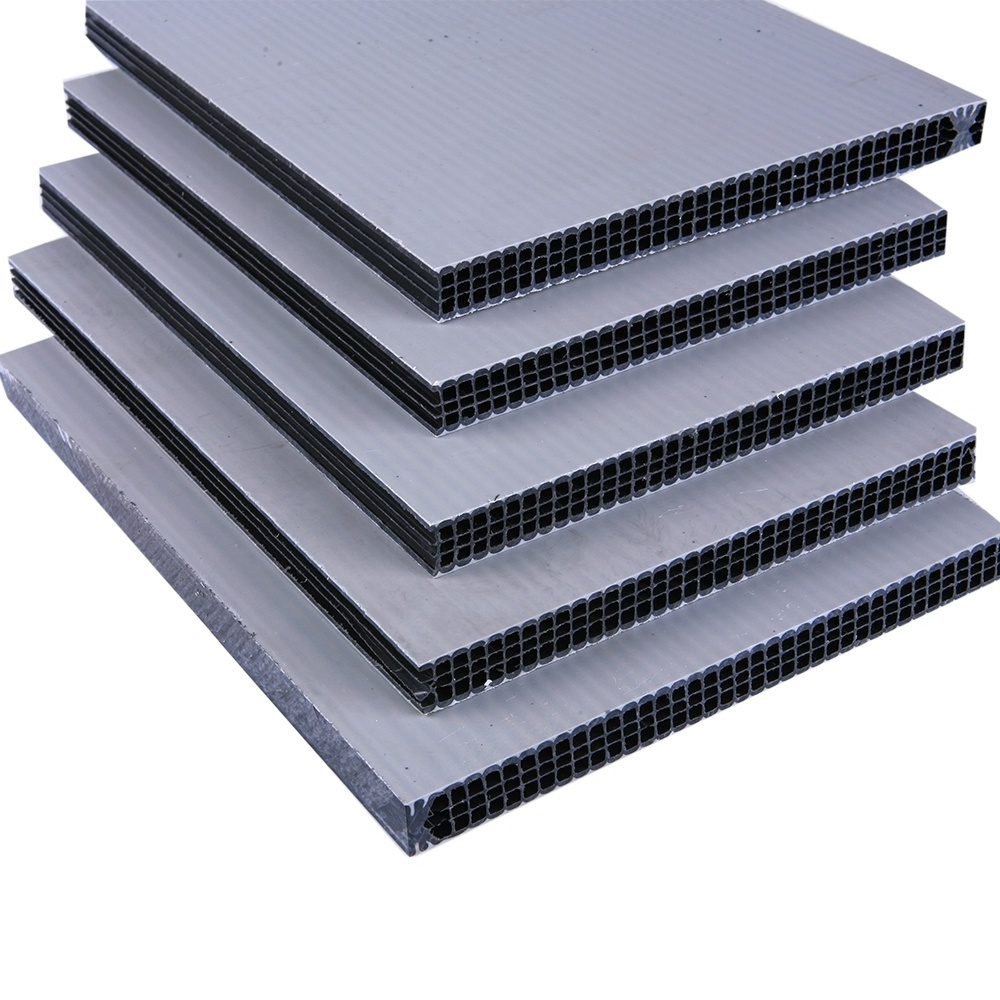

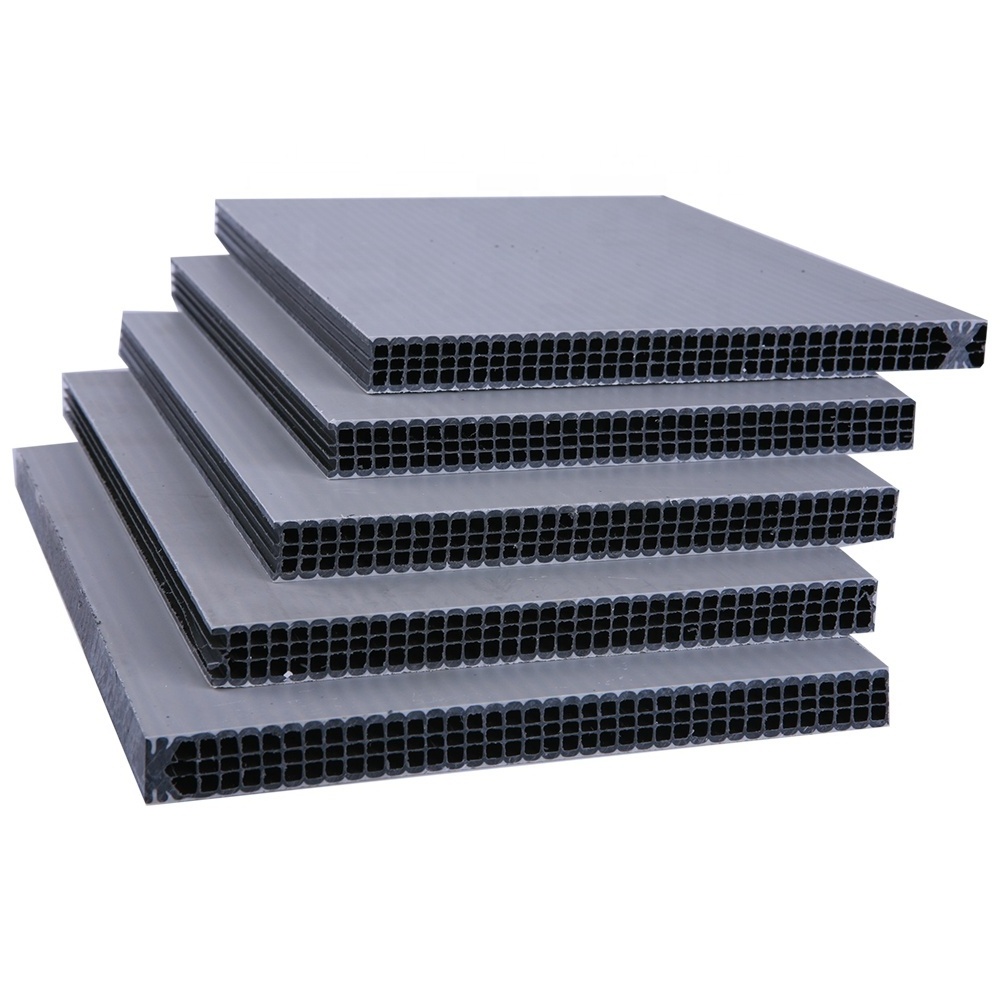

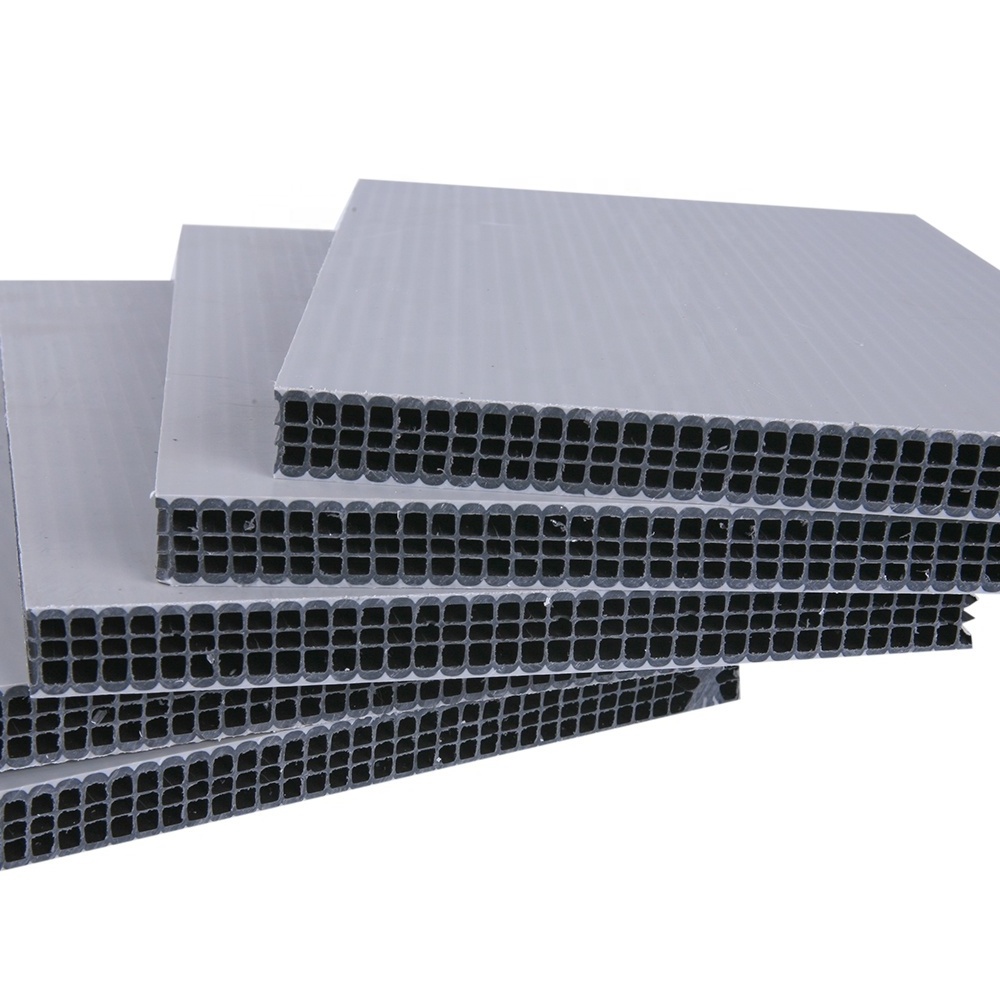

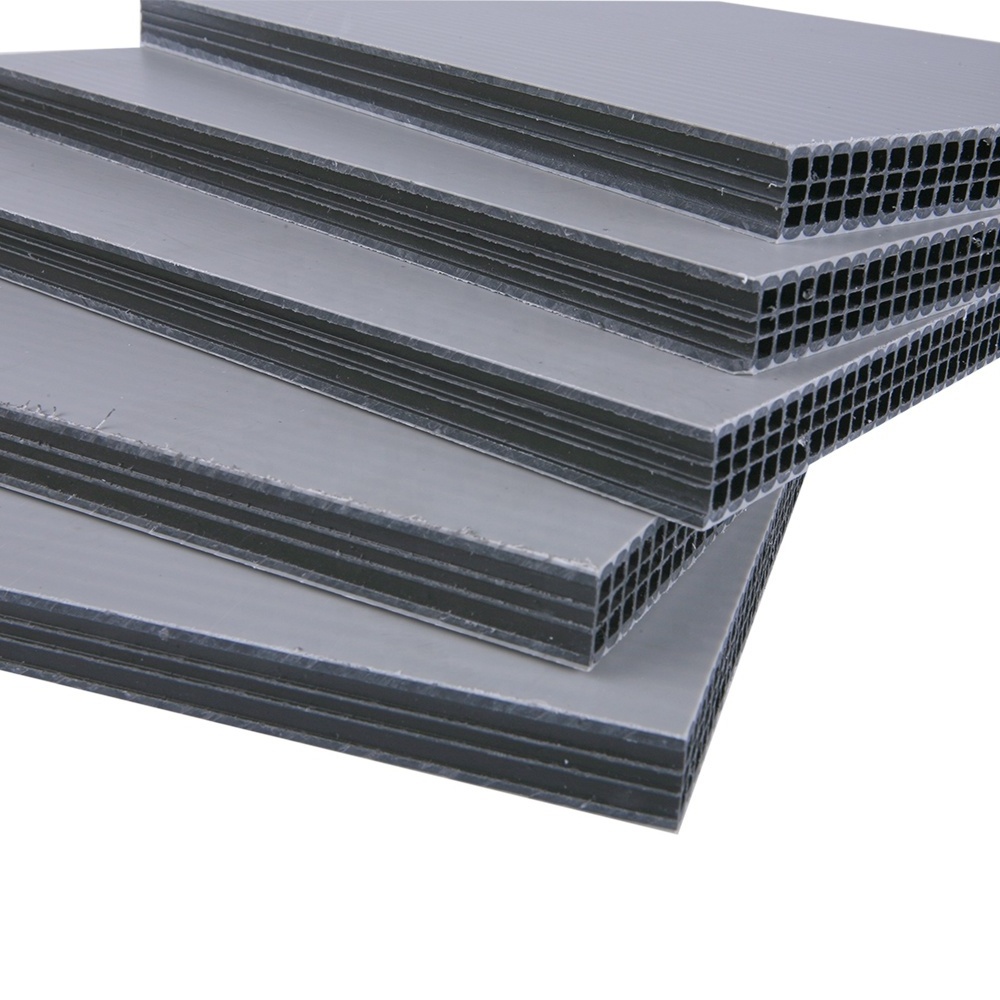

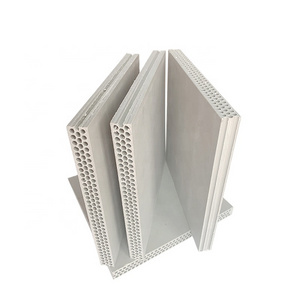

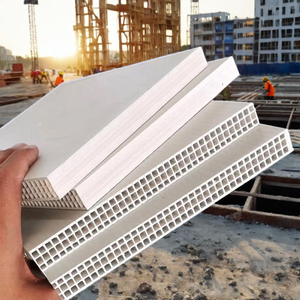

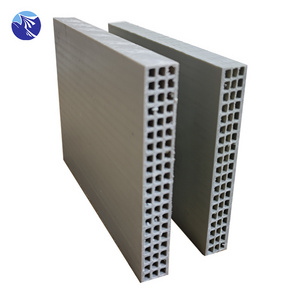

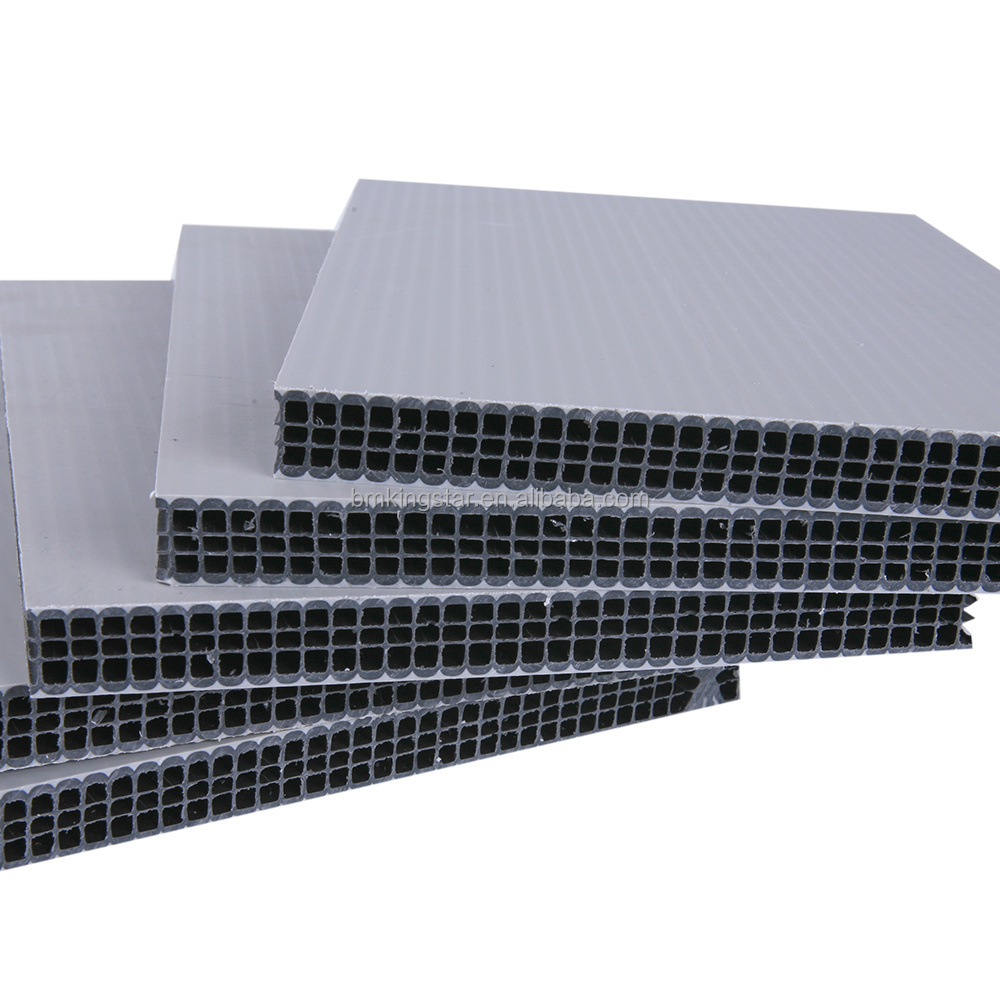

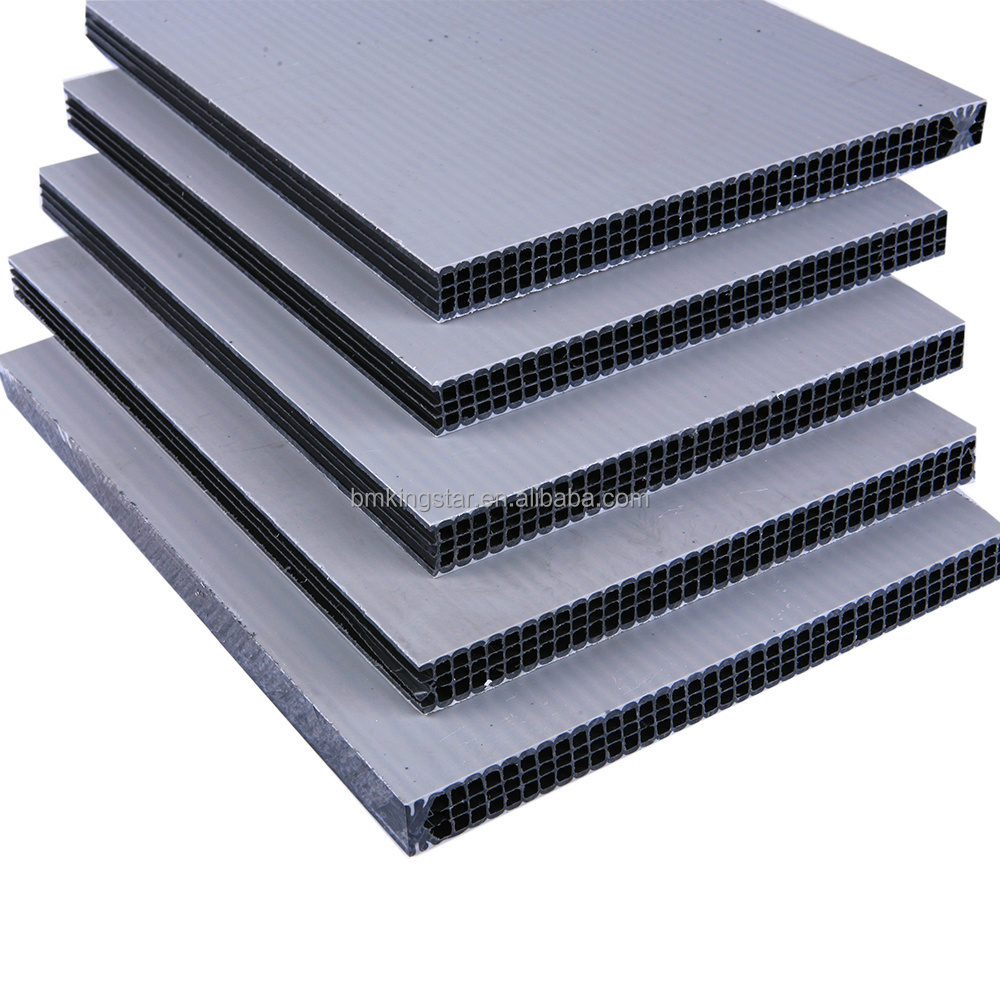

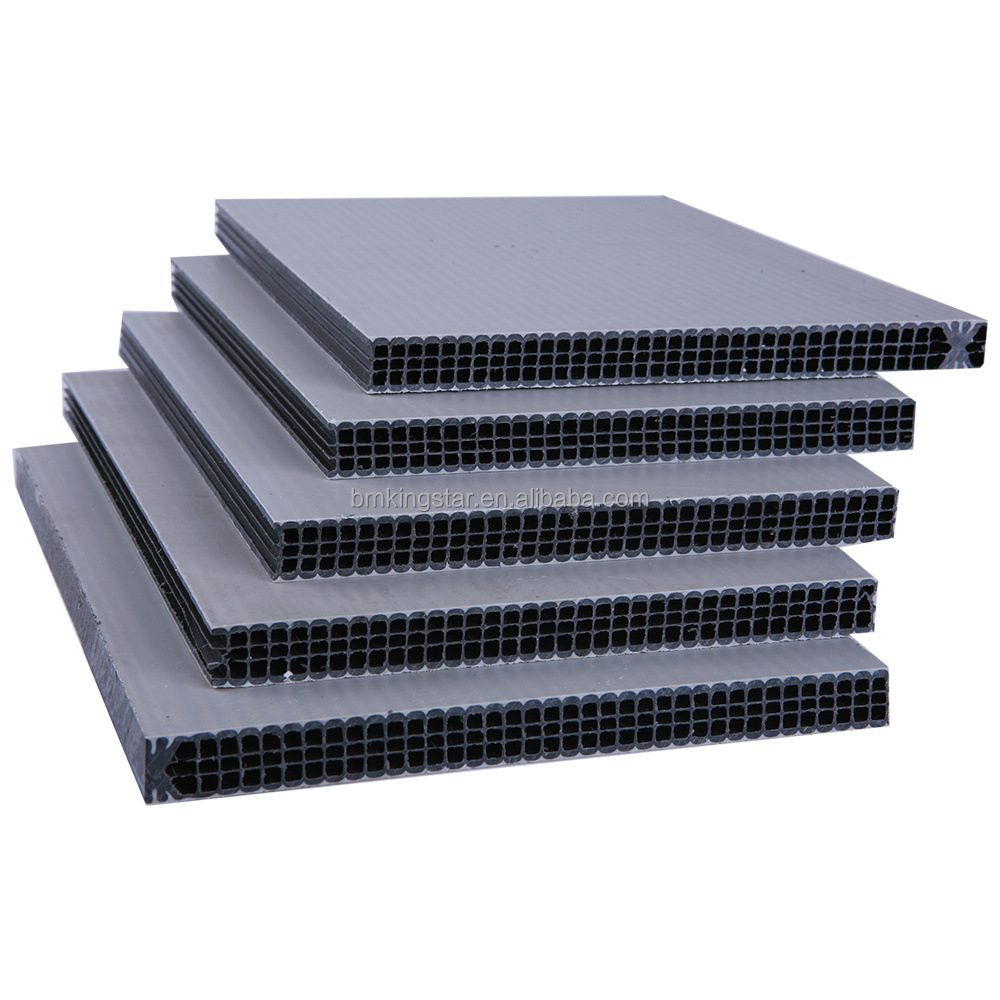

PP Hollow Plastic Formwork

-

Type:

-

PP plastic board

-

Color:

-

Grey, white,Black

-

Surface:

-

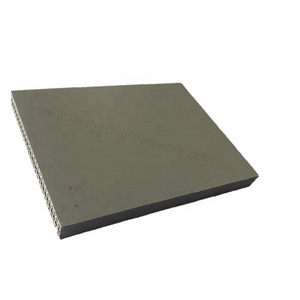

Glossy

-

Feature:

-

Waterproof Reusable

-

Application:

-

Construction

-

Tensile Strength:

-

81-130MPa

-

Water Absorption:

-

Less than 0.01%

-

Percentage of Contraction:

-

Less than 0.4%

Quick Details

-

Processing Service:

-

Cutting, Moulding, Sawing, Bolting, Drilling, Gluing, Warm bending, Cold curving Milling, Backing/laminating, Water-jet cutting Printing, Spray painting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGSTAR

-

Model Number:

-

KS-PVC Foam Board

-

Thickness:

-

12mm 15mm 18mm 20mm

-

Size:

-

1.22m*2.44m or Customization

-

Product name:

-

PP Hollow Plastic Formwork

-

Type:

-

PP plastic board

-

Color:

-

Grey, white,Black

-

Surface:

-

Glossy

-

Feature:

-

Waterproof Reusable

-

Application:

-

Construction

-

Tensile Strength:

-

81-130MPa

-

Water Absorption:

-

Less than 0.01%

-

Percentage of Contraction:

-

Less than 0.4%

|

Brand Name

|

KINGSTAR

|

|

Model Number

|

PP Hollow Plastic Formwork

|

|

Size

|

1.22m*2.44m, can be customized

|

|

Thickness

|

12mm 15mm 18mm 20mm

|

|

Density

|

0.55g/cm3

|

|

Material

|

PP

|

|

Surface

|

Glossy

|

|

Color

|

grey surface + black core, white surface + grey core

|

|

Packing

|

PE bag & Cartons & Wooden pallet

|

|

Sample

|

Be available (Contact for details)

|

|

Advantage

|

1) Lightweight Waterproof Fire retardant

2) High printability (digital and screen printing) 3) Weather Proof Anti-corrosive Non-Toxic Eco-friendly 4) Sound Insulation Shockproof Moistureproof Mouldproof 5) Easy to fabricate 6) Easy to storing and transporting |

Installation and Usage Instructions

1. The top plate of the plastic building template is used to lay 15mm thick. The vertical die of the shear wall can be 15mm based on the thickness and height of the wall.

2, the distance between the woods:

(1) roof plastic formwork support: Woods spacing is determined according to the thickness of floor concrete. In general construction conditions, the woods spacing (center distance) is less than 0.15m thickness, which is 200mm to 250mm.

(2) Supporting shear wall plastic templates: Woods spacing is adjusted by the all wall's height and thickness. For example, the wall height is 2800mm and the wall thickness is 300mm, when the 15mm thickness template is used, the vertical sub rib spacing is 150mm, and the shear wall and pillar width is more than 1 meters, the fixed frame must be added.

3. There is no gap between the shear wall and the column mould, and the part of the Yin angle (the bottom of the wall) must have a wooden side, which is convenient for the connection of the beam, the wall and the formwork. The shear wall formwork must be assembled into a whole after lifting, and then place a flat board , so to reduce labor intensity, and a good forming.

4. The edge of the plastic template is 15 ~ 30mm from the edge of the template. The strength of the nail is moderate and the length of the nail is generally 40 ~ 50mm, so it should not be too long or too short.

5, the wooden side of the floor of the beam must be left out of 1.5 centimeters, and the wall is standing on the mouth of the wooden square, so that it will not leak out the pulp and save the wall material.

markets. We have developed genuine cooperative relation with our customers from over 70 countries and regions over 16 years.

KINGSTAR is always devoted to build an excellent company to provide good quality products competitive prices and best service. We will constantly focus on improving ourselves by upholding the philosophy “Integrity, Innovation High-efficiency and Practicability”.

We are a leading manufacturer of specialized PVC ceiling panel, wall panel and door panel since 2007.

2. How many moulds do you have?

Our moulds cover almost all the popular size in different. And if you require special size, we can open new mould for you, and if your order is big enough, or it's our honor to be your regular manufacturer, we can delete the fee of your special mould.

3. What’s the best density board for making kitchen cabinets and cupboards?

The density 0.5-0.65g/cm3 are suitable for furniture making, price and quality demand will cause different chooses, the higher density, the better quality, the higher price.

4. Can we do painting on PVC foam sheet? Special painting material needed?

Yes. You can paint it into any patterns according to your market requirement.

The paint oil is different from the one for wood using, but it is easy to find since this material is getting popular. Please

kindly note that the board could not be painted under high temperature.

5. How can we do the edge?

There is various edge banding in the market, all are suitable for PVC Foam Board, such as PVC, Aluminum, Acrylic, and so on.

6. What’s the suitable using temperature of PVC foam Sheet?

-10℃~60℃ is the suitable using temperature for using, the sheet will get soft and twist under long time higher temperature environment.

7. How many designs do you have?

Our main surface treatments of the board are normal printing, high-glossy, hot stamping and laminating. Total designs we have are more than 2000 designs.

8. What thickness and sizes do you have?

Our thickness range is 1-40mm. Sizes we have 1220*2440mm, 1560*3050mm, 2050*3050mm, 915*1830mm, any sizes can be customized as per customer’s request.

9. What’s your MOQ?

Usually, our MOQ is about 50-100pcs. If we have stock, the MOQ can be less.

10. What colors can you do?

Usually, our normal color is white can brown color. We can also do other colors, such as red, blue green, yellow, orange,

grey,black etc..

11. What’s the application of PVC Foam Board?

PVC Foam Board is a perfect material for moisture environment. It can be used for Kitchen cabinet, Bathroom cabinet, Wardrobe,Door or other furniture. It can also used for construction concrete formwork, shuttering sheet; flooring or ceiling of the vehicle,advertising printing, Sign board and so on.

12. How many production lines do you have? And what’s the annual production capacity?

We have ten production lines. Our annual production capacity is about 30,000 tons.