1. Lining, insulation and repair for furnaces, kilns, ovens, boilers;

2. Insulation for power plant, turbine, thermal reactor, generator and nuclear applications;

3. Expansion joint seal and insulation;

4. Wrapping and insulation for high temperature pipes or metal casting;

5. Fire protective insulation and lining Other high temperature seal, gasket, insulation or protection.

- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.08-0.12Mpa

-

Density (kg/m³ ):

-

128

-

Length:

-

Customers Requested

-

Working Temperature:

-

1000-1350℃

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.055-0.180(W.k.m.)

-

Model Number:

-

COM/STD/HC/HA/HZ/HAZ

-

Brand Name:

-

Robert

-

Place of Origin:

-

Shandong, China

-

Color:

-

Pure White

-

HS Code:

-

68061090

-

Classification Temperature:

-

1050℃-1430℃

-

Slag Content:

-

12%-20%

-

Bulk Density:

-

96~160(kg/m3)

-

Al2O3:

-

39%-44%

-

Fe2O3:

-

0.2%-1.0%

-

Al2O3+SiO2:

-

84%-99%

-

Regular Size(mm):

-

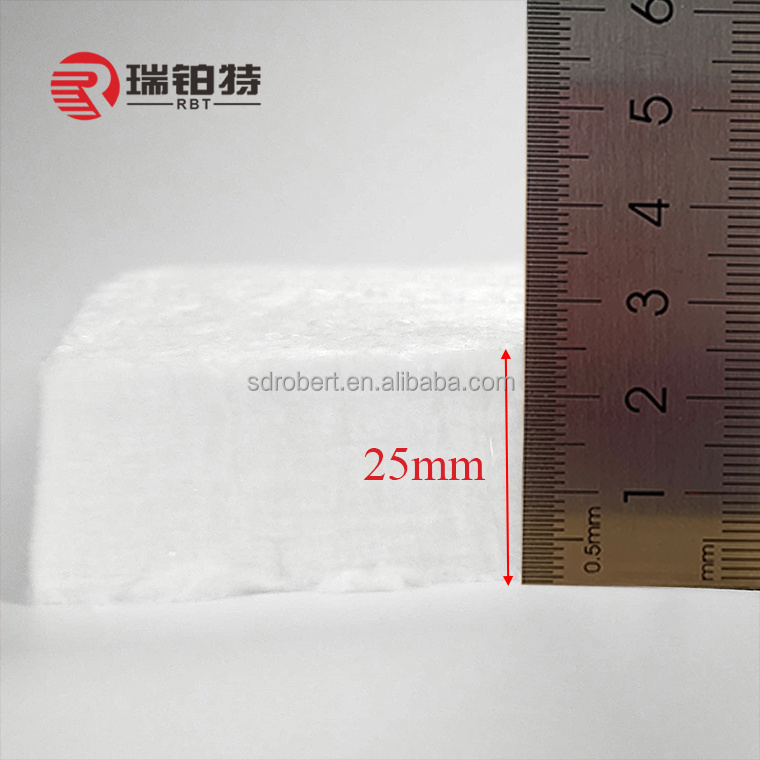

14400*610*12.5 3600*610*50 7200*610*25

-

Package:

-

Woven Bag/Carton

Quick Details

-

Thickness:

-

6-50mm

-

Width:

-

Customers Requested

-

Chemical Composition:

-

AL2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.08-0.12Mpa

-

Density (kg/m³ ):

-

128

-

Length:

-

Customers Requested

-

Working Temperature:

-

1000-1350℃

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.055-0.180(W.k.m.)

-

Model Number:

-

COM/STD/HC/HA/HZ/HAZ

-

Brand Name:

-

Robert

-

Place of Origin:

-

Shandong, China

-

Color:

-

Pure White

-

HS Code:

-

68061090

-

Classification Temperature:

-

1050℃-1430℃

-

Slag Content:

-

12%-20%

-

Bulk Density:

-

96~160(kg/m3)

-

Al2O3:

-

39%-44%

-

Fe2O3:

-

0.2%-1.0%

-

Al2O3+SiO2:

-

84%-99%

-

Regular Size(mm):

-

14400*610*12.5 3600*610*50 7200*610*25

-

Package:

-

Woven Bag/Carton

Product Description

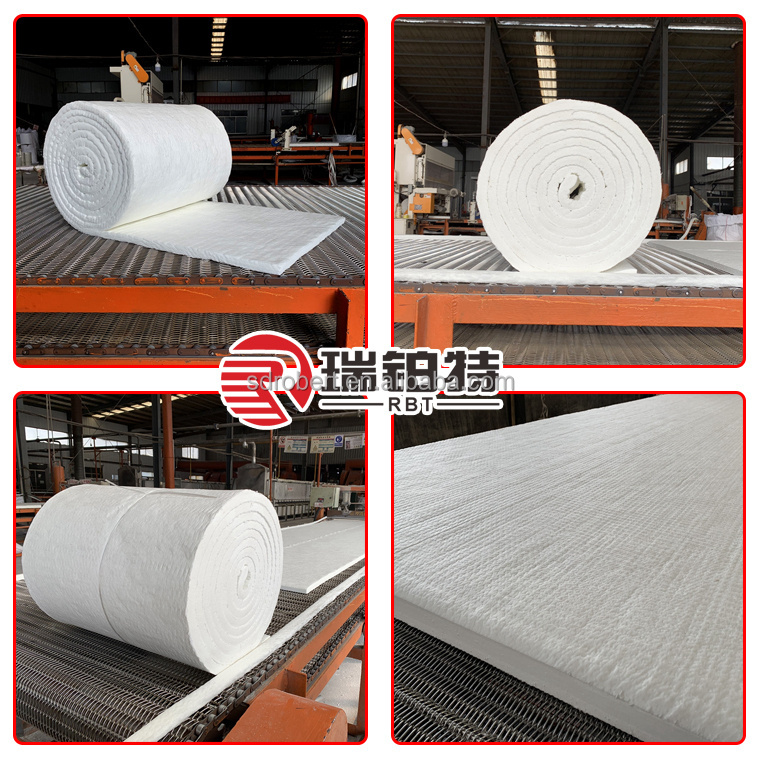

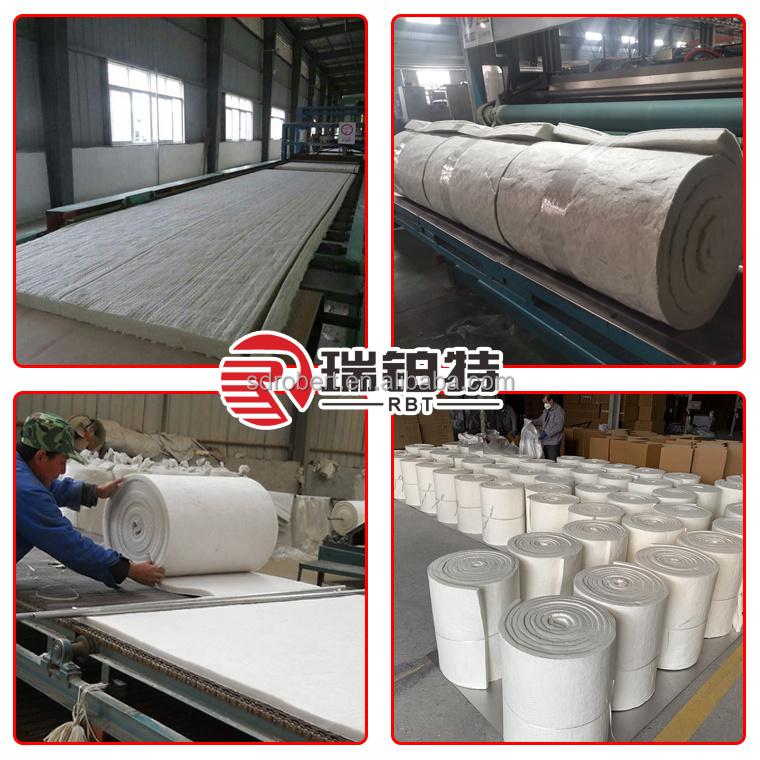

The ceramic fiber blankets are white and regular size. It integrates the functions of refractory, heat insulation and heat preservation and does not contain any binder.

Features

1. Low thermal capacity 2. Low thermal conductivity

3. Excellent chemical stability 4. Excellent thermal shock resistance

5. Excellent tensile strength 6. Excellent sound absorption

7. Heat insulation performance

3. Excellent chemical stability 4. Excellent thermal shock resistance

5. Excellent tensile strength 6. Excellent sound absorption

7. Heat insulation performance

Details Images

|

Regular Size(mm)

|

14400*610*12.5 3600*610*50 7200*610*25

|

|

Model

|

COM/STD/HC/HA/HZ/HAZ

|

Aluminum Foil Faced Ceramic Fiber Blanket

1. Fireproof Insulation:

High-quality ceramic fiber insulation blanket backed with strong 50-micron thick Aluminum Foil is a high heat resistant non-combustible blanket, rated up to 2400° F (on the side of the ceramic wool of blanket, not on the side of the aluminum foil attached) and measures 1/2-inch X 24 inches X 6.2 ft. in size, Density 6lbs.

2. Strong and Durable: This non-combustible blanket has high tensile strength and thermal shock resistance which allows it to maintain its soft structure without shrinkage when used within the recommended range of temperature.

3. Lightweight & Flexible: Being lightweight and flexible these blankets are extremely easy to install & work with. Moreover, they are easy to cut in the desired shape as well according to the need, making their installation effortless and hassle-free.

4. Enhanced Protection: These strong and durable ceramic fiber blankets with aluminum foil attached on one side are meant to provide surface protection to the blanket from external damage. Thus providing superior insulation value and protection to your parts/components or surface.

2. Strong and Durable: This non-combustible blanket has high tensile strength and thermal shock resistance which allows it to maintain its soft structure without shrinkage when used within the recommended range of temperature.

3. Lightweight & Flexible: Being lightweight and flexible these blankets are extremely easy to install & work with. Moreover, they are easy to cut in the desired shape as well according to the need, making their installation effortless and hassle-free.

4. Enhanced Protection: These strong and durable ceramic fiber blankets with aluminum foil attached on one side are meant to provide surface protection to the blanket from external damage. Thus providing superior insulation value and protection to your parts/components or surface.

Product Index

|

INDEX

|

COM

|

STD

|

HC

|

HA

|

HZ

|

HAZ

|

|||||

|

Classification Temperature(℃)

|

1050

|

1260

|

1260

|

1360

|

1430

|

1400

|

|||||

|

Working Temperature(℃) ≤

|

1000

|

1050

|

1100

|

1200

|

1350

|

1200

|

|||||

|

Slag Content(%) ≤

|

20

|

15

|

15

|

15

|

12

|

12

|

|||||

|

Bulk Density(kg/m3)

|

96~160

|

|

|

|

|

|

|||||

|

Thermal Conductivity

(W/m.k)

|

0.086

(400℃)

0.120

(800℃)

|

0.086

(400℃)

0.120

(800℃)

|

0.086

(400℃)

0.110

(800℃)

|

0.092

(400℃)

0.186

(1000℃)

|

0.092

(400℃)

0.186

(1000℃)

|

0.98

(400℃)

0.20

(1000℃)

|

|||||

|

Permanent Linear Change×24h(%)

|

-4/1000℃

|

-3/1000℃

|

-3/1100℃

|

-3/1200℃

|

-3/1350℃

|

-3/1400℃

|

|||||

|

Modulus of Rupture(MPa)

|

0.08~0.12

|

|

|

|

|

|

|||||

|

Al2O3(%) ≥

|

44

|

45

|

45

|

50

|

39

|

39

|

|||||

|

Fe2O3(%) ≤

|

1.0

|

1.0

|

0.2

|

0.2

|

0.2

|

0.2

|

|||||

|

Al2O3+SiO2(%) ≤

|

98

|

99

|

99

|

99

|

84

|

90

|

|||||

|

ZrO2(%) ≥

|

|

|

|

|

15

|

5~7

|

|||||

Applications

Ceramic Fiber Blankets

Aluminum Foil Faced

Ceramic Fiber Blanket

Heat shield blankets are designed for passive fire protection applications and use in high-temperature systems. It has an

extensive range of applications for fire protection and insulation purpose. It can be applied for kiln, forge, furnace, boiler,

foundry, chimney, fireplace, and pipe insulation. It is also widely used as insulation in HVAC setups. Besides this, it can also

be used during scorching, burning, and charring while soldering, brazing, welding, grinding, or cutting.

Production Workshop

Package&Warehouse

Hot Searches