- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Customer's Request

-

Material:

-

Steel

-

Bore sizes of cylinder(mm):

-

40-250mm

-

After Warranty Service:

-

Online Support and Video Technical Support

-

Action type:

-

Double Acting

-

Piston stroke length:

-

320-3000mm

-

Work Temperatur:

-

High Temperature

Quick Details

-

Weight (KG):

-

10

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Hydraulic Cylinder

-

Color:

-

Customer's Request

-

Material:

-

Steel

-

Bore sizes of cylinder(mm):

-

40-250mm

-

After Warranty Service:

-

Online Support and Video Technical Support

-

Action type:

-

Double Acting

-

Piston stroke length:

-

320-3000mm

-

Work Temperatur:

-

High Temperature

Product Overview

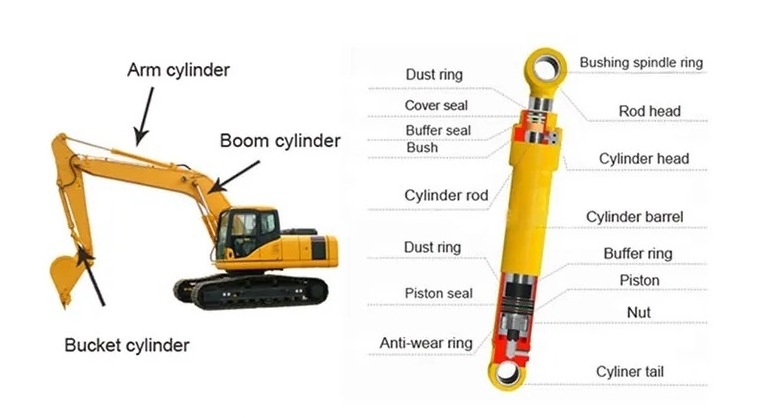

Characteristics and Applications of Engineering Hydraulic Cylinders

Hydraulic Equipment includes Engineering Hydraulic Cylinder, Hydraulic Cylinder for metallurgical equipment, Hydraulic Cylinder For Industry and Thin Hydraulic Cylinder, etc.

Characteristics and Applications of Engineering Hydraulic Cylinders:

DGRHSGx01-Eseries are all double acting single piston rod hydraulic cylinders, which are actuators in the hydraulic system that move in a straight line. It has simple structure, reliable operation, with other characteristics like convenient assembly and disassembly, easy maintenance, and diverse connection methods.

The installation method often adopts earring type. According to the connection method between the cylinder head and the cylinder block, it can be divided into three types: external thread connection, internal key connection, and flange connection.

The engineering hydraulic cylinder mainly uses hydraulic systems for engineering machinery cities, heavy machinery piles, lifting and transportation machinery, and mining machinery combs.

Characteristics and Applications of Engineering Hydraulic Cylinders:

DGRHSGx01-Eseries are all double acting single piston rod hydraulic cylinders, which are actuators in the hydraulic system that move in a straight line. It has simple structure, reliable operation, with other characteristics like convenient assembly and disassembly, easy maintenance, and diverse connection methods.

The installation method often adopts earring type. According to the connection method between the cylinder head and the cylinder block, it can be divided into three types: external thread connection, internal key connection, and flange connection.

The engineering hydraulic cylinder mainly uses hydraulic systems for engineering machinery cities, heavy machinery piles, lifting and transportation machinery, and mining machinery combs.

FEATURES AT A GLANCE

1. Excellent Material Selection Strict selection of materials, professional processing of the inner wall, smooth operation, and long service life

2. Fine workmanship prevents oil leakage, greatly improves service life, saves a lot of maintenance costs, reduces friction

resistance, and provides overall Mechanical efficiency

3. Easy installation It is very convenient to use, without the need for any matching accessories, reducing installation costs

4. Not prone to oil leakage Stable performance: The oil cylinder adopts excellent sealing components, with good sealing effect to maintain normal operation at high speed

5. Strict quality inspection and assurance of quality Each one is made with precision craftsmanship, using excellent standards to process and produce stable structures, saving time and effort, and making it easy to use.

2. Fine workmanship prevents oil leakage, greatly improves service life, saves a lot of maintenance costs, reduces friction

resistance, and provides overall Mechanical efficiency

3. Easy installation It is very convenient to use, without the need for any matching accessories, reducing installation costs

4. Not prone to oil leakage Stable performance: The oil cylinder adopts excellent sealing components, with good sealing effect to maintain normal operation at high speed

5. Strict quality inspection and assurance of quality Each one is made with precision craftsmanship, using excellent standards to process and produce stable structures, saving time and effort, and making it easy to use.

Details

Customized color

Bearing

PRODUCT SPECIFICATIONS

Table 1: Table of Connection Methods for Internal Thread Cylinder Barrel of Piston Rod

|

ltem

|

Connection method

|

Remarks

|

|

1

|

Cylinder bottom earring with bushings

|

|

|

2

|

Cylinder bottom earring with ball joint bearing

|

|

|

3

|

Middle trunnion

|

For cylinder

diameter D≥p80 |

|

4

|

End flange

|

|

|

5

|

Intermediate Flange

|

|

Table 2:Table of Connection Methods For External Thread Cylinder Barrel of Piston Rod

|

ltem

|

Connection method

|

Remarks

|

|

1

|

Cylinder bottom earring with bushings

|

|

|

2

|

Cylinder bottom earring with ball joint bearing

|

|

|

3

|

Middle trunnion

|

For cylinder

diameter D≥Φ80 |

|

4

|

End flange

|

|

|

|

|

|

|

5

|

IntermediateFlange

|

|

Table 3: Table of Buffer Parts

|

ltem

|

Position

|

Remarks

|

|

0

|

Unbuffered

|

Cylinder diameter Φ40,Φ50,Φ63 without buffering

|

|

1

|

Buffered at both ends

|

When the speed ratio is Φ=2, only the bottom end of the cylinder is equipped with a buffer

|

|

2

|

Buffer at the bottom of the cylinder

|

|

|

3

|

Rod end with buffer

|

|

Note:

1. Speed ratio ϕ refers to the ratio of the effective area of the piston to the effective area of the piston rod cavity.

2. The rod diameter size in the speed ratio of 1.46 is the preferred series.

3.In principle, the maximum stroke: ϕ=1.33, S=8D; ϕ=1.46, S=10D; ϕ=2, S=12D.

4. When the user's required S exceeds the maximum stroke specified in the table, it should be resolved through mutual

consultation.

5. The minimum stroke for non hinged shaft and middle flange connections shall be as shown in the table above.

6. 1MPa is approximately equal to 10Kgf/cm2.

Models for your choosing:

1, DGRHSG*01 Series Cylinder Bottom Earrings Internal Thread

2, DGRHSG*01 Series Middle Trunnion Internal Thread

3, DGRHSG*01 Series End Flange Internal Thread

4, DGRHSG*01 Series Intermediate Flange Internal Thread

5, DGRHSG*01 Series Cylinder Bottom Earrings External Thread

6, DGRHSG*01 Series Middle Trunnion External Thread

7, DGRHSG*01 Series End Flange External Thread

8, DGRHSG*01 Series Intermediate Flange External Thread

Below parameters for models 1 and 2, please contact me to get parameters for other models

1. Speed ratio ϕ refers to the ratio of the effective area of the piston to the effective area of the piston rod cavity.

2. The rod diameter size in the speed ratio of 1.46 is the preferred series.

3.In principle, the maximum stroke: ϕ=1.33, S=8D; ϕ=1.46, S=10D; ϕ=2, S=12D.

4. When the user's required S exceeds the maximum stroke specified in the table, it should be resolved through mutual

consultation.

5. The minimum stroke for non hinged shaft and middle flange connections shall be as shown in the table above.

6. 1MPa is approximately equal to 10Kgf/cm2.

Models for your choosing:

1, DGRHSG*01 Series Cylinder Bottom Earrings Internal Thread

2, DGRHSG*01 Series Middle Trunnion Internal Thread

3, DGRHSG*01 Series End Flange Internal Thread

4, DGRHSG*01 Series Intermediate Flange Internal Thread

5, DGRHSG*01 Series Cylinder Bottom Earrings External Thread

6, DGRHSG*01 Series Middle Trunnion External Thread

7, DGRHSG*01 Series End Flange External Thread

8, DGRHSG*01 Series Intermediate Flange External Thread

Below parameters for models 1 and 2, please contact me to get parameters for other models

Application

Hydraulic cylinders are widely used in engineering machinery, molds, automobiles, mines, metallurgy, aviation, ships, agriculture, construction, environmental protection and other industries.

Product packaging

Certifications

Hot Searches