- Product Details

- {{item.text}}

Quick Details

-

Process:

-

Lost Wax Casting/Precision Casting

-

Application:

-

Aviation, chemical industry, electric power, medical treatment

-

Material:

-

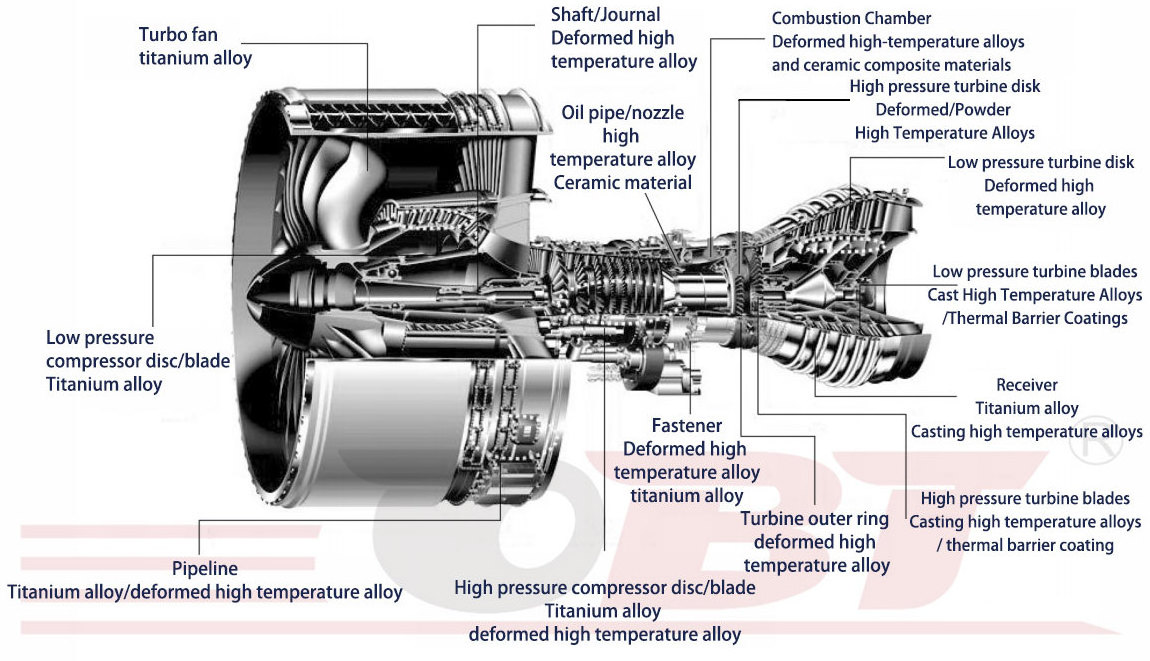

Titanium alloy/Nickel Alloy/Inconel

-

Surface treatment:

-

Polishing/Sand Blast/Spray-Paint etc.

-

Certification:

-

ISO9001:2015 Certified

-

Service:

-

OEM

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

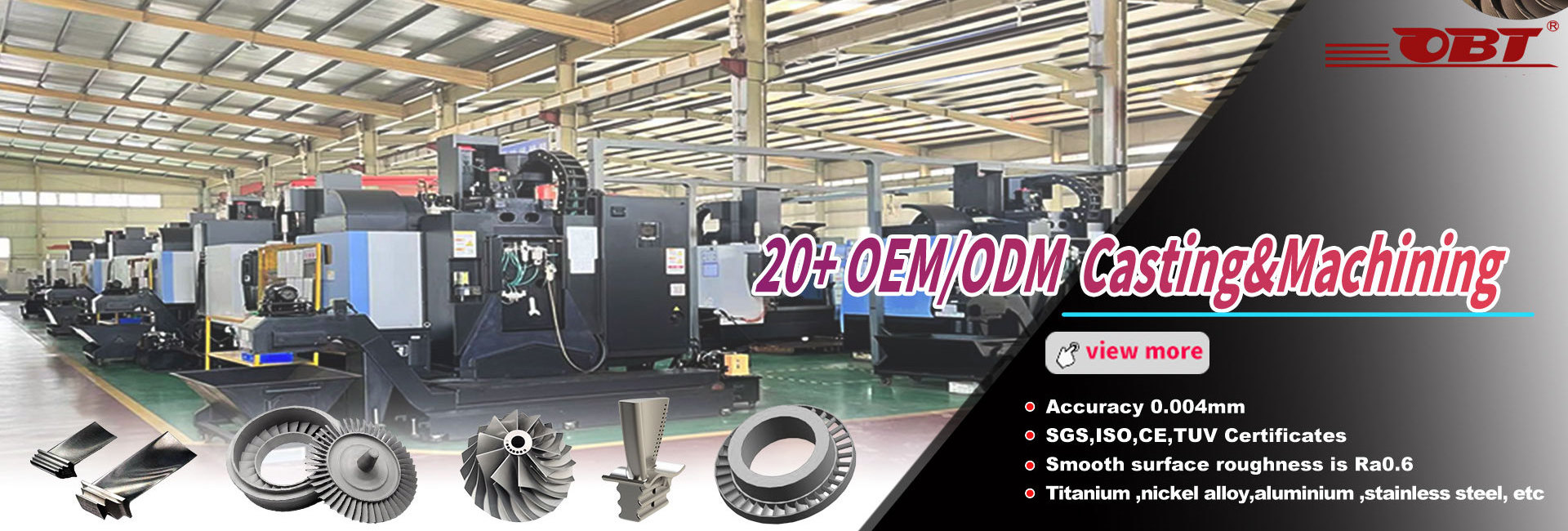

OBT

-

Model Number:

-

OBT-26

-

Process:

-

Lost Wax Casting/Precision Casting

-

Application:

-

Aviation, chemical industry, electric power, medical treatment

-

Material:

-

Titanium alloy/Nickel Alloy/Inconel

-

Surface treatment:

-

Polishing/Sand Blast/Spray-Paint etc.

-

Certification:

-

ISO9001:2015 Certified

-

Service:

-

OEM

Product Details

|

Product Name

|

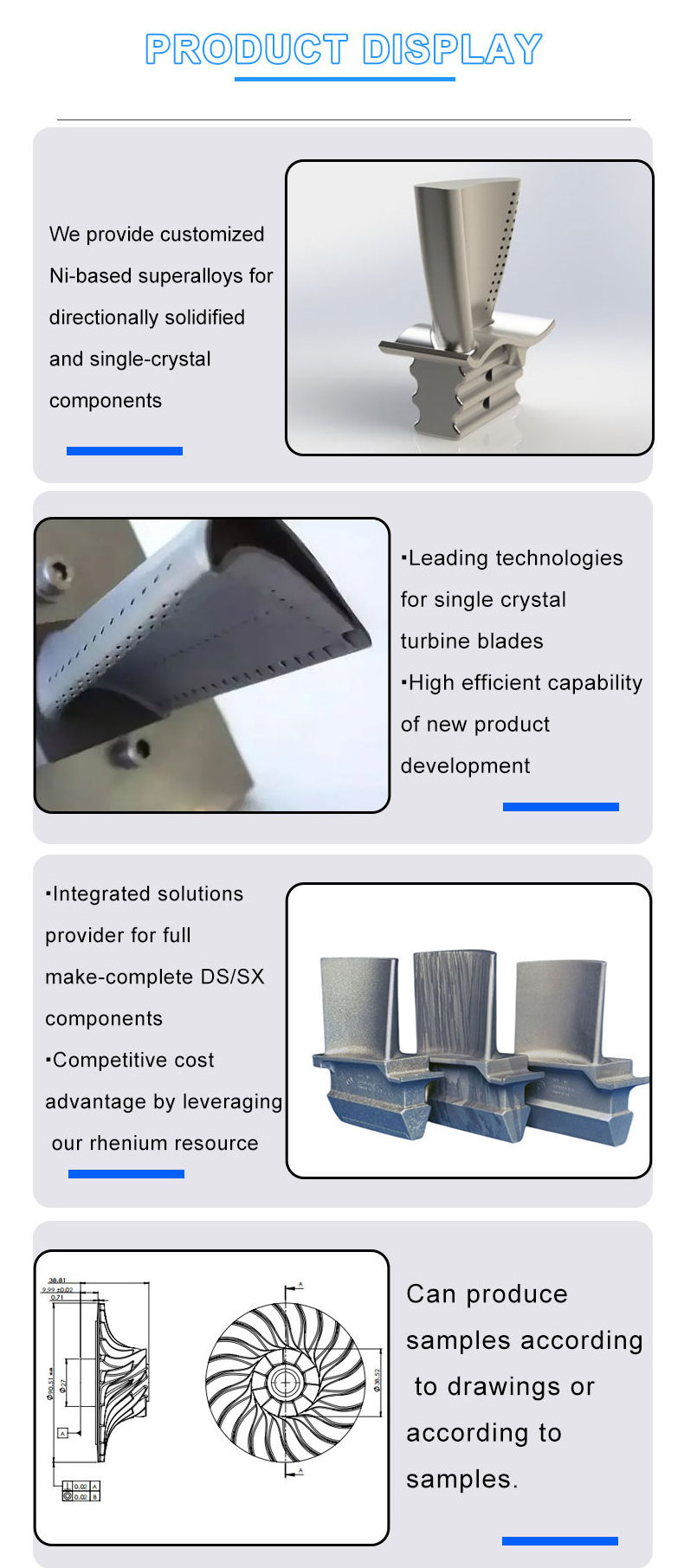

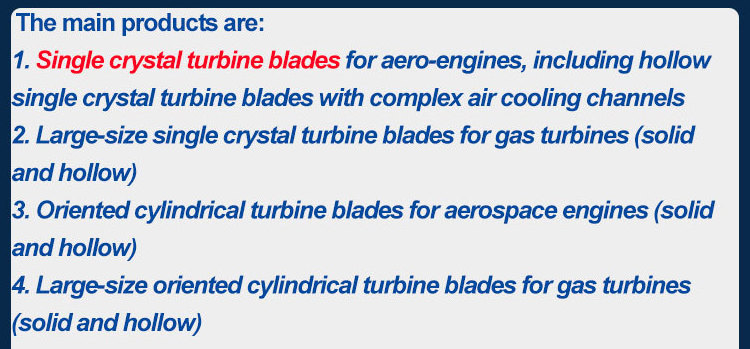

Single crystal blade Turbine blade Aircraft turbine blade High-temperature alloy casting

|

|

Material

|

Nickel based single crystal materials

|

|

Coating Technology

|

TBC:EB-PVD,APS DVC TBCS,PS

|

|

Appearance

|

Metallic luster, smooth surface without obvious grain boundaries or grain like structures

|

|

Introduction

|

Single crystal blades typically refer to a material used to manufacture high-temperature components in high-performance aircraft engines and industrial gas turbines. Single crystal blades are made of single crystal high-temperature alloys, which are usually nickel or cobalt based. Compared with traditional polycrystalline blades, single crystal blades have higher heat and corrosion resistance because their crystalline structure grows in one direction without grain boundaries. This design reduces the chances of fracture and oxidation, thereby improving the lifespan and performance of the components.

|

|

Features

|

1. High temperature resistance: Made of high-temperature alloy, capable of withstanding extreme combustion chamber temperatures

and pressures |

|

|

2. Antioxidation and corrosion resistance: It has excellent antioxidant and corrosion resistance performance

|

|

|

3. It has higher fracture resistance and mechanical strength, reducing damage caused by stress concentration.

|

|

|

4. Precision manufacturing: Adopting advanced manufacturing processes to ensure the accuracy and consistency of blade shape and

size. |

|

|

5. Lightweight design: lighter component weight improves engine fuel efficiency and performance.

|

|

|

6. Wide adaptability: It can be customized according to the requirements of different engines and industrial gas turbines to meet

different performance requirements and working environments. |

|

Tolerance

|

CNC Machining ±0.004mm/Casting ±0.1mm

|

|

Place of Origin

|

Qingdao, Shandong, China

|

|

Processing Craft

|

Sand Casting/Lost Wax Casting/Investment Casting/Vacuum Casting/Forging/CNC Machining/etc

|

|

Surface Treatment

|

A variety of surface treatments and coatings can be produced and customized according to your requirements.

|

|

Type

|

OEM; Customized

|

|

Certification

|

ISO9001:2015 Certified, UL Certification,GE,SGS,TUV,etc

|

|

Packing

|

Carton/Wooden box

|

|

Inspection

|

1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance.

|

|

|

2.Third Party inspection available upon requirement.

|

|

|

3.Optional X-ray detection

|

|

|

4.Fluorescence detection

|

|

Service

|

Drawing Custom

|

|

Mainly Testing Facility

|

Spectrometer,CMM, Tensile testing machine, Impact tester,Hardness tester,X-Ray,Salt spray test box, Pneumatic detection,UV

accelerated weathering tester,dynamic balancing, high-temperature tensile testing,fluorescence test,room temperature mechanical property testing and other testing. |

|

Quality Guarantee

|

2 Years

|

|

Features & Advantage

|

1.High machining accuracy, the flatness within 0.001mm

|

|

|

2.High finish appearance, smooth surface roughness is Ra0.6 after machining.

|

|

|

3.The machining precision is high and the assembly structure is seamless.

|

|

|

4.Smooth appearance, corrosion resistance.

|

|

|

5.Pass Salt Spray Test with 144 Hours.

|

|

Standard

|

ISO , DIN, AISI, ASTM, BS, JIS, etc.

|

|

|

GB/T 14992 GJB 5512.1 HB 7763 HB/Z 140

|

|

Payment

|

L/C,D/A,D/P,T/T,Western Union,Money Gram

|

Surface Coating Technology

|

Name

|

Inner Cavity Cooling Channel Coating

|

External Surface Coating

|

|

Nickel Aluminum Diffusion Coating

|

MTK-NAI

|

MTK-WAI

|

|

Aluminum Silicon Diffusion Coating

|

MTK-NAISi

|

MTK-JAISi

|

|

Chrome Aluminum Diffusion Coating

|

MTK-NAICr

|

MTK-WAICr

|

|

Diamond Aluminum Diffusion Coating

|

MTK-NAICo

|

MTK-WAICo

|

|

Platinum Aluminum Diffusion Coating

|

|

MTK-WPtAl

|

|

Aluminum Diffusion Coating

|

MTK-NAITi

|

MTK-WAITi

|

|

Q Salt Electroplating Platinum

|

|

MTK-WPt

|

|

Compressor Inorganic Phosphate Coating

|

|

MTK-WAI

|

|

MCrAIY Coating Technology

|

|

MTK-RZ

|

|

TBC

|

|

MTK-TBC

|

|

CVD Vapor Phase Aluminizing

|

|

|

|

Chromated Aluminum Coating Technology

|

|

|

Main materials:

|

Alloy Type

|

Alloy

|

US

|

|

Equiaxed Crystal Blades

|

K438

|

Inconel 738

|

|

|

K438G

|

K38G

|

|

|

K435

|

|

|

|

K488

|

|

|

|

K418

|

Inconel 713C

|

|

|

FSX-414

|

|

|

Oriented crystal blades

|

DZ38G

|

|

|

|

DZ411

|

|

|

|

DZ466

|

|

|

Single crystal blades

|

DD8

|

|

|

|

DD83

|

|

|

|

DD5

|

|

Hot Searches