- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

6500*1300*1400Mm

-

Weight:

-

9500 kg

-

Feeding width:

-

Customized

-

Product name:

-

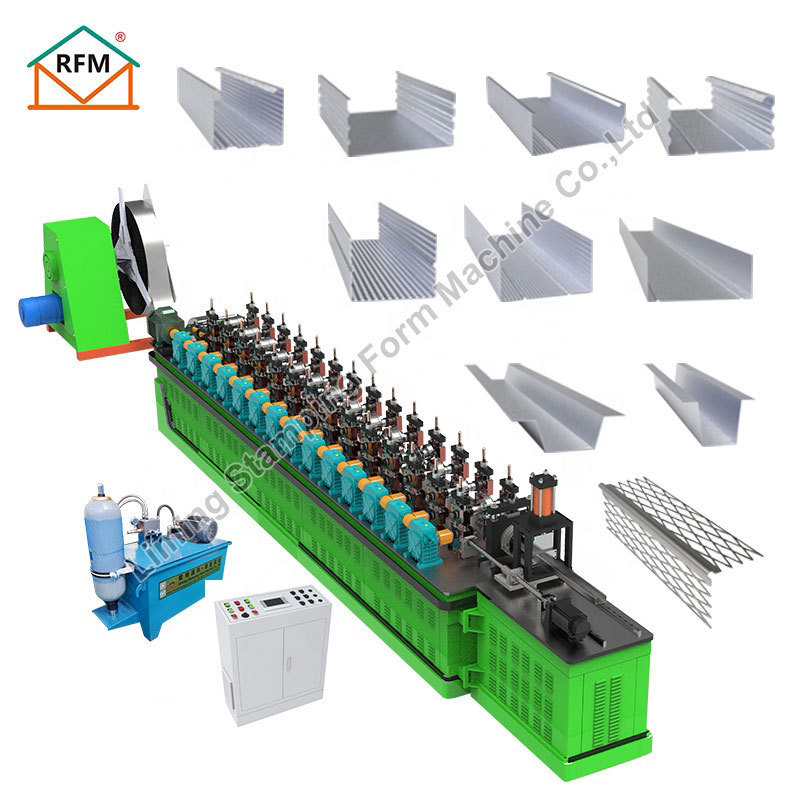

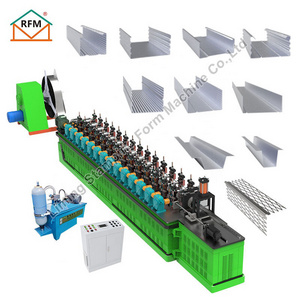

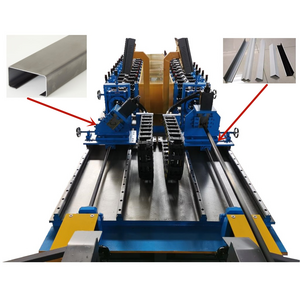

Stud and track roll forming machine

-

Roller material:

-

Cr 12

-

raw material:

-

PPGI PPGL GI GL

-

plc:

-

Delta / Siemens

-

Operation method:

-

Automatic

-

Production speed:

-

100-140m/min

-

Motor brand:

-

SIENEMS

-

cutting blade material:

-

SKD11

-

Color:

-

Client's Request

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

50-120m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

6500*1300*1400Mm

-

Weight:

-

9500 kg

-

Feeding width:

-

Customized

-

Product name:

-

Stud and track roll forming machine

-

Roller material:

-

Cr 12

-

raw material:

-

PPGI PPGL GI GL

-

plc:

-

Delta / Siemens

-

Operation method:

-

Automatic

-

Production speed:

-

100-140m/min

-

Motor brand:

-

SIENEMS

-

cutting blade material:

-

SKD11

-

Color:

-

Client's Request

We are factory for 26 years, contact us for latest discounted price!

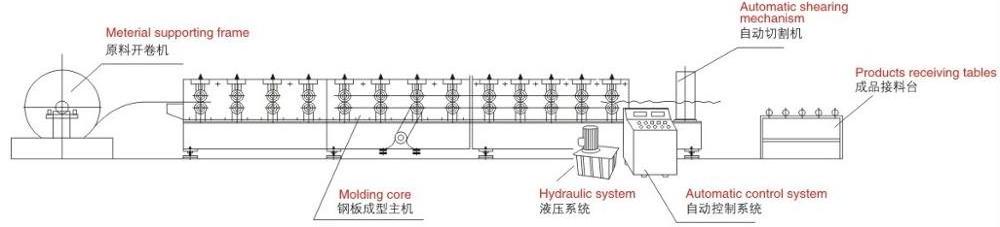

The complete production process is the basis for your choice of machine

Machine attributes

Uncoiling —— Material Feeding —— Roll Forming —— Step Making —— Automatic Cutting —— Products Receiving

Uncoiling —— Material Feeding —— Roll Forming —— Step Making —— Automatic Cutting —— Products Receiving

|

Stud and track roll forming machine configuration components

|

|

|

||

|

Name

|

Quantity

|

Units

|

||

|

Double head hydraulic uncoiler

|

1

|

Set

|

||

|

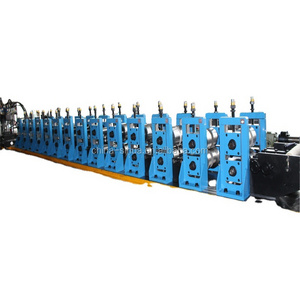

Siemens motor drive

|

1

|

Set

|

||

|

Adjustable feeding platform

|

1

|

Set

|

||

|

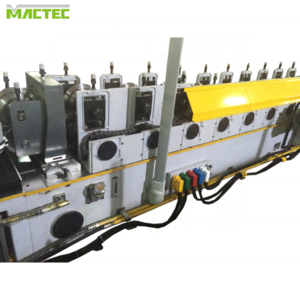

Roll forming system

|

1

|

Set

|

||

|

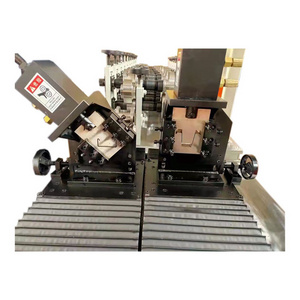

Servo non-stop cutting

|

1

|

Set

|

||

|

Hydraulic system

|

1

|

Set

|

||

|

Delta PLC electronic control system

|

1

|

Set

|

||

|

Supporter/Automatic Stacker

|

1

|

Set

|

||

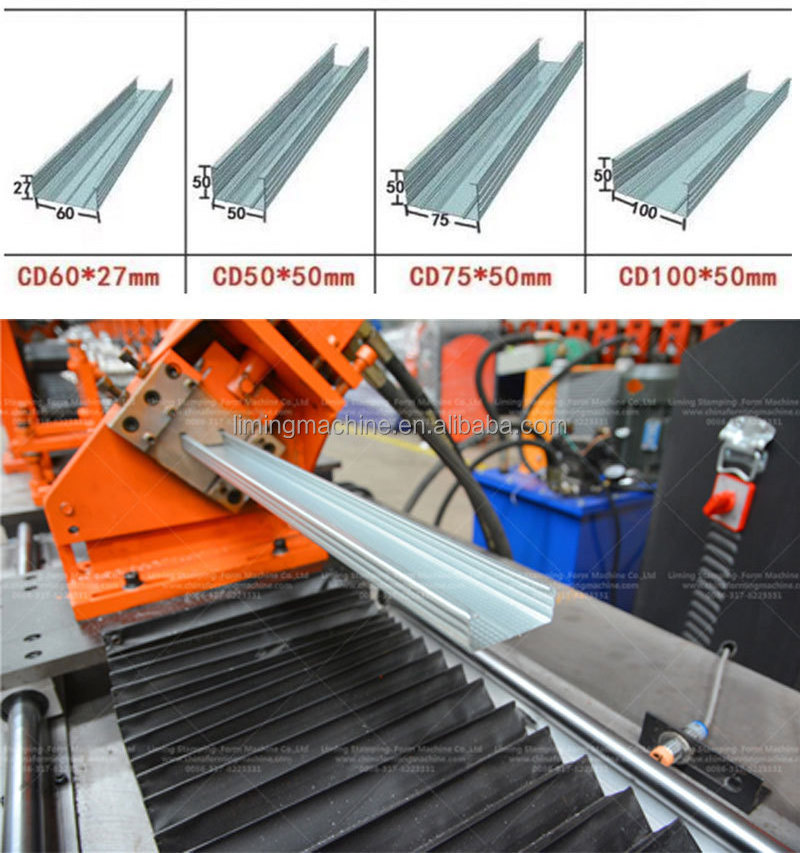

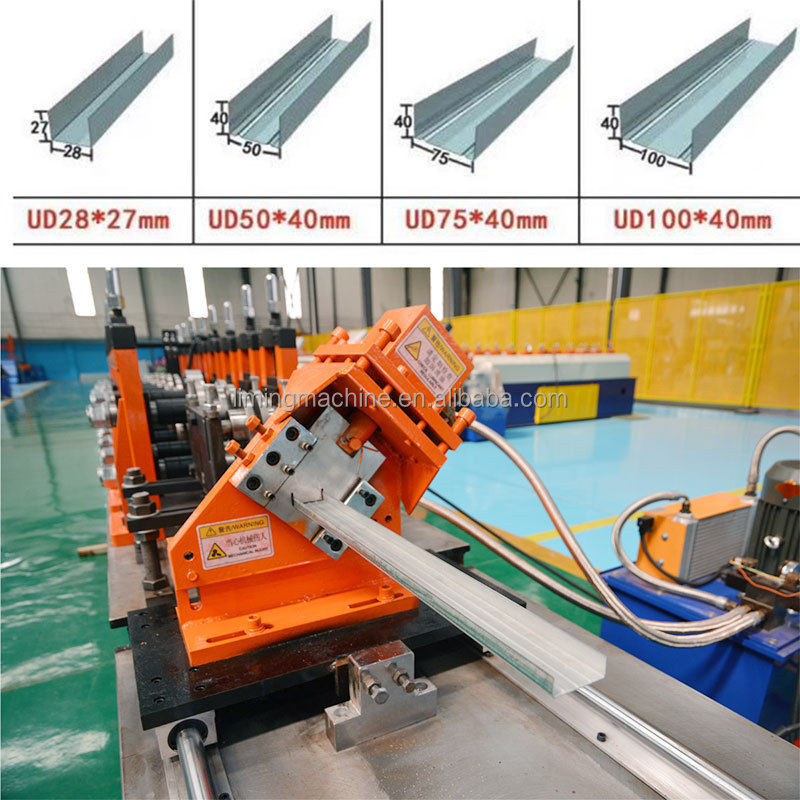

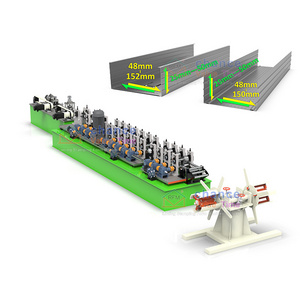

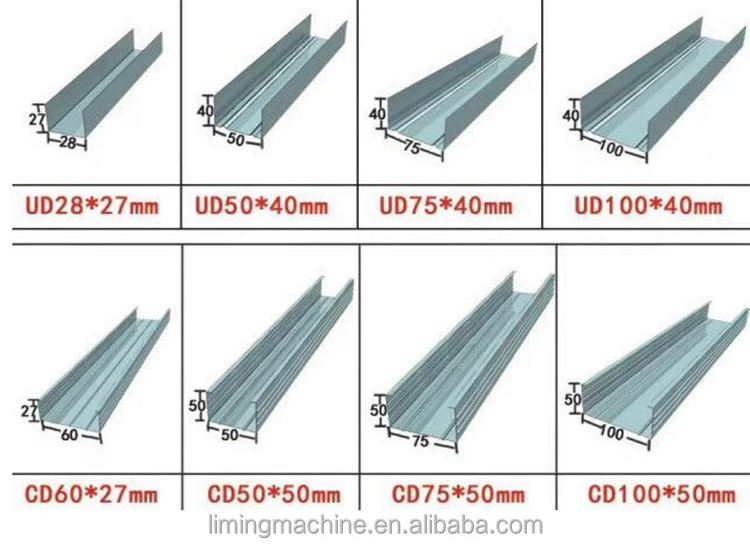

Choice of standard EU size or custom size

More profile options

1. Angle bead roll forming machine

Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine

Corner bead forming machine sells well in many countries, the common version outline is as above, the size includes 20*20mm, 25*25mm, 27*27mm, 30*30mm. Product thickness is usually between 0.3-0.6mm

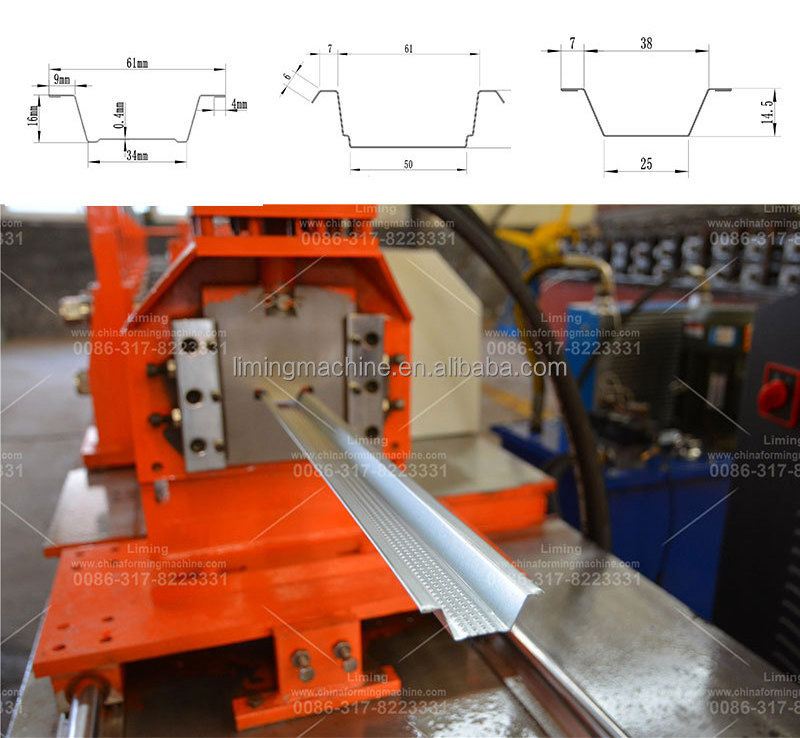

2. Omega profile roll forming machine

Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.7 mm, we sell a large number of such machines to Peru, Mexico, UAE, Chile, South Africa, etc. and sell well in this region

3.T grid roll forming machine

Spring T grid machine |T bar rolling machine | Main T machine | Cross T ceiling keel machine

T grid roll forming machines are popular in many countries, the common size:

Main grid roll forming machine: 24x38, 24x32, 14x32

cross grid roll forming machine: 24x28, 24x25, 14x25

4.Cassette universal keel forming machine

Universal ceiling keel machine, cassette keel forming machine

Cassette keel partition wall has the functions of light weight, high strength, waterproof, shockproof, dustproof, sound insulation, sound absorption, constant temperature, etc.

More products

Hot Searches