- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

/

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

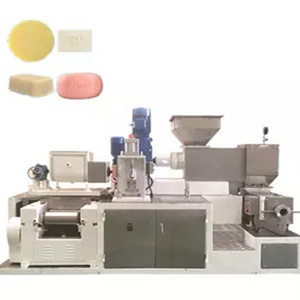

Automatic soap making machine

-

Main Function:

-

Automatic Form

-

Material:

-

Carbon Steel

-

Mixer capacity:

-

70kg/batch

-

Soap fined machine capacity:

-

1000kg/h

-

Three roller mill power:

-

7.5kw

-

Double vacuum plodder machine capacity:

-

500-800kg/h

-

Printing speed:

-

60-120pcs/min

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Marketing Type:

-

Hot Product

-

Warranty:

-

/

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Automatic soap making machine

-

Main Function:

-

Automatic Form

-

Material:

-

Carbon Steel

-

Mixer capacity:

-

70kg/batch

-

Soap fined machine capacity:

-

1000kg/h

-

Three roller mill power:

-

7.5kw

-

Double vacuum plodder machine capacity:

-

500-800kg/h

-

Printing speed:

-

60-120pcs/min

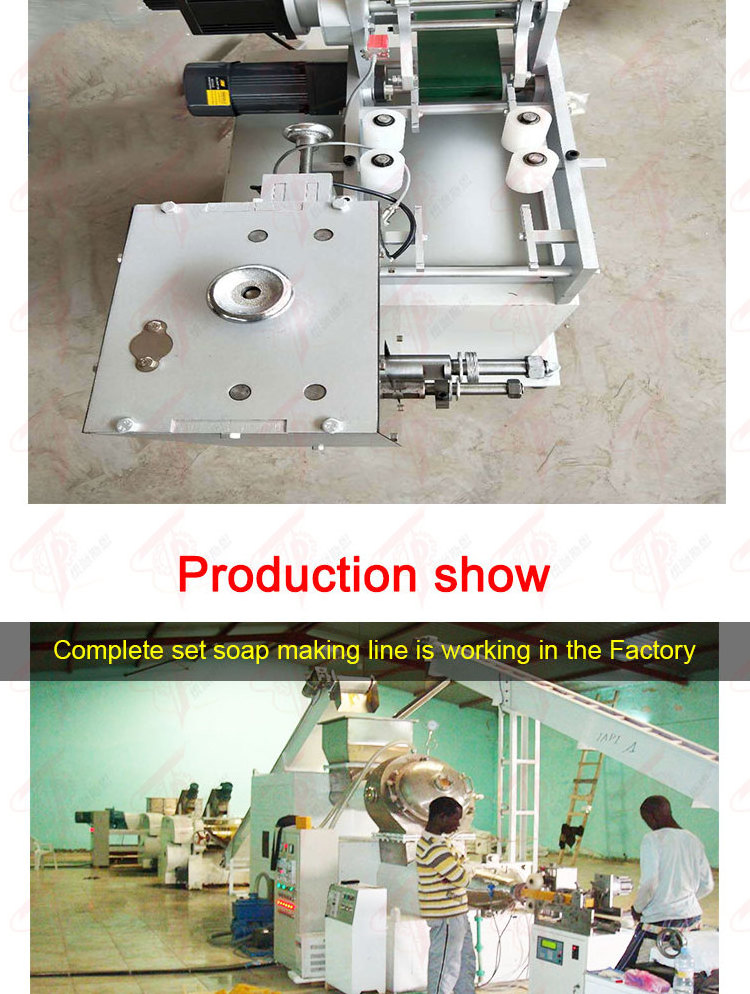

TOPCN Fully automatic soap making machine Steps :

1: put the soap tablets or soap tablets into the mixer, start the mixer, and then put the flavor, pigment, other accessories, preservatives, etc. evenly, open the material valve, put the material into the silo, wait Mixer.

2: start the first conveyor and the first three-roll mill, and then open the silo valve, let the material into the conveyor to the grinding machine grinding.

3: Start the second and third conveyors and the second three-roll mill. laundry bar soap making machine

4: Wait for the material into the double vacuum after the machine, confirmed that continuous production, start the first screw, start the second screw after the material. machine for making soap

5: Wait for the article. Start the printer and the fourth conveyor to confirm the print speed

and the same speed, the good soap loading, soap head and poor access to the conveyor back into the machine.

|

Name |

Qty |

Technology parameter |

|

Model: 70 mixer |

1 |

Mixing various raw materials for producing soap and transparent soap thoroughly and evenly,to refine neat soap, and completely mix various auxiliary materials and additives and flavors into neat soap to reach the recipe requirements. Capacity:70kg/batch |

|

Soap Fined machine |

1 |

Capacity:1000kg/h Motor:15Kw Size:2600*1200*1700 Weight:1100Kw |

|

S260 three roller mill |

1 |

Roller diameter:260mm Working face length:695mm Power:7.5kw Dimension:1650*1350*1100mm Weight:2300kg |

|

C245double vacuum plodder machine |

1 |

Capacity:500-800kg/h Powder:7.5kw/15kw Dimensions:4000*1000*2450mm Weight:2570kg |

|

Soap printer |

1 |

Capacity:60-120pcs/min Power:2.2Kw Weight:1000kg Dimension:1450*800*1100mm |

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2.TERMS OF PAYMENT

BY 40 % IN ANVANCED, THE BALANCE 6 0% BY T/T BEFORE SHIPMENT

3.PRICE VALID UNTIL

30 DAYS.

4. PACKING: WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5.PORT OF SHIPMENT

GUANGZHOU PORT

1.WARRANTY

THE SELLER WARRANTY THE MACHINE FOR ONE YEAR, AND SUPPLY ONE YEAR FREE SPARE PARTS WITH THE MACHINE.

2.TERMS FOR INSTALLATIONS,STARTING-UP AND ADJUSTMENT.

THE SELLER SHOULD SEND ENGINEERS TO CARRY OUT INSTALLATION AND DEBUGGING OF THE EQUIPMENT IN BUYER’S PLACE IF REQUESTED. THE COST FOR INTERNATIONAL DOUBLE WAYS AIR TICKETS SHALL BE PAID BY BUYER FOR THE ENGINEER. BUYER SHALL

COOPERATE WITH SUPPLIER’S ENGINEER AND MAKE ALL THE INSTALLATION CONDITION READY TO WORK. SUCH AS”WATER, ELECTRICITY,RAW MATERIAL ETC.

3.OPERATION MANUAL

THE OPERATION MANUL WILL BE SHIPPED WITH THE GOODS AND IN ENGLISH VERSION.