- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

star glass

-

Model Number:

-

star laminated glass

-

Shape:

-

rectangle

-

Certificate:

-

CCC/ISO9001/CE/EN12150

-

Processing:

-

Cutting Edging Drilling Tempering

-

Deep processing:

-

Tempered, Insulated

-

Edge:

-

Fine Polished Edge

-

Sample:

-

Available(free Sample)

Quick Details

-

Application:

-

Bathroom, Outdoor, Park, Office Building

-

Usage:

-

Decoration, Curtain Wall, Bulletproof

-

Thickness:

-

3mm-30mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

star glass

-

Model Number:

-

star laminated glass

-

Shape:

-

rectangle

-

Certificate:

-

CCC/ISO9001/CE/EN12150

-

Processing:

-

Cutting Edging Drilling Tempering

-

Deep processing:

-

Tempered, Insulated

-

Edge:

-

Fine Polished Edge

-

Sample:

-

Available(free Sample)

Jumbo Size Annealed PVB SGP Clear Float Laminated Glass EN12150

Product Description

|

Product Name

|

Laminated glass

|

|

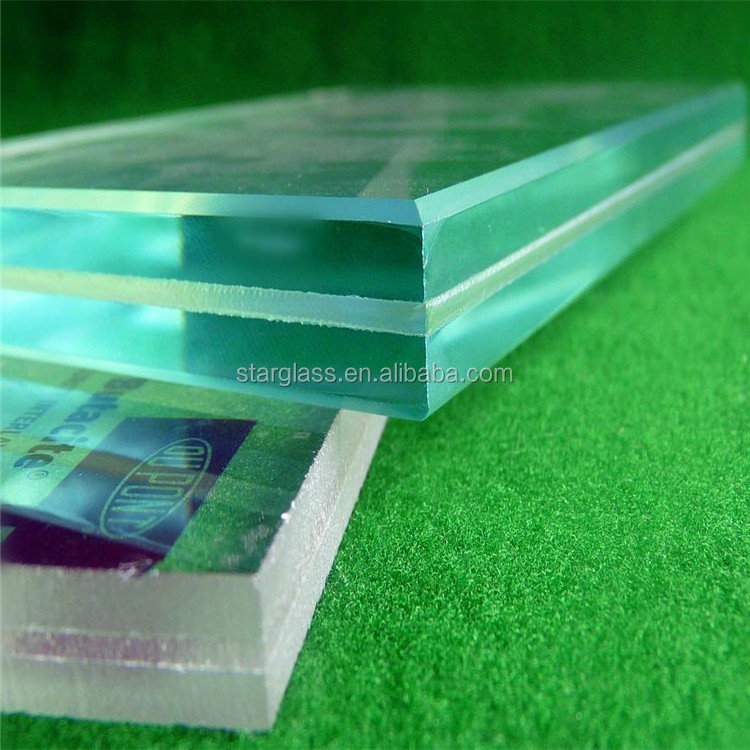

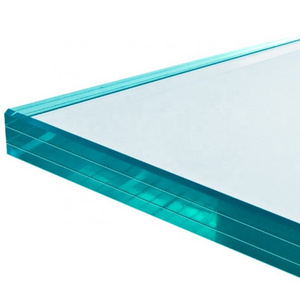

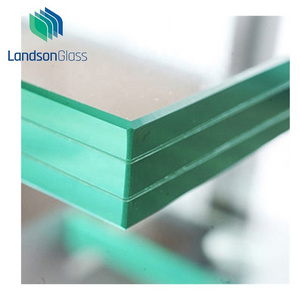

Glass thickness

|

3+3mm, 4+4mm, 5+5mm, 6+6mm, 8+8mm, 10+10mm, 12+12mm

|

|

PVB thickness

|

0.38mm, 0.76mm, 1.14mm, 1.52mm

|

|

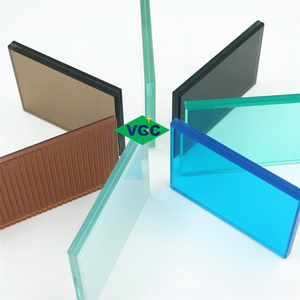

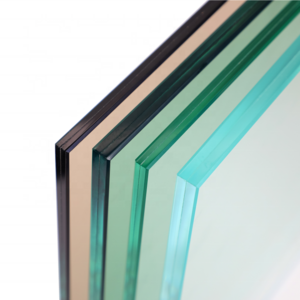

Color

|

Clear, ultra clear, green, blue, milk, grey, bronze, red, purple, etc

|

|

Size

|

1830*2440mm, 2140*3300mm, 2250*3300mm, 2140*3660mm or customized

|

|

Edge

|

Polished edge (c edge, pencil edge), flat edge, drill hole, etc

|

|

Payment

|

30% deposit, 70% after B/L copy

|

|

Package

|

Sea worthy wooden crate with interlayer paper

|

|

Delivery time

|

15 days

|

Detailed Images

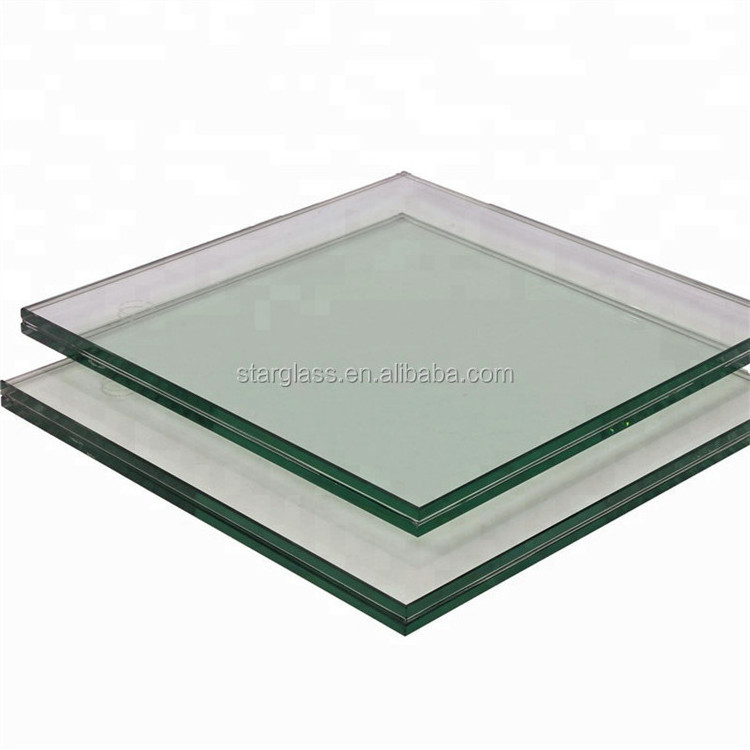

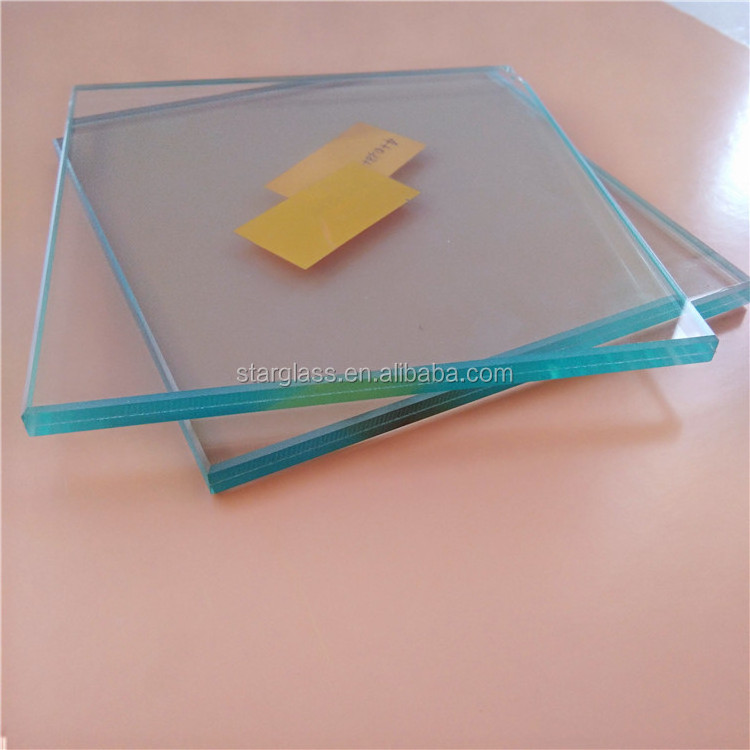

LAMINATED GLASS is made by good quality adhesive interlayer and advanced bond technology. Laminated Glass is a kind of glass made up of two or more sheets of top quality glass bonded together with PVB or SGP interlayer.

After the PVB interlayer has been placed between the glass sheets, the whole assembly is subjected to heat and pressure. This makes the complete adhesion of the vinyl and the glass. In the event of breakage, the glass fragments remain bonded to the plastic interlayer. The thickness of the monolithic glass and the thickness of the PVB interlayer film, different colors, will give different performance. Among those, the color of clear is most popular.This makes the complete adhesion of the vinyl and the glass.

After the PVB interlayer has been placed between the glass sheets, the whole assembly is subjected to heat and pressure. This makes the complete adhesion of the vinyl and the glass. In the event of breakage, the glass fragments remain bonded to the plastic interlayer. The thickness of the monolithic glass and the thickness of the PVB interlayer film, different colors, will give different performance. Among those, the color of clear is most popular.This makes the complete adhesion of the vinyl and the glass.

Features

The PVB interlayer withstands penetration from impact. Even if the glass cracks, splinters will adhere to the interlayer and not scatter.

In comparison with other kinds of glass, laminated glass has much higher strength to resist shock, burglary, burst and bullets

In comparison with other kinds of glass, laminated glass has much higher strength to resist shock, burglary, burst and bullets

Application

1. Windows,doors,

2. Skylights and canopies,

3. Glass stairs,balustrades,

4. Automotive windshield,

5. Facades and curtain walls

2. Skylights and canopies,

3. Glass stairs,balustrades,

4. Automotive windshield,

5. Facades and curtain walls

Hot Searches