- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

800

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JKMF

-

Dimension(L*W*H):

-

1350*850*2200MM

-

Product name:

-

Drip coffee bag packing machine

-

Filling range:

-

5-15g

-

Packing speed:

-

30-40 Bags/min

-

Item:

-

Small Industries

-

Material:

-

Stainless Steel 304

-

Control system:

-

Mitsubishi PLC+English Touch Screen

-

Main Function:

-

Weighing Forming Filling Sealing

-

Optional Devices:

-

Data Printer

-

Advantage:

-

Servo Motor Control

-

Bag style:

-

3-side-seal

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Bags, Film, Foil

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

800

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JKMF

-

Dimension(L*W*H):

-

1350*850*2200MM

-

Product name:

-

Drip coffee bag packing machine

-

Filling range:

-

5-15g

-

Packing speed:

-

30-40 Bags/min

-

Item:

-

Small Industries

-

Material:

-

Stainless Steel 304

-

Control system:

-

Mitsubishi PLC+English Touch Screen

-

Main Function:

-

Weighing Forming Filling Sealing

-

Optional Devices:

-

Data Printer

-

Advantage:

-

Servo Motor Control

-

Bag style:

-

3-side-seal

Ultrasonic Sealing

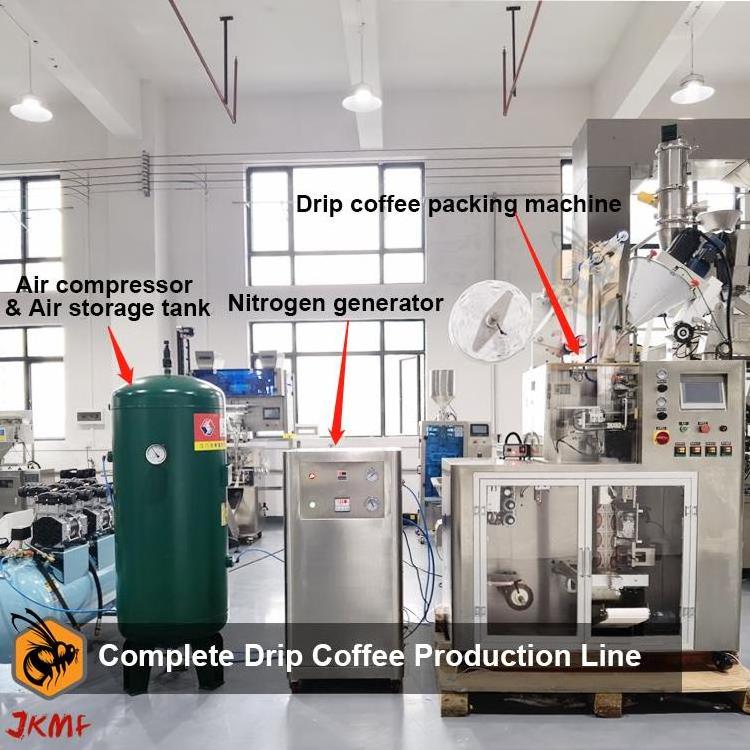

Drip Coffee Bag Making Packing Machine

Products Description

Drip coffee packing machines are widely used in the coffee industry to produce single-serve coffee products. These products are typically sold in sachets or pods and are designed to be convenient and easy to use.

This machines are used to pack ground coffee into individual drip coffee bags that can be used to brew a single cup of coffee. The machine typically works by filling a hopper with ground coffee, which is then measured and dispensed into individual filter bags. The bags are then sealed and packaged for distribution.

Overall, drip coffee packing machines offer a fast, efficient, and cost-effective way to produce high-quality single-serve coffee products. They are an essential tool for coffee manufacturers looking to meet the demands of the modern coffee market.

|

Drip coffee bag packing machine

|

DS-300A

|

|

|

Filling range

|

5~10 g (According to the nature of the product)

|

|

|

Bag size

|

Drip bag:W:45~80 mm,L:50~70 mm

Outer bag:W:75~95 mm,L:80~120 mm |

|

|

Packing speed

|

30~70 bags/min

|

|

|

Voltage

|

220V/380V

|

|

|

Machine power

|

3.5KW

|

|

|

Air pressure

|

0.5MPa-0.75 MPa

|

|

|

Max. gas consumption

|

0.45 m³/m

|

|

|

Machine size

|

1350*850*2200 mm

|

|

|

Machine weight

|

500KG

|

|

Main Features

1. Outer bag sealing controlled by the stepper motor, bag length positioning is accurate and stable.

2. Adopts PID temperature controller for more accurate temperature adjustment.

3. Adopts PLC control system, human-machine interface, it is very easy to operate.

4. All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to

food sanitary standards.

5. Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

6. Optional devices: flat cut device, date printer, easy tear device, etc.

3. Adopts PLC control system, human-machine interface, it is very easy to operate.

4. All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to

food sanitary standards.

5. Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

6. Optional devices: flat cut device, date printer, easy tear device, etc.

Machine Details

The workflow of drip coffee packing machine involves several steps:

Ground coffee is loaded into a hopper, which feeds the coffee into a dosing unit.

The dosing unit measures the precise amount of coffee needed for each bag or pod, and dispenses it into a filter bag.

The filter bag is then sealed to prevent the coffee from spilling out.

The sealed bag is then packaged in a sachet or pod, ready for distribution.

The entire process is automated, with the machine able to produce a large number of coffee bags or pods in a relatively short amount of time.

Vacuum Powder Feeding Device

The vacuum powder feeding device can quickly feed powder or fine particles into the hopper. Realize fully automated production.

Powder Measuring Filling Device

Designed for coffee metering and filling systems that can be controlled by setting the desired grammage on the screen. The measurement accuracy is extremely high, and the error is less than ±1%.

Drip Bag Ultrasonic Sealing Device

The machine is equipped with a high-power ultrasonic device, which can effectively seal the corn fiber and nylon materials to ensure the complete sealing effect of the bag.

Outer Bag Making Device

After the drip bag is sealed and packaged, it can enter the outer bag making device, pack the outer bag in an orderly manner, print the production date, and then output the finished product.

Packaging Sample

The packaging effect is beautiful and the sealing is complete.

More Packaging Type Options

JIKE BEE MACHINERY

presents a comprehensive range of cutting-edge packaging equipment for drip coffee. Our advanced solutions include drip coffee bags, pre-made bags, boxes, and more, ensuring efficiency and consistent quality.

Optimize your drip coffee packaging processes with

JIKE BEE MACHINERY

. Our complete equipment range guarantees efficiency, product presentation, and coffee integrity. Partner with us for success in the competitive drip coffee market.

Contact us to get our professional service to help you start your drip coffee business.

Why Choose Us

JIKE BEE MACHINERY has a professional team to provide customers with various packaging solutions. Fully understanding the needs of customers,engineers design the most suitable solution. We have our own processing and assembly workshop and quality inspection and debugging process to ensure the quality of the machine.

After acceptance by the customer, they are packed in international standard wooden cases and shipped.

We will package the machine's instruction manual and a USB flash drive with machine operation videos together with the machine.

Ensure that you can use the machine as soon as you receive it. If you have something you don't understand, our after-sales team will also help you answer in time.

Ensure that you can use the machine as soon as you receive it. If you have something you don't understand, our after-sales team will also help you answer in time.

Hot Searches