Our machines can reach the maximum paper width 2110mm

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

200/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Wylong

-

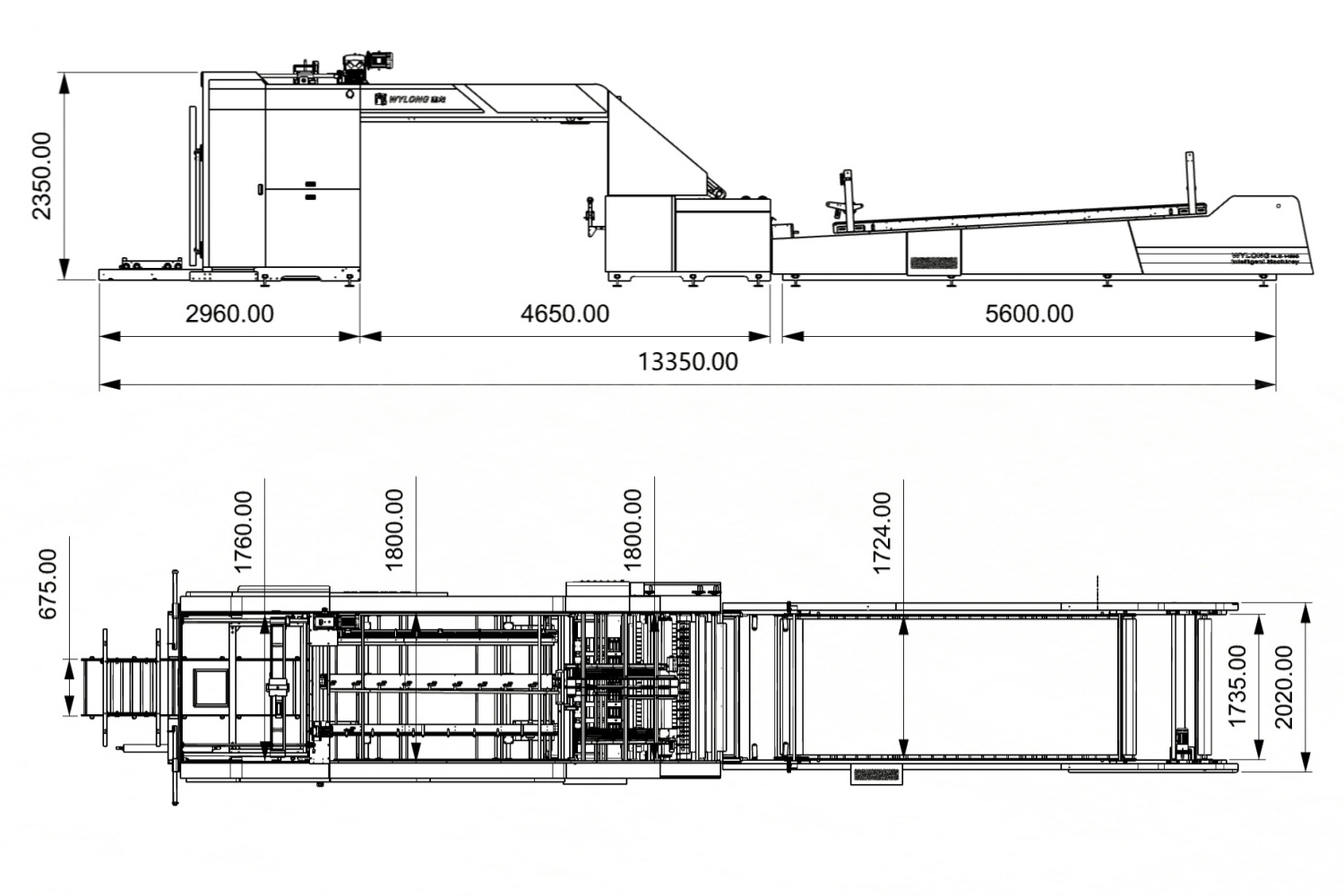

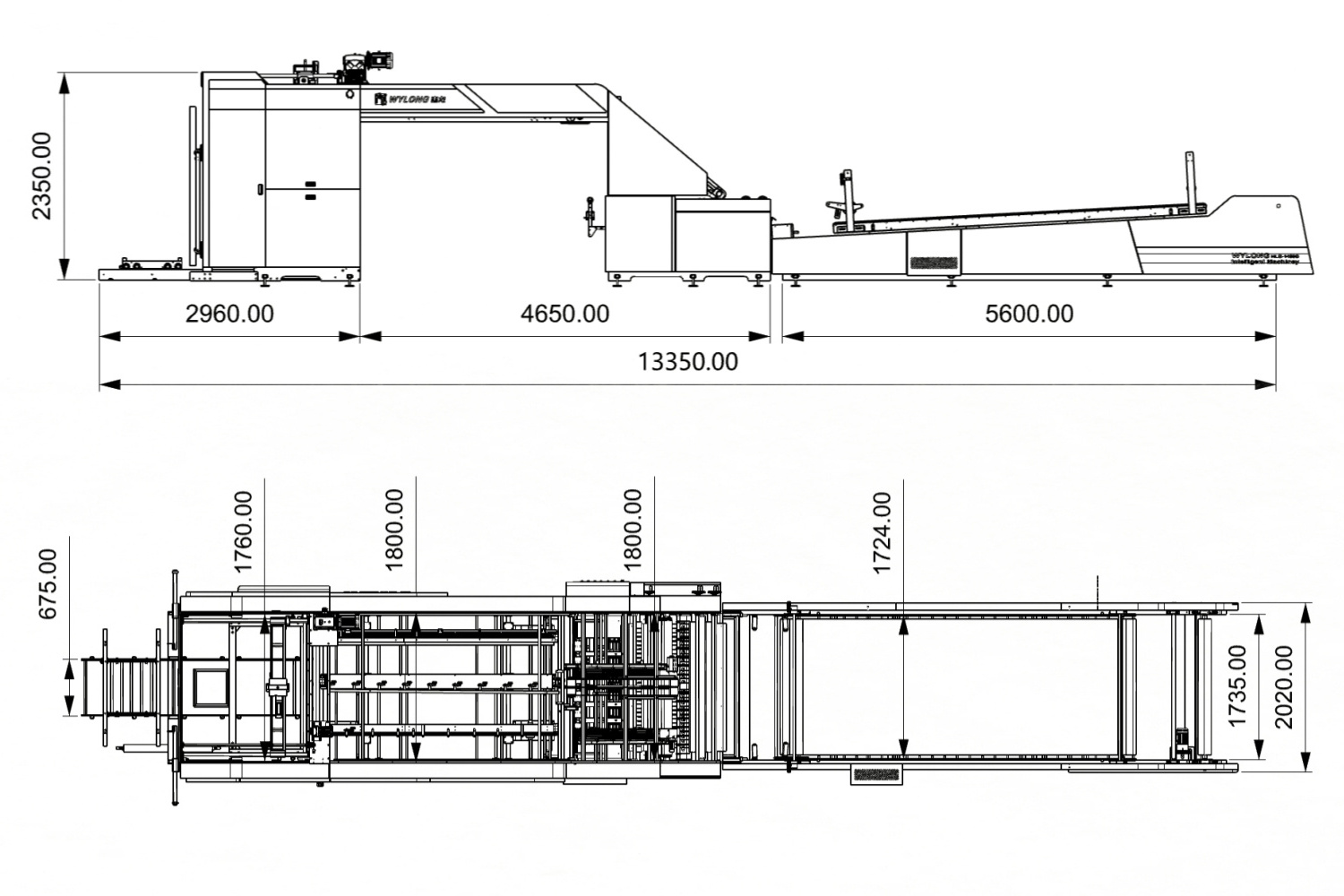

Dimension(L*W*H):

-

15.7x2.2x2.6m

-

Weight:

-

7000 KG

-

Product Model:

-

HLG-1680

-

Max. Sheet Size:

-

1450*1450mm

-

Min. Sheet Size:

-

450*350mm

-

Power:

-

220/380V 22KW

-

Thickness Of Upper Paper:

-

150-600g/m2

-

Thickness Of Bottom Paper:

-

200-1500g/m2

-

Laminate Error:

-

+_0.5mm

-

Operation Space:

-

3mx12m

-

Max. Speed:

-

100-150pcs/min

-

Weight/Dimension:

-

7000KGS/9x1.9x2.2m

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic

-

Driven Type:

-

Electric

-

Voltage:

-

200/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Wylong

-

Dimension(L*W*H):

-

15.7x2.2x2.6m

-

Weight:

-

7000 KG

-

Product Model:

-

HLG-1680

-

Max. Sheet Size:

-

1450*1450mm

-

Min. Sheet Size:

-

450*350mm

-

Power:

-

220/380V 22KW

-

Thickness Of Upper Paper:

-

150-600g/m2

-

Thickness Of Bottom Paper:

-

200-1500g/m2

-

Laminate Error:

-

+_0.5mm

-

Operation Space:

-

3mx12m

-

Max. Speed:

-

100-150pcs/min

-

Weight/Dimension:

-

7000KGS/9x1.9x2.2m

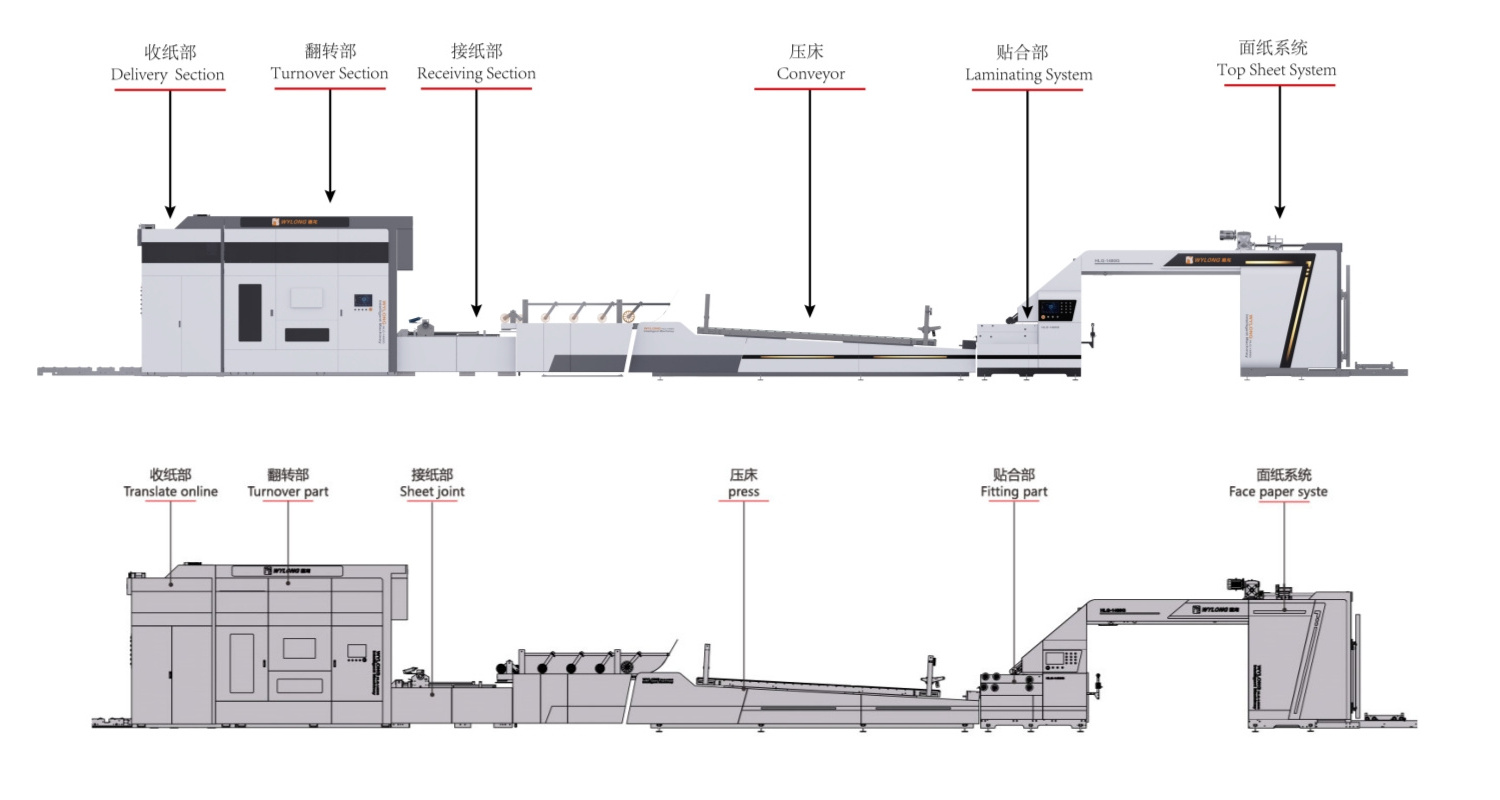

Products Description

Product Paramenters

|

Model

|

HLG-1480G

|

HLG-1680G

|

|

Max.sheet(wxl)

|

1480X1480mm

|

1650x1650mm

|

|

Min.Sheet(wxl)

|

450x350mm

|

450x350mm

|

|

Thickness of upper paper

|

150-600g/㎡

|

150-600g/㎡

|

|

Thickness of bottom paper

|

≤10mmA-FCorrugated paper,300grams of cardboard

|

≤10mmA-FCorrugated paper,300grams of cardboard

|

|

Machine speed

|

12000P/H

|

12000P/H

|

|

Accuracy

|

±1mm

|

±1mm

|

|

Machine space

|

157000x2200x2600mm

|

161000x2400x2600mm

|

|

Weights

|

7000kg

|

7800kg

|

|

Power

|

22kw/380v

|

26kw/380v

|

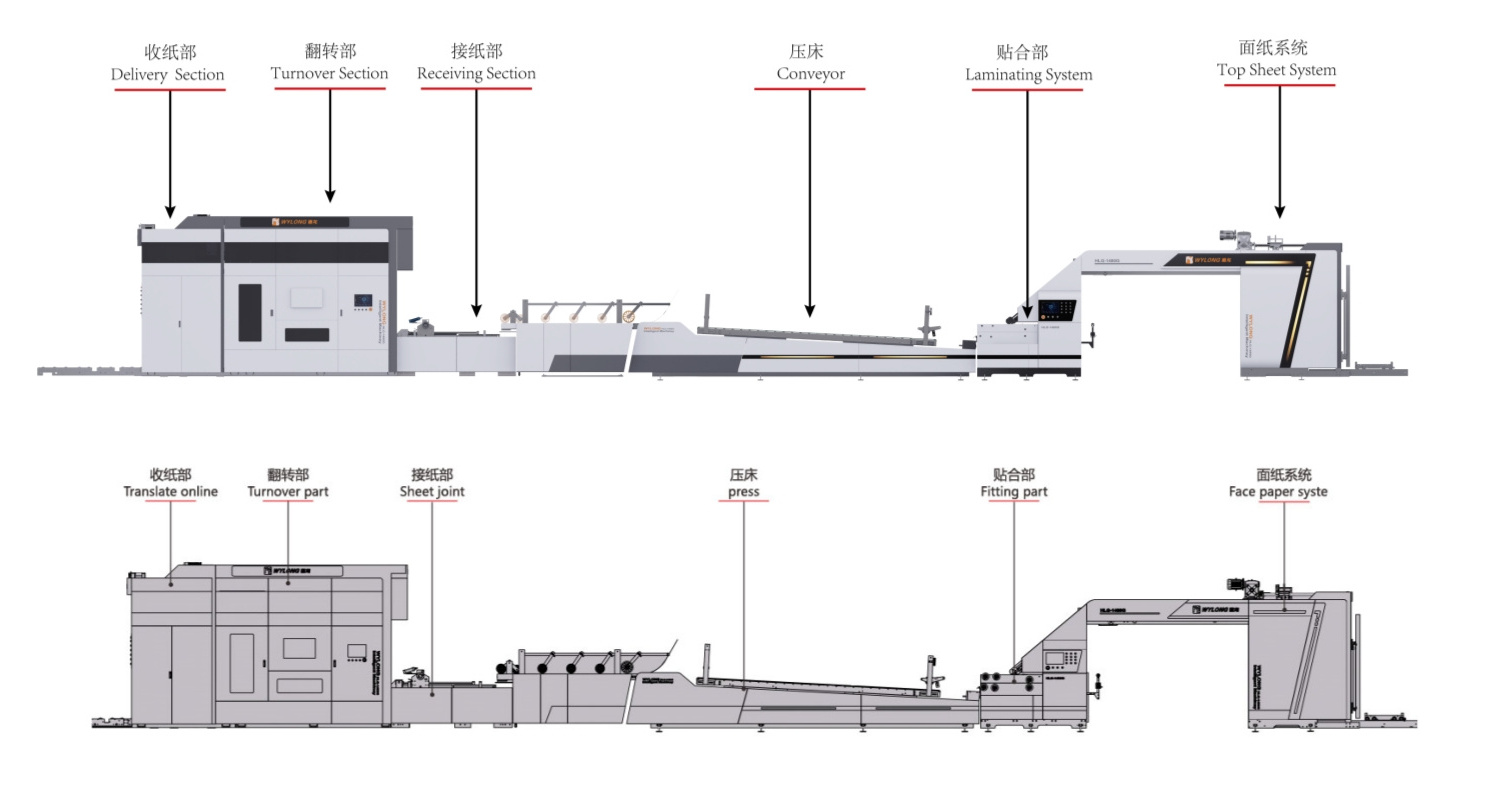

Details Images

Feida system:

Equipped with a high-speed automatic dedicated Feida head, the paper lifting nozzle can freely adjust the paper lifting angle, and the paper feeding nozzle can adjust the paper feeding angle regardless of thick or thin paper, ensuring high-speed and stable paper feeding.

Bottom paper system:

Adopting imported servo motor control system, equipped with Nida suction belt from Japan, variable frequency adjustment of suction force, belt water roller cleaning, patented technology to ensure smooth paper output of corrugated paper and cardboard, and simple operation.

Positioning system:

Utilizing multiple sets of photoelectric sensors to sense the relative position of the backing paper in advance, controlling the servo motors on both sides of the backing paper to perform independent compensation actions, ensuring precise adhesion between the backing paper and the backing paper.

Transmission system:

It adopts imported double tooth Timing belt transmission and is equipped with tensioning device to ensure accurate, stable and low noise transmission.

Electrical system:

designed according to European CE standards, ensuring the stability, high efficiency, and low failure of the entire machine. By combining the human-machine interface with the PLC, various information such as warnings, detected faults, abnormal states, and operating speeds are displayed on the screen at a glance.

Gluing system:

Adopting stainless steel water roller, it will never rust. After fine grinding, the glue amount is adjusted to the minimum to ensure even glue. The lower roller is cleaned with a water roller.

Why Choose Us

We have two Global aftermarket services

locations in

India

and

Mexico

!!

Our machine has a unique skew correction system, so that the paper does not deviate during the transmission process, which is

conducive to post-wound production and improve production efficiency

The corrugated part is widened, which better improves the stability of the machine and is convenient for workers to use and

operate.

The whole machine adopts Yaskawa servo motor imported from Japan, which has higher efficiency and lower failure rate

MAIN FEATURES:

1.The fastest speed is 12000 sheets/hour

2.Fully realize intelligent automation

3.Automatic adjustment of paper specifications

4.Automatic tracking system for bottom paper and top paper

5.The left and right positioning of the bottom paper is rectified in the whole process

6.The whole process of the left and right positioning of the face paper is corrected

7.Intelligent detection of paper length

8.Intelligent fault display alarm system

9.Intelligent glue supply and recovery system

10.Intelligent cleaning water circulation system

11.Backing paper bending and pressing device

12.Bottom paper suction size adjustment device

13.Bottom paper belt automatic cleaning device

14.The most advanced electrical control system

15.shaped pre-stack paper lifting device

16.Anti-glue protection device

17.Facial paper with ball inclined pull

18.Anti-glue protection device

19.Facial paper with ball inclined pull

1.The fastest speed is 12000 sheets/hour

2.Fully realize intelligent automation

3.Automatic adjustment of paper specifications

4.Automatic tracking system for bottom paper and top paper

5.The left and right positioning of the bottom paper is rectified in the whole process

6.The whole process of the left and right positioning of the face paper is corrected

7.Intelligent detection of paper length

8.Intelligent fault display alarm system

9.Intelligent glue supply and recovery system

10.Intelligent cleaning water circulation system

11.Backing paper bending and pressing device

12.Bottom paper suction size adjustment device

13.Bottom paper belt automatic cleaning device

14.The most advanced electrical control system

15.shaped pre-stack paper lifting device

16.Anti-glue protection device

17.Facial paper with ball inclined pull

18.Anti-glue protection device

19.Facial paper with ball inclined pull

Our factory

Exhibition

Certifications

FAQ

1.Who Are We?

5.What Services Can We Provide?

We are based in Zhejiang, China, start from 2004,sell to South America(30.00%),Africa(30.00%),Southeast

Asia(20.00%),South Asia(5.00%),Eastern Asia(5.00%),Eastern Europe(5.00%),North America(5.00%). There are total about 11-50 people in our office.

Asia(20.00%),South Asia(5.00%),Eastern Asia(5.00%),Eastern Europe(5.00%),North America(5.00%). There are total about 11-50 people in our office.

2.How Can We Guarantee Quality?

Always a pre-production sample before mass production; Always final Inspection

before shipment;

before shipment;

3.What Can You Buy From Us?

Automatic Cardboard Laminating Machine,Automatic Flute Laminating Machine,Automatic

Paper box patching Gluing Machine, Automatic folder Gluer,Automatic Die Cutting Machine

Paper box patching Gluing Machine, Automatic folder Gluer,Automatic Die Cutting Machine

4.Why Should You Buy From Us Not From Other Suppliers?

Wylong Machinery Co., Ltd. is a professional corporation specialize in manufacture full complete production line

of Automatic Cardboard Laminating Machine,Automatic Flute Laminating Machine and other industrial machinery with more than 20 years experience.

of Automatic Cardboard Laminating Machine,Automatic Flute Laminating Machine and other industrial machinery with more than 20 years experience.

5.What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment

Type: T/T,L/C; Language Spoken:English

Type: T/T,L/C; Language Spoken:English

Hot Searches