- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YAOKE

-

Model Number:

-

YK-5600

-

Usage:

-

Auto Testing Machine

-

Application:

-

SMT PCB PKG LED Electronics Batte

-

X Ray Tube Voltage:

-

90KV 130KV Optional

-

Loading size:

-

250*250mm

-

Image Process software:

-

Designed in Korea

-

Geometric Mgnigication:

-

15X

-

System Magnification:

-

80X

-

Max tube current:

-

0.5MA

-

Speed of detector:

-

35fps

-

Resolution:

-

1124*1000

Quick Details

-

Warranty:

-

3 years

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YAOKE

-

Model Number:

-

YK-5600

-

Usage:

-

Auto Testing Machine

-

Application:

-

SMT PCB PKG LED Electronics Batte

-

X Ray Tube Voltage:

-

90KV 130KV Optional

-

Loading size:

-

250*250mm

-

Image Process software:

-

Designed in Korea

-

Geometric Mgnigication:

-

15X

-

System Magnification:

-

80X

-

Max tube current:

-

0.5MA

-

Speed of detector:

-

35fps

-

Resolution:

-

1124*1000

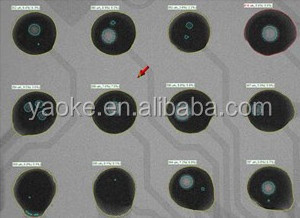

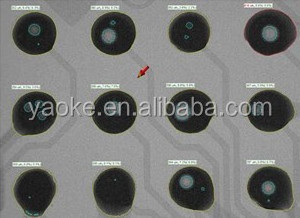

machinery x ray x-ray inspection systems X Ray machine test for welding

Product Application

X-ray high resolution detector adopt high resolution enhanced screen and sealed micro x ray tube combinated structure,to do detect by non- destructive x ray detect,to observe the clear image real -timely.In addition,powerful software measurement capability greatly improve the detect efficiency.Besides, it make detect easily and fast by install CNC components

Full digital x ray detector adopt digital panel detector and x ray integrated digital image interception technology.

Applications:

BGA , CSP , LED , Flip Chip , Semiconductor, Battery Industry , Small Metal Casting, Electronic Connector Module,

Aerospace Components , Photovoltaic Industry, Other Special Industries.

Full Automatic BGA Testing Procedures

1. A simple mouse click programming without the need for operator intervention on the component can detects each BGA automatically.

2. Automatic BGA test, accurately check the bridge, Welding, cold welding and void ratio of BGA.

3. Automatic BGA test repeatable test results in order to process control

4. The test results will be displayed on the screen and can be output to Excel to facilitate review and archiving

CNC Programming

1.A simple mouse clicks operation write test procedures

2.The stage can be X, Y director positioning; X-ray tube and detector Z positioning.

3.Software setting voltage and current

4.Image settings: brightness, contrast, auto gain and exposure

5.The user can set the program switch pause time

6.Anti-collision system can meet the maximum tilt and observe objects

Main Features

1).Defects below 5mm can be detected

2).Convenient to maintain,long operating life

3).Easy to operate,reduce operate training

4).Suitable for mass inspection

5).Semi automatic qualified / unqualified product inspection

6).The repeatability of the detection is high

7).A large number of samples of various sizes can be accommodated

8).Allow a unique view of the sample

9).80KV 10MicroX-RAYclosed tube

10).Checking program that can be programmed

11).250×250MM Stage

12).It's 30 degrees, tilting

Warranty & Service

1. One year warranty service after the product was sold.

2. In the warranty period, users operate according to instruction but meet problems, our company will maintain free of charge.

3. Beyond the warranty period, product problems can also be solved by our company, but charge component cost and maintenance cost properly.

4. Please read the product manual carefully before using this product. Operating the product strictly according to the operation method.

5. Users encounter problems when using our products , pls contact us by telephone or email, we will be ready to provide consulting, maintenance and other services immediately. Digital Martindale Abrasion and Pilling Testers

1)inside is covered with plastic film before we put them into the plywood ctns, which has good transparency,impact resistance,tasteless and prevent moisture corrosion.

2)outside is strong plywood ctns and accord with export standards.

3)we can ship testing equipments according to customer request.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Q1.Are you a manufacturer or a trading company ?

A: We are a professional manufacturer of test instruments. And we have our own subsidiary company for trading. All the import and export business will be handled by our own trading company.

Q2.Where is your factory located ? How can I visit there ?

A: Our factory is located in Dongguan City, Guangdong Province, about 50km by bus from Shenzhen Airport.

Q3.What’s the price of your test instruments?

A: Please contact us via trademanager or email, we will send you detailed quotation.

Q4.How to support me if i don't know how to use it?

A: Free training within the warranty by tel and mail or skype. And we have professional operation manual and operation video. We also can let our technician to customer’s company to provide training and support if customer request.

Q5. If machines wearing parts need changing, what should we do?

A:We can offer the wearing parts all the time, and offer video to show how to change it.

Q6. What's the payment terms if we want to buy the machines?

A: by T/T,

Dongguan Yaoke Instrument Equipment Co.,Ltd is specialize in rubber and plastic testing machine over 10 years,With our advanced technologies and best customer service, Our product has exported to more than 100 countries and regions,which win favorable comments from customers worldwide.

Our production line have turning machine,griding machine,milling machine,CNC machining center and sheet metal bending machine,design department has 5 people special for design and research new product.With these advantages,we can control product quality from source.

If you have any inquiry or concern,Sales and after service department will reply you within 24 hours..

We can produce different size according to your parameter requirement. and we allow proper discount according to the quantity you order,If you have any questions and needs you can contact us at any time.