- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Conformal Coating

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KEWEI

-

Model Number:

-

KEWEI-70

-

Type:

-

Conformal Coating, Liquid Coating

-

Product name:

-

Conformal Coating

-

Material:

-

Acrylic

-

Viscosity(25℃, CPS):

-

15

-

Shelf life:

-

6~12 Months

-

Color:

-

Transparent/Light yellow

-

Solid Content (%):

-

30

-

Temperature Range ℃:

-

-70~120

-

Application:

-

SMD/SMT/PCB/Electronics

-

MOQ:

-

100L

Quick Details

-

CAS No.:

-

25035-69-2

-

Other Names:

-

Acrylic

-

MF:

-

C16H26O6

-

EINECS No.:

-

Conformal Coating

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KEWEI

-

Model Number:

-

KEWEI-70

-

Type:

-

Conformal Coating, Liquid Coating

-

Product name:

-

Conformal Coating

-

Material:

-

Acrylic

-

Viscosity(25℃, CPS):

-

15

-

Shelf life:

-

6~12 Months

-

Color:

-

Transparent/Light yellow

-

Solid Content (%):

-

30

-

Temperature Range ℃:

-

-70~120

-

Application:

-

SMD/SMT/PCB/Electronics

-

MOQ:

-

100L

Product Description

INTRODUCTION

Conformal coating is a specially formulated coating used to protect circuit boards and related equipment from environmental erosion, thereby improving and extending their service life and ensuring the safety and reliability of use. Conformal coating has good high temperature resistance; after curing, it forms a transparent protective film, which has excellent insulation, moisture-proof, leakage-proof, shock-proof, dust-proof, anti-corrosion, anti-aging, corona resistance and other properties.

Conformal coatings are used in high-tech fields, electronics industry, military industry, wiring lines, etc. Conformal coatings can enable manufacturers to improve product quality and reduce expensive protection period failure costs.

|

Conformal Coating KEWEI-70

|

|

|

|

KEWEI-70 is a kind of single-component acrylic transparent protecting paint, which can form a glazing and stretchable protecting foam on various of printed circuit boards. It can prevent the corrosion of weak acid, alkali, alcohol, mildew, salt fog, thermal stress, ultraviolet radiation, humidity and insect. This product is high-temperature resistant and will not drop on heat, and tin can be welded directly on the protecting foam. It can conform to the requirements of EU ROHS Directive completely.

|

|

|

|

Before Curing

|

Color: Transparent

Color:Transparent

Density (g/cm3):0.75±0.02

Viscosity (25℃, CPS): 15

Surface dry time: 10 Min

Solid content: 20% Flash point:10°C Boiling point:80 °C |

|

|

After Curing

|

Hardness(Shore D): 60Temperature Range ℃: -70~120

Elongation Rate at break (%):150

Shear Strength (MPa):1.3±0.2

Volume Resistivity (Ω·cm):≥ 1.0×10^14

Dielectric Strength (kV/·mm): ≥21

|

|

INSTRUCTIONS

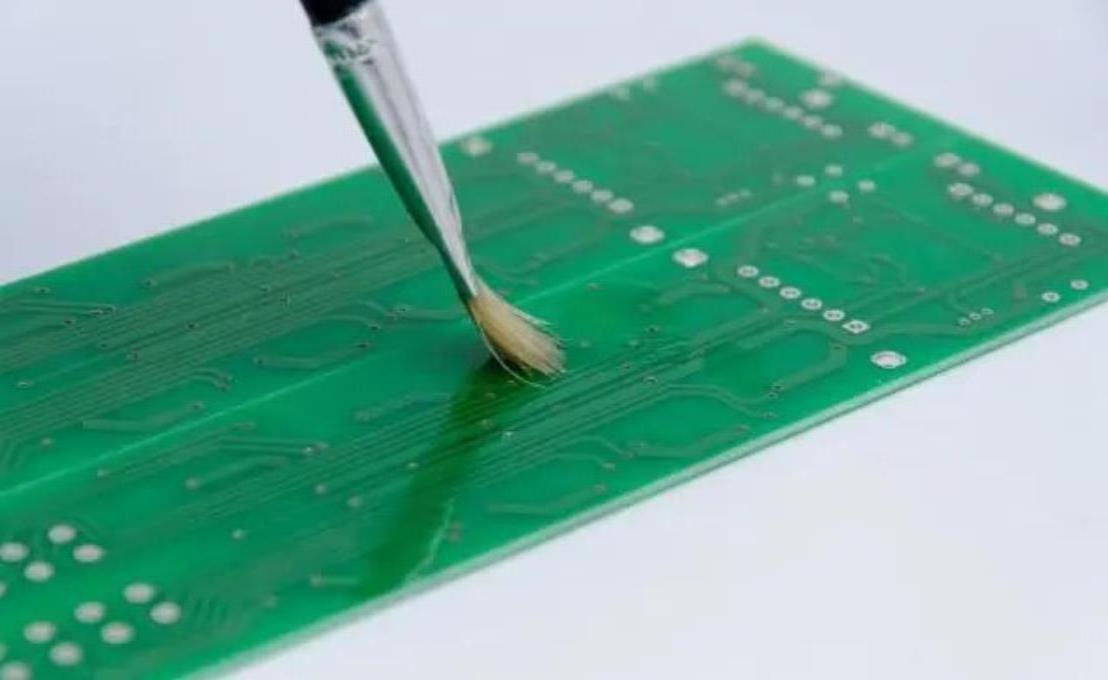

Brushing

The brushing area should be larger than the area occupied by the device to ensure full coverage of the device and pad. Lay the board flat when brushing. There should be no drips after brushing, and the brushing should be smooth, and there should be no bare leaks, and it should be placed on the bracket after brushing.

Dipping

Put the diluted paint into the immersion bucket. The circuit board components should be immersed in the paint tank vertically. The connectors should not be immersed unless they are carefully covered. The circuit board or components should not be immersed too fast to avoid air bubbles.

spraying

Adjust the spray gun and pressure, and put the diluted paint into the watering can. The nozzle of the spray gun needs to be sprayed smoothly. In order to ensure that the paint can pass through the bottom of the component well, the spray should be sprayed smoothly from all angles.

Company information

Shenzhen Kewei Tin Industry Co., Ltd was built up since 2006. For over 13 Years' development, with advanced technical strength and complete product range, we are a mature solder product manufacturing enterprise and getting into the second biggest manufacturer in China.

We have many automation equipment and high accuracy metal spectrum testing equipment, perfect management system and a number of senior technology R&D engineers. We provide high-quality solder products and related professional technical service for the modern high-tech electronics manufacturers and companies.

We have many automation equipment and high accuracy metal spectrum testing equipment, perfect management system and a number of senior technology R&D engineers. We provide high-quality solder products and related professional technical service for the modern high-tech electronics manufacturers and companies.

Hot Searches