- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, all sizes can be done

-

Place of Origin:

-

China

-

Marketing Type:

-

High-end block molds

-

Weight (KG):

-

850 kg

-

Mould Life 1:

-

80000-100000 times

-

Mould Life 2:

-

100000-120000 times

-

Mould material 1:

-

16# management steel

-

Mould material 2:

-

Alloy structural steel

-

HS code:

-

848060

-

Mold shoe processing way:

-

Wire cutting by CNC machine

-

Mold surface strength:

-

HRC62-HRC68

-

Size:

-

Cusomized

-

Advantage:

-

Rich Experience

-

Lead time:

-

25-45 Days

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

Other, 10000 times

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, all sizes can be done

-

Place of Origin:

-

China

-

Marketing Type:

-

High-end block molds

-

Weight (KG):

-

850 kg

-

Mould Life 1:

-

80000-100000 times

-

Mould Life 2:

-

100000-120000 times

-

Mould material 1:

-

16# management steel

-

Mould material 2:

-

Alloy structural steel

-

HS code:

-

848060

-

Mold shoe processing way:

-

Wire cutting by CNC machine

-

Mold surface strength:

-

HRC62-HRC68

-

Size:

-

Cusomized

-

Advantage:

-

Rich Experience

-

Lead time:

-

25-45 Days

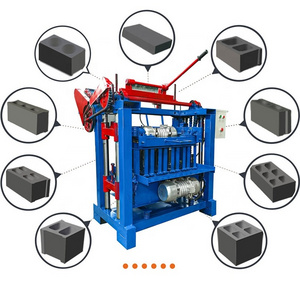

QT6-15 concrete interlock block making machine:

Main technical data of QT6-15 concrete interlock block making machine

| Model |

QT6-15 concrete interlock block making machine

|

| Vibration frequency | 380-4500 times/sub |

| Conversion parameter | 0-60Hz |

| Molding cycle | 15-25s |

| Power | 34.4KW |

| Weight | 12T |

| Pallet dimension | 980*680(mm) pallet |

| Installation dimension | 9450*3300*2700(mm) |

Molding capacity of QT6-15 concrete interlock block making machine

| Hollow block | 6pcs/mould (390*190*190), 11000pcs/day (8hours) |

| Cellular block | 15pcs/mould (240*115*90), 28000pcs/day (8hours) |

| Environmental protection block | 21pcs/mould (200*100*60), 30000pcs/day (8hours) |

| Standard block | 30pcs/mould (238*115*51), 57000pcs/day (8hours) |

2. A floor area of 3500 to 4000 m2 is needed for this production line.

3. Our simple brick production line is suitable for customers who want to start Businesses.

4. Only little investment is needed to yield quick profits. Besides, production Site is alterable based on raw material distribution and places to save material freight.

5. This simple brick production line manufactures standard bricks, perforated Bricks, hollow bricks, and more.

6. Our simple brick production line can be vigorously developed in peripheral Countries and towns of local cities.

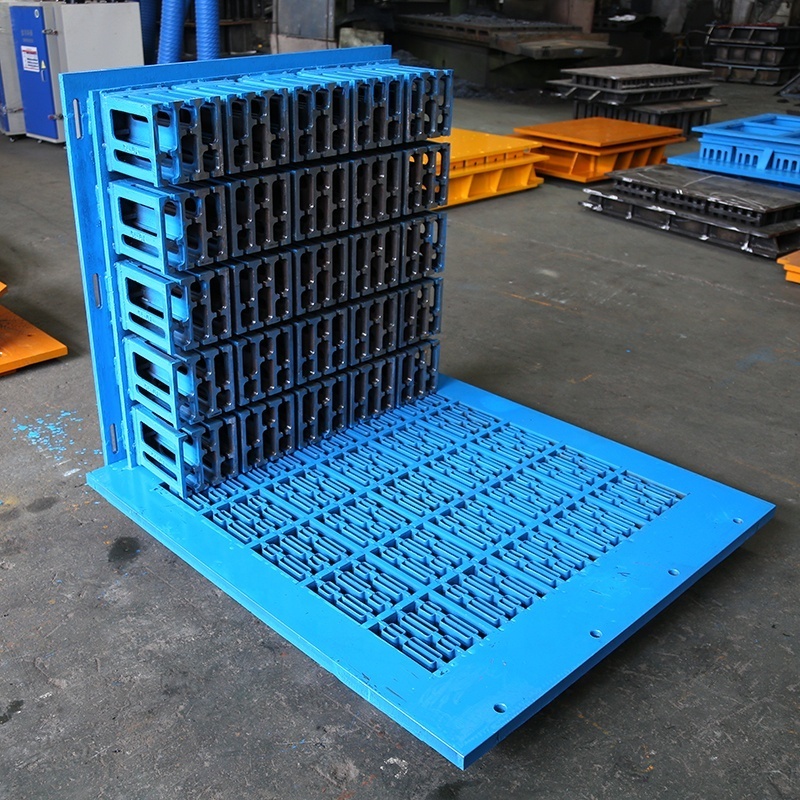

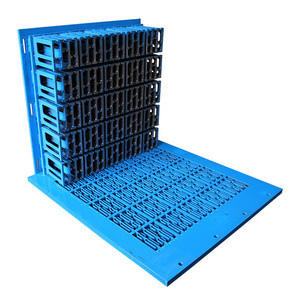

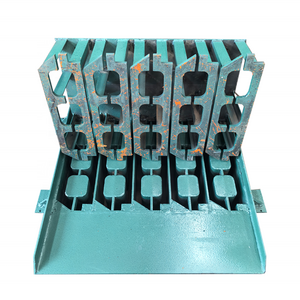

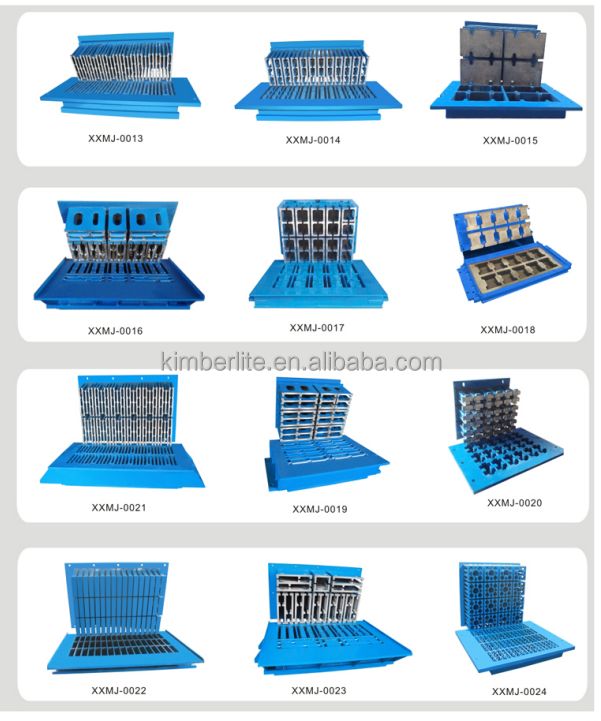

Mould

1, Mould frame are made of 55# Manganese steel, and tamper head is made of 16# manganese steel.

2, Mould frame is made with inlaid structure, and mould are processed via the procedures of carburizing, nitriding and we guarantee the strength of mould core could be HRC33 and mould surface could be HRC61.

3, The lifespan of mould is around 80-100 thousands times.

Color Face System:

Pigment Feeder (feeding the color face material)

When the block machine is equipped with color face material feeding device, it could make various color face bricks, through-body Environmental protection bricks, road curb rocks, hydraulic blocks and SOD bricks etc.

Mixing & Batching System:

The system consists of cement silo, cement scale, screw conveyor, automatic batching machine, aggregate mixer and pigment mixer. The main electrical control components are famous brands to guarantee stable and reliable performance. Separated from the forming system, it is more convenient for users' selection.

PLC Control System:

PLC controls each production procedures with operator panel Review or Mitsubishi programming both in English and Chinese.

Both automatic and manual operation modes are designed on panel. Manual operation is advised to use when machine debugging or malfunction analysis.

All electrical components are famous brand of China and Germany such as: Simens & Wohner, Japan Mitsubishi & Omron, France Schneider, Delta etc.

Auto Block Stacker:

According to the different type of bricks, the finished products will be moved from the discharge transmitter and pilled up automatically 3 to 8 layers by the elevating conveyor, and carried to the maintaining place by the fork lifter truck. It could reduce labor and ground.

JS500 and JS750 Concrete Mixer adopts dual horizontal shafts forced mixing mode.

Automatic Batching System:

Model PL1200 / PL800 automatic batching machine is used to measure aggregate via sensor. It is formed by storage hopper, weighing system, supplying material system, electric control system and two-hopper configuration as its basic form.

The machine is firm and durable as the main body is made of section steel and the hopper is made of welding steel plate. The feeding direction and discharging opening can be adjusted according to actual condition.

|

Model |

JS500 |

JS750 |

|

|

Charging Capacity |

800L |

1200L |

|

|

Discharging Capacity |

500L |

750L |

|

|

Productivity |

≥25m 3 /h |

≥35m 3 /h |

|

|

Maximum Size of Aggregate |

80/60(mm)

|

80/60(mm)

|

|

|

Mixing Blades |

|

35r/min |

30.5r/min |

|

Amount |

2*7 |

2*7 |

|

|

Mixing Electric Motor |

Type |

Y180M-4 |

Y220L-4-4 |

|

Power |

18.5KW |

30KW |

|

|

Hosting Electric Motor |

Type |

YEZ132S-4-B5 |

YEZ132M-4-B5 |

|

Power |

5.5KW |

7.5KW |

|

|

Water Pump |

Type |

50DWB20-8A |

65JDB-5-1.1 |

|

Power |

0.75KW |

1.1KW |

|

|

Discharging Height |

1500mm ,2700mm,3800mm |

1600mm ,2700mm,3800mm |

|

|

Outline Size(L*W*H) |

WorkingState |

4486x3030x5280mm |

5980x2300x6260mm |

|

Transporting State |

3030x2300x2800mm |

4195x2300x2800mm |

|

|

Total Weight |

4000Kg |

6800Kg |

|

Batching Machine and Mixer:

Base concrete brick making production line at buyer's place: