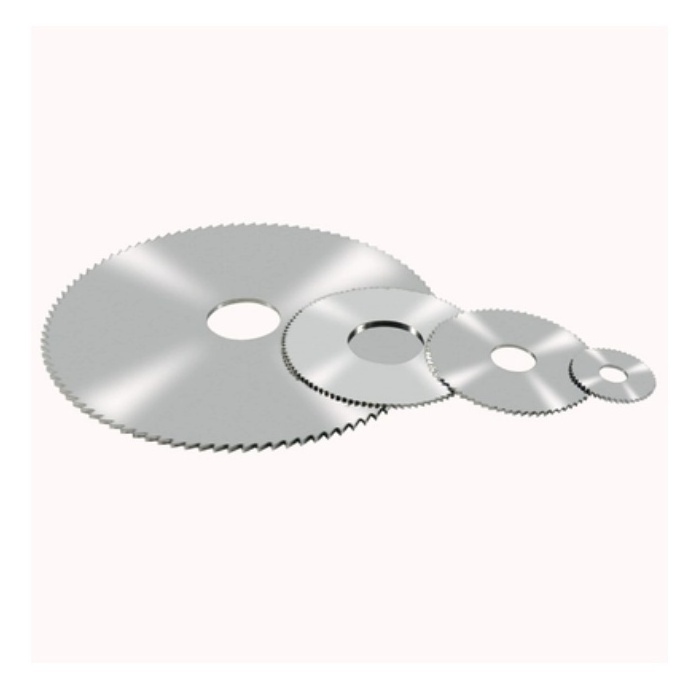

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Blade Width:

-

16mm-250mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AFM

Quick Details

-

Blade Length:

-

0.3mm-5mm

-

Finishing:

-

Ti-coated

-

Size:

-

16mm-250mm

-

Warranty:

-

1 year

-

Blade Width:

-

16mm-250mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AFM

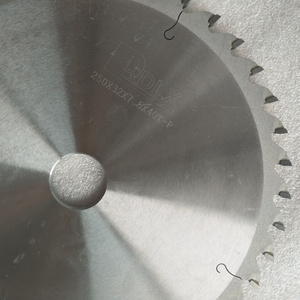

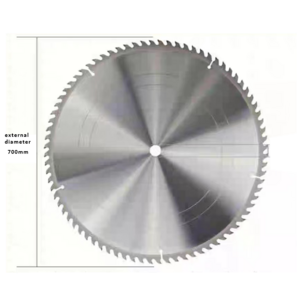

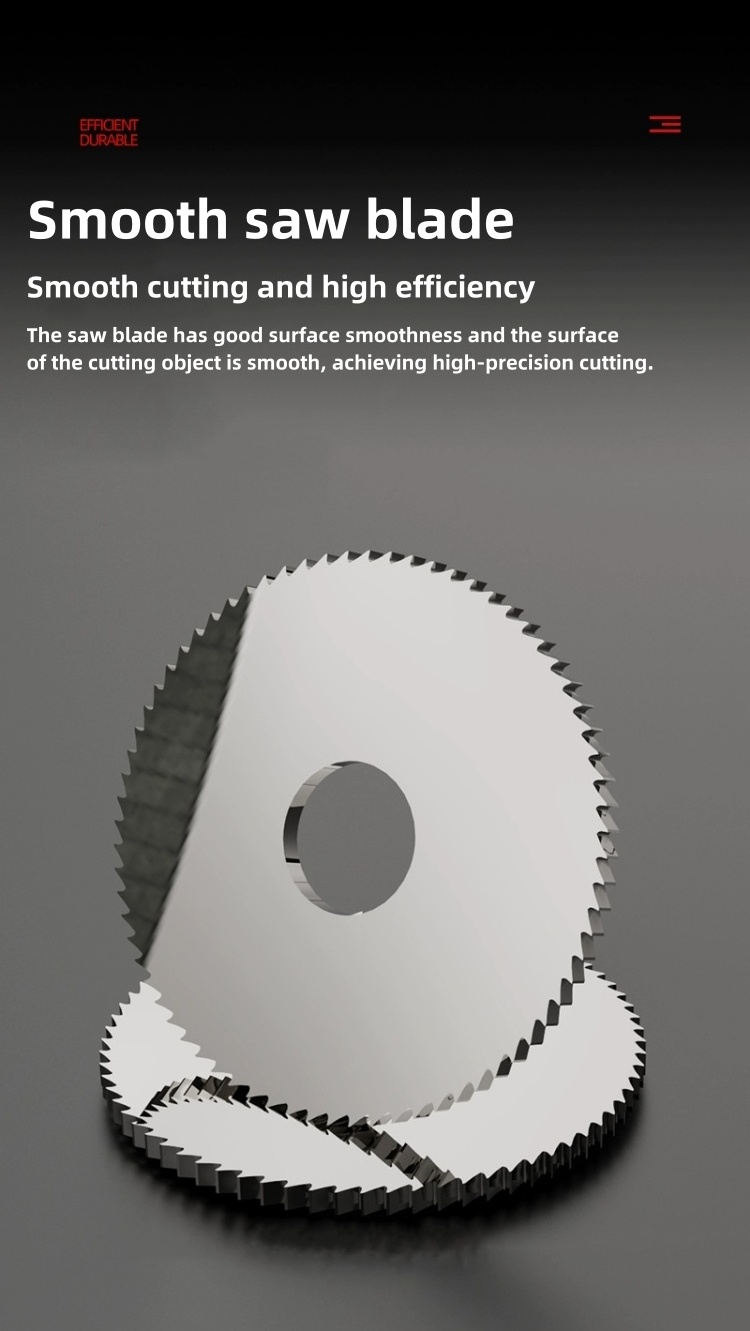

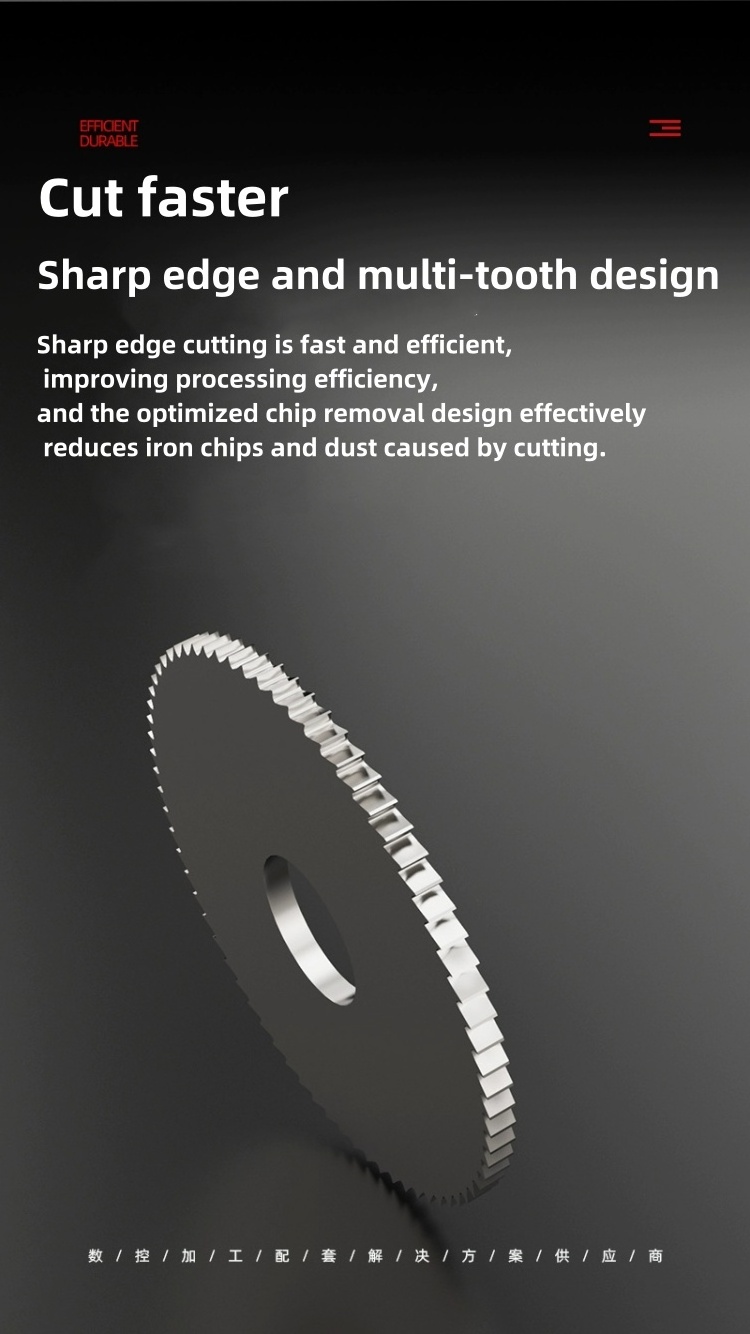

The quality of carbide saw blades and tungsten steel saw blades is closely related to the quality of the processed products. The correct and reasonable selection of tungsten steel saw blades is of great significance to improving product quality, shortening the processing cycle, and reducing processing costs. An alloy using medium-grained and coarse-grained WC has excellent toughness, impact resistance, and thermal shock resistance. It can be widely used in cold forging molds that require impact resistance, as well as crushing blades in environmental protection fields. Among them, the LA80 category is also suitable for the field of warm forging. Generally speaking, the greater the number of teeth, the more edges can be cut per unit time and the better the cutting performance. However, a large number of cutting teeth requires a large amount of cemented carbide. The price of the saw blade is high, but if the saw teeth are too dense, the chip capacity between the teeth becomes smaller, which can easily cause the saw blade to heat up; in addition, if there are too many saw teeth, if the feed rate is not properly matched, the amount of cutting per tooth will be very small, which will aggravate the cutting edge. The friction between the mouth and the workpiece affects the service life of the blade. Usually the tooth spacing is 15-25mm, and a reasonable number of teeth should be selected according to the material being sawed.

| Outter Dia | Thickness | Inner Dia | Teeth number |

| 16 | 0.1-3.0 | 5 | 30 |

| 20 | 0.1-3.1 | 6 | 16/40 |

| 25 | 0.1-3.1 | 6 | 20/45 |

| 30 | 0.1-3.1 | 8 | 24/50 |

| 40 | 0.2-3.1 | 13 | 32/60 |

| 50 | 0.3-3.1 | 16 | 40/65 |

| 60 | 0.3-3.1 | 16 | 45/72 |

| 75 | 0.4-3.1 | 22 | 52/90 |

| 80 | 0.4-3.1 | 22 | 56/100 |

| 90 | 0.4-3.1 | 22 | 64/110 |

| 100 | 0.4-3.1 | 22/27 | 72/120 |

| 110 | 0.5-3.1 | 27 | 80/128 |

| 125 | 0.8-2.0 | 25.4/27 | 80/150 |

| 150 | 0.8-1.0 | 25.4/27 | 100/150 |

| 160 | 0.8-1.0 | 25.4/27 | 108/200 |

| 180 | 0.8-1.0 | 25.4/27 | 108/200 |

| 200 | 1.0 | 27 | 120/250 |

| 250 | 1.2-1.4 | 27/32 | - |

1. Express like DHL,Fedex,UPS,TNT,EMS and so on;

2. By air,nearest port is Shenzhen,China;

3. By sea,nearest port is Shenzhen,China.

1. 100% Inspected Before Shipping Out

2. Free Samples if the value is not too much;

3. Free Shipping if we feel your sincerity;

4. 100% Return if there is quality problem;

5. Fastest Delivery Date;

6. Economy Shipping Cost,unless you choose the fastest shipping way;

7. 24*7 Service

8 Technical Support