- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

32--121KW

-

Weight:

-

500 kg

-

Capacity:

-

1000PCS/H-5000PCS/H

-

Total Power:

-

32kw-121kw

-

Water:

-

Recyclable

-

Pool:

-

Homogenizing Pool, Supply Pool and Storage Pool

-

Egg Cartons Size:

-

29.5cm*29.5cm*46mm

-

Mould:

-

Can Be Customized

-

Color:

-

Colorful

-

Waterproof:

-

Can Be Customized

-

Machine type:

-

Egg Tray Making Mahine

-

Processing Material:

-

Waste Paper Pulp Molding

Quick Details

-

Production Capacity:

-

100 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SL

-

Voltage:

-

220V/380V

-

Power:

-

32--121KW

-

Weight:

-

500 kg

-

Capacity:

-

1000PCS/H-5000PCS/H

-

Total Power:

-

32kw-121kw

-

Water:

-

Recyclable

-

Pool:

-

Homogenizing Pool, Supply Pool and Storage Pool

-

Egg Cartons Size:

-

29.5cm*29.5cm*46mm

-

Mould:

-

Can Be Customized

-

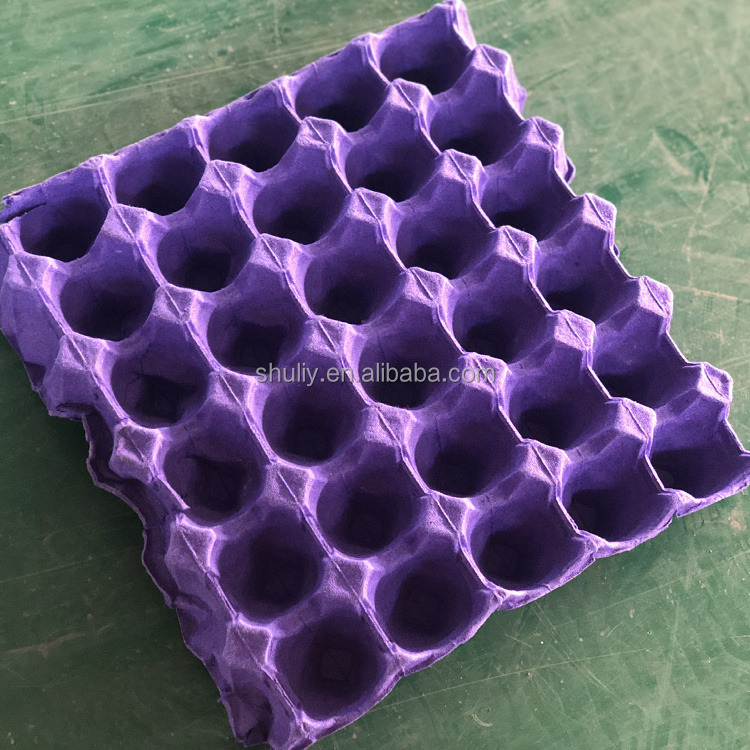

Color:

-

Colorful

-

Waterproof:

-

Can Be Customized

-

Machine type:

-

Egg Tray Making Mahine

-

Processing Material:

-

Waste Paper Pulp Molding

Paper Pulp Tray Machine Egg Carton Making Machine Egg Tray Machine Price

The paper mold egg tray has a loose material and a unique egg-shaped curved surface structure, and has better air permeability, freshness and excellent cushioning and positioning. During the long-distance transportation, the damage rate of the egg can be changed by the traditional packaging. 8%-10% reduced to 2%.

Product Parameter

| Model | SL-1*3 | SL-1*4 | SL-3*4 | SL-4*4 | SL-3*8 | SL-4*8 | SL-5*8 |

| Capacity | 1000pcs/h | 1500pcs/h | 2000pcs/h | 2500pcs/h | 3000pcs/h | 4000pcs/h | 5000pcs/h |

| Total Power | 32kw | 40kw | 65kw | 82kw | 95kw | 112kw | 121kw |

| Paper Consumption | 80kg/h | 120kg/h | 160kg/h | 200kg/h | 240kg/h | 320kg/h | 400kg/h |

| Water Consumption | 160kg/h | 240kg/h | 320kg/h | 400kg/h | 480kg/h | 640kg/h | 800kg/h |

| Electric Consumption | 18kw/h | 32kw/h | 45kw/h | 58kw/h | 65kw/h | 78kw/h | 95kw/h |

| Worker | 3-4 | 3-4 | 4-5 | 4-5 | 5-6 | 3-4 | 3-4 |

1.Pulp molding automatic egg tray production line mainly uses waste paper as raw material, which is rich in source and low in price, which belongs to the comprehensive development and utilization of waste.

2.Waste utilization, low cost. Most of the raw materials can be obtained directly from waste paper factories and garbage dumps, and the cost is low. High economic efficiency.

The main function of the egg tray is shock absorption. Separate items, such as fragile items, to reduce the rate of breakage of items during transportation or storage.

The egg tray machine can make a various shaped product, such as egg tray, fresh fruit tray, electric inner tray, a fragile product tray, farm tray, food and packing, product, special industry tray packaging, etc.

1. Can the egg tray machine make other trays of different specifications?

A.Yes, as long as the abrasive tools are customized according to customer requirements.

2.What are the materials of the abrasive tools?

A.The egg tray mill is made of aluminum and plastic, and the net is stainless steel. If you make special-shaped abrasive tools, they must be aluminum abrasive tools.

3. Can you make egg trays of different colors?

A.Yes, just add different pigments in the slurry tank.

4. What output of machines do you provide?

A.The output of our machine ranges from 1000pcs/h to 5000pcs/h, which can fully meet your needs.

5. Is the mold of the machine fixed?

A.We can customize the mold according to your requirements.

6. What is the ratio of paper to water in the pulper?

A. 1:5

7. How many pools does the customer need to build during the installation process?

A.3 (homogenization tank, slurry supply tank, storage tank)

8. How many meters does the brick kiln dry?

A.The machine with a 1,000-piece output is 25m, and the large output is generally 40-50m