- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

faygo

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Weight:

-

2-10T

-

Name:

-

PVC Pipe Production Line

-

Color:

-

White

-

Inverter:

-

ABB

-

Contactor:

-

Siemens

-

Temperature Control Meter:

-

ROMON

-

Motor:

-

Siemens

-

Raw material:

-

stainless steel

-

Heater material:

-

Foundry Aluminum

-

Automatic Grade:

-

Automatic

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

40 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

faygo

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Weight:

-

2-10T

-

Name:

-

PVC Pipe Production Line

-

Color:

-

White

-

Inverter:

-

ABB

-

Contactor:

-

Siemens

-

Temperature Control Meter:

-

ROMON

-

Motor:

-

Siemens

-

Raw material:

-

stainless steel

-

Heater material:

-

Foundry Aluminum

-

Automatic Grade:

-

Automatic

-

Certification:

-

CE ISO

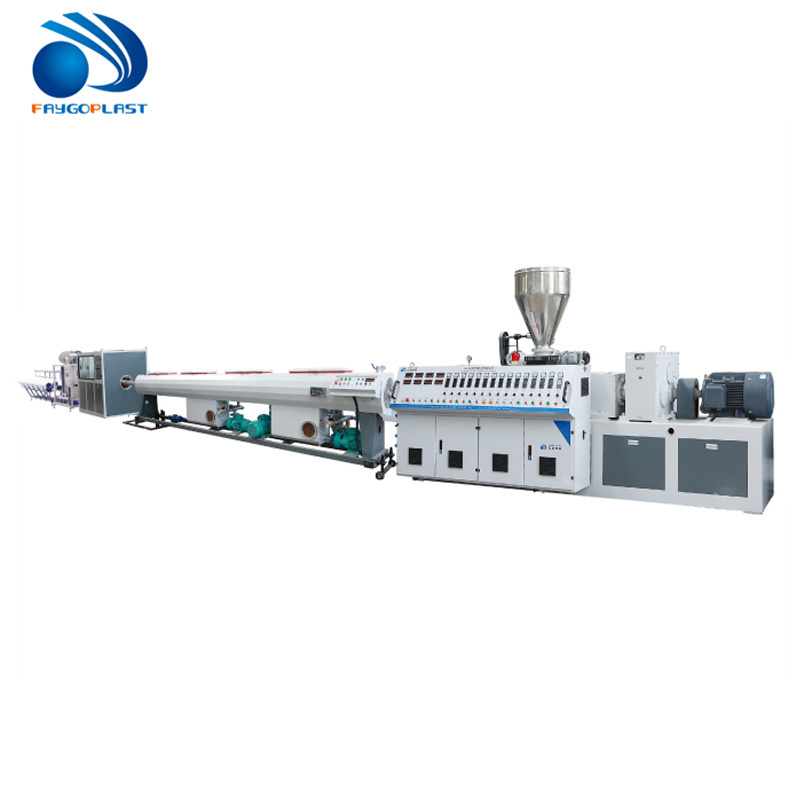

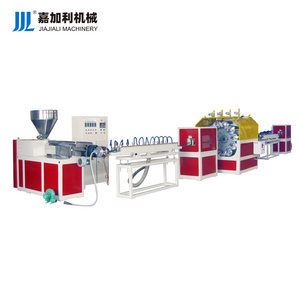

PVC Pipe Production Line

This line is mainly used for producing UPVC pipes with large diameters and different pipe wall thickness in the aspects such as the agricultural and constructional plumbing, cable layietc. The max diameter of pipe could be 1200mm.

|

model |

FGP160 |

FGP250 |

FGP315 |

FGP630 |

FGP800 |

|

pipe size |

50~160mm |

75~250mm |

110~315mm |

315~630mm |

500~800mm |

|

extruder |

SJZ65/132 |

SJZ80/156 |

SJZ92/188 |

SJZ92/188 |

SJZ92/188 |

|

motor power |

37kw |

55kw |

90kw |

110kw |

132kw |

|

output |

250kg |

350kg |

550kg |

600kg |

700kg |

Advantages:

The process flow of this line as blow:

PVC powder + additive --- mixing---material feeder---twin screw extruder---mould and calibrator---vacuum forming machine---spraying cooling machine---haul-off machine---cutting machine---discharge rack or pipe belling machine.

The screw of extruder has advanced design, which provide powerful safeguard for the PVC plasticization, and the Siemens PLC control system make more convinient operation. The degassing system will ensure the quality of final PVC pipes.

The tank body of vacuum calibration and cooling units adopt stainless 304# steel, multi-sections vacuum system ensures the stable sizing and cooling for pipes; Special cooling system improves the cooling efficiency; Auto water temperature control system make the machine more intelligent.

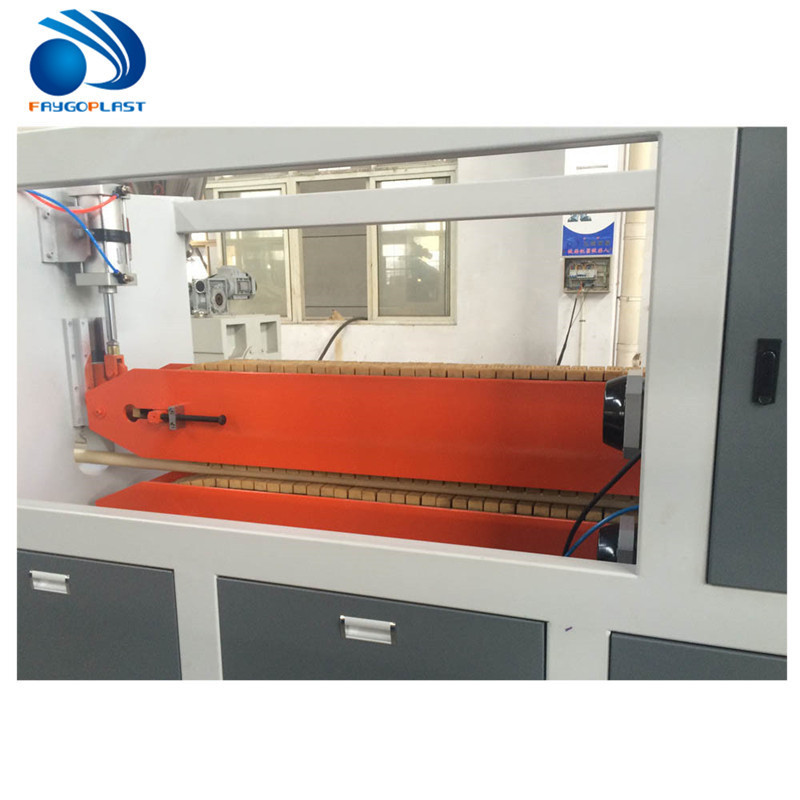

For different pipe size, the haul-off machine will adopt two caterpillars, three caterpillars, four caterpillars, six caterpillars are designed for different requirements. Pedrail clamping uses mechanical and pneumatic combining system, which is more reliable in performance

Cutting system adopts no-dust cutter or planetary cutting means; There is dust-collecting system ensures clean working environment.