- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.09%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

85%-99%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SISIC/RSIC

-

Brand Name:

-

Robert

-

Size:

-

Customers' Requirement

-

Sample:

-

Available

-

Application:

-

Kiln Shelves

-

Bulk Density:

-

>3.02(g/cm3)

-

Bending Strength:

-

250-280Mpa

-

Modulus of Elastictiy:

-

300-330Gpa

-

Thermal Conductivity:

-

45(1200℃)(W/m.k)

-

Color:

-

Black/Grey

-

Shipping Port:

-

Qingdao/Tianjin/Shanghai

-

Max Temperature of Application:

-

≤1380℃

Quick Details

-

SiO2 Content (%):

-

0.25%-10%

-

Al2O3 Content (%):

-

<0.05%

-

MgO Content (%):

-

0.01%

-

CaO Content (%):

-

0.09%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

85%-99%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SISIC/RSIC

-

Brand Name:

-

Robert

-

Size:

-

Customers' Requirement

-

Sample:

-

Available

-

Application:

-

Kiln Shelves

-

Bulk Density:

-

>3.02(g/cm3)

-

Bending Strength:

-

250-280Mpa

-

Modulus of Elastictiy:

-

300-330Gpa

-

Thermal Conductivity:

-

45(1200℃)(W/m.k)

-

Color:

-

Black/Grey

-

Shipping Port:

-

Qingdao/Tianjin/Shanghai

-

Max Temperature of Application:

-

≤1380℃

Product Description

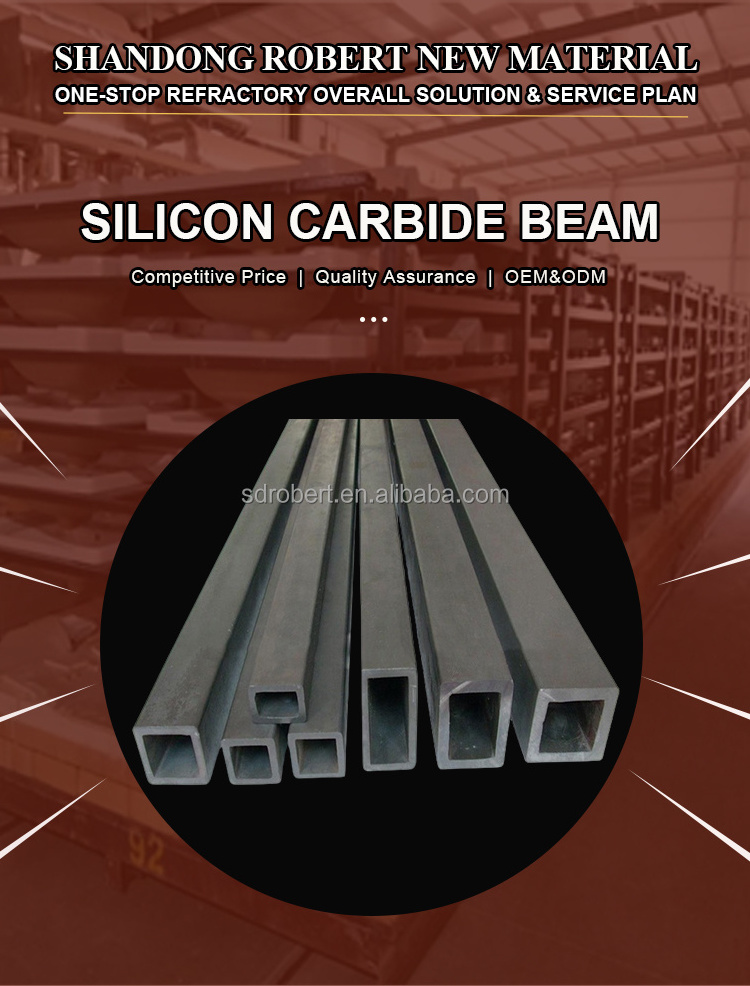

Silicon carbide beams

have excellent high-temperature bearing capacity, good dimensional stability, and anti-oxidation and

anti-corrosion capabilities. They have a long service life (below 1380 degrees) and will not break suddenly, will not get dirty or

slag off, and will not pollute the fired products. They are suitable for load-bearing structural beams in tunnel kilns, shuttle

kilns, double-layer roller kilns and other industrial kilns.

Features

1. High abrasion resistance

2. High energy efficiency

3. No deformation under high temperature

4. Maximum temperature tolerance 1650 degree celsius

5. Corrosion resistance

6. High bending strength under 1100 degree: 100-120MPA

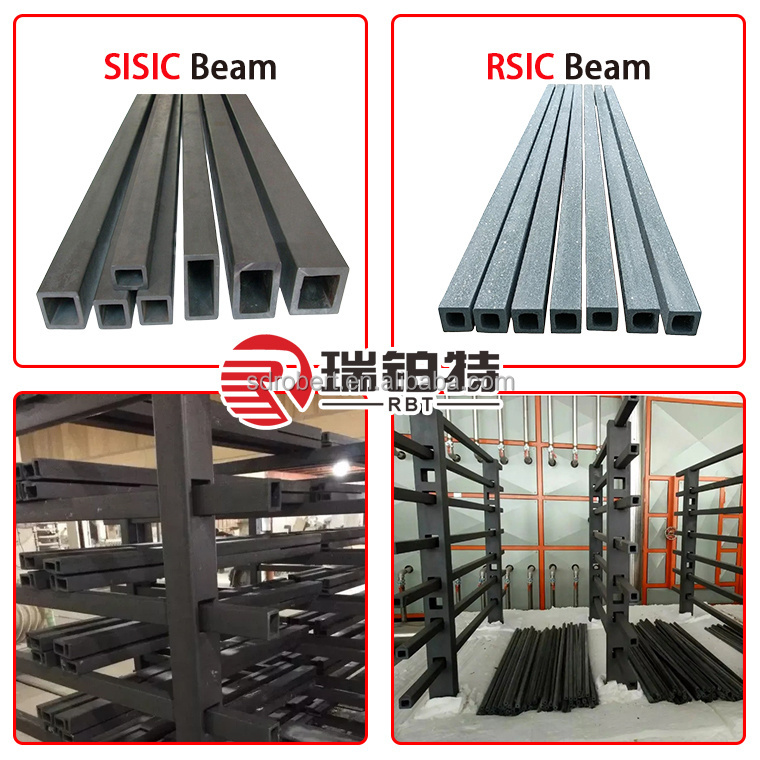

Details Images

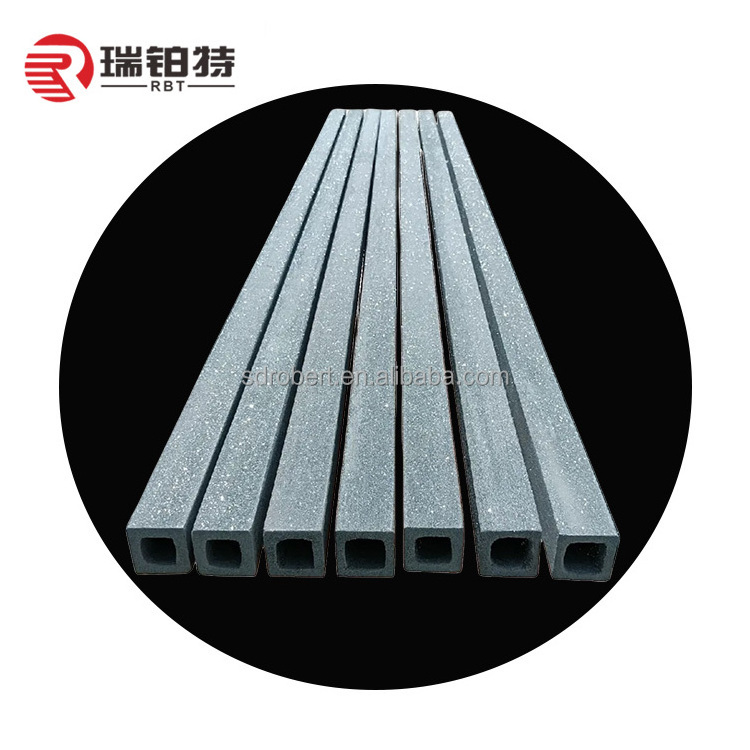

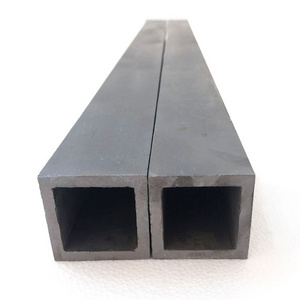

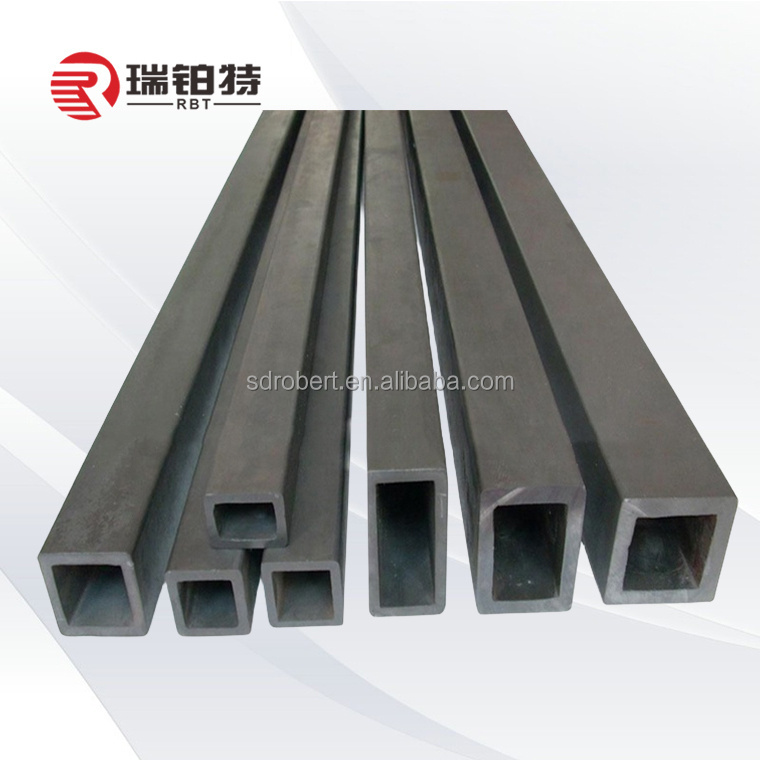

SISIC Beam

RSIC

Beam

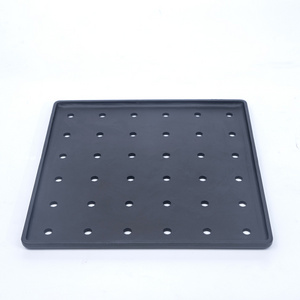

SiC Beam With Holes

Silicon Carbide Beam

Kiln Shelves

Product Index

|

Reactive Sintering Silicon Carbide Beam

|

|

|

||

|

Item

|

Unit

|

Data

|

||

|

Max Temperature of Application

|

℃

|

≤1380

|

||

|

Density

|

g/cm3

|

>3.02

|

||

|

Open Porosity

|

%

|

≤0.1

|

||

|

Bending Strength

|

Mpa

|

250(20℃); 280(1200℃)

|

||

|

Modulus of Elastictiy

|

Gpa

|

330(20℃); 300(1200℃)

|

||

|

Thermal Conductivity

|

W/m.k

|

45(1200℃)

|

||

|

Thermal Expansion Coefficient

|

K

-1

*10

-6

|

4.5

|

||

|

Moh's Hardness

|

|

9.15

|

||

|

Acid Alkaline-Proof

|

|

Excellent

|

||

|

Bearing Capacity of RBSiC(SiSiC) Beams

|

|

|

|

|

|

|

||||||

|

Size of Section

(mm)

|

|

Wall Thickness

(mm)

|

Concentrated Loading(kg.m/L)

|

|

Uniformly Distributed Loading(kg.m/L)

|

|

||||||

|

B Side

|

H Side

|

|

W Side

|

H Side

|

W Side

|

H Side

|

||||||

|

30

|

30

|

5

|

74

|

74

|

147

|

147

|

||||||

|

30

|

40

|

5

|

117

|

95

|

235

|

190

|

||||||

|

40

|

40

|

6

|

149

|

149

|

298

|

298

|

||||||

|

50

|

50

|

6

|

283

|

283

|

567

|

567

|

||||||

|

50

|

60

|

6

|

374

|

331

|

748

|

662

|

||||||

|

50

|

70

|

6

|

473

|

379

|

946

|

757

|

||||||

|

60

|

60

|

7

|

481

|

481

|

962

|

962

|

||||||

|

80

|

80

|

7

|

935

|

935

|

1869

|

1869

|

||||||

|

100

|

100

|

8

|

1708

|

1708

|

3416

|

3416

|

||||||

|

110

|

110

|

10

|

2498

|

2498

|

4997

|

4997

|

||||||

Applications

Package&Warehouse

Hot Searches