- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized custom

-

Product Name:

-

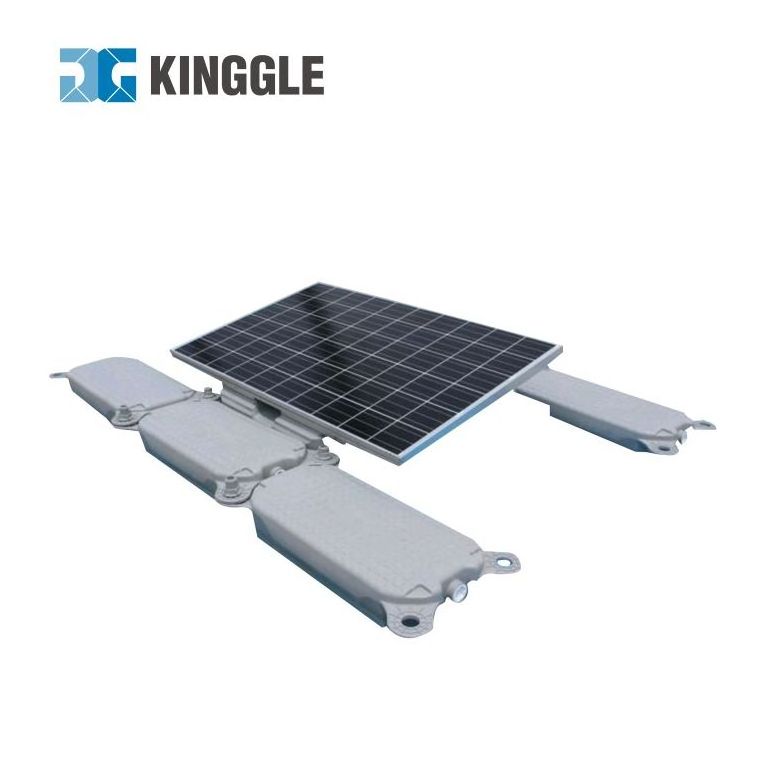

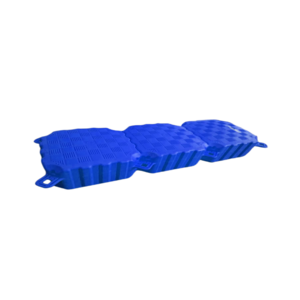

plastic solar floating buoy platform boats blow mold

-

Mould material:

-

45#/50#/P20/718/2738/NAK80/S136

-

Design software:

-

CAD

-

Style:

-

100% customized

-

Cavity:

-

single/ multi

-

Manufacturing time:

-

30-40 days

-

Application:

-

Walkway

Quick Details

-

Shaping Mode:

-

Extrusion Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kinggle

-

Model Number:

-

Customized custom

-

Product Name:

-

plastic solar floating buoy platform boats blow mold

-

Mould material:

-

45#/50#/P20/718/2738/NAK80/S136

-

Design software:

-

CAD

-

Style:

-

100% customized

-

Cavity:

-

single/ multi

-

Manufacturing time:

-

30-40 days

-

Application:

-

Walkway

SINCE 1985

More than 30 years' development make our mold factory from a small to mdium-sized enterp a member of China Mould Association a star-rated mould company.

| Item | Description |

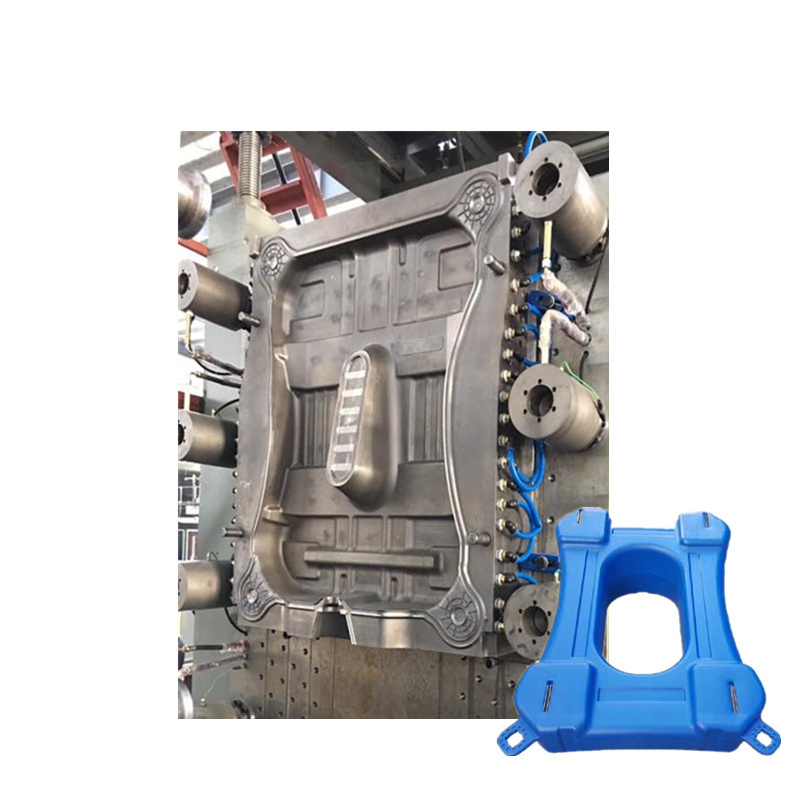

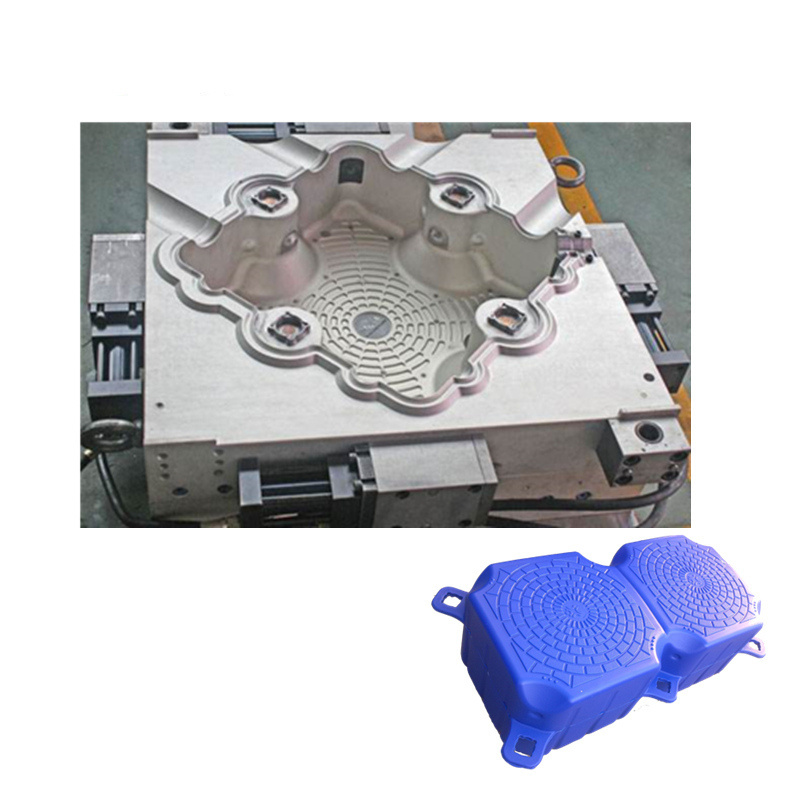

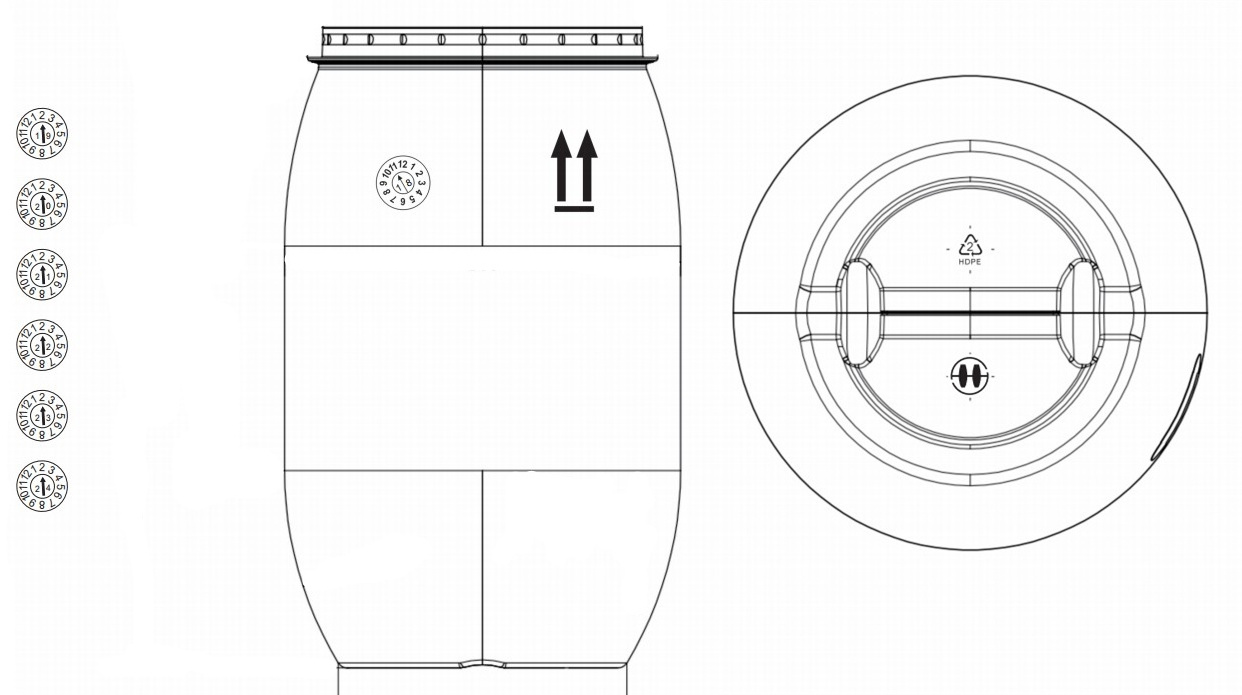

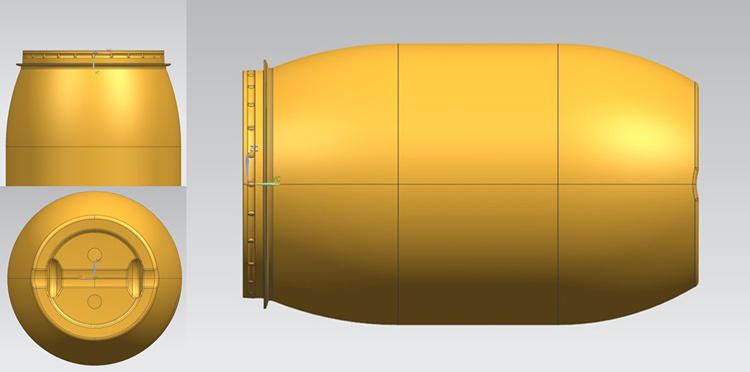

| Mold description | Plastic blow mold |

| Cavity | Single/ multi per request |

| Mold material |

Aluminium, P20, 4Cr13, S136, 45#, P20 etc. |

| Specification | According to customer's requirements |

| Design& program softewares | CAD/ CAM/ CAE etc. |

| Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/ Grinding machine,Punching/Drilling machine,Ultrasonec cleaning machine,etc |

| Package | Wooden case |

| Manufacturing time | 30-35 days |

| Payment terms | T/T or L/C |

| After-sales services | Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

How about our design ability?

We have own design work team to design drawing according to customer's request, such as 2D&3D product drawing, or 2D&3D mould struchture drawing. We will gald to share good idea for fashional design for our customer.

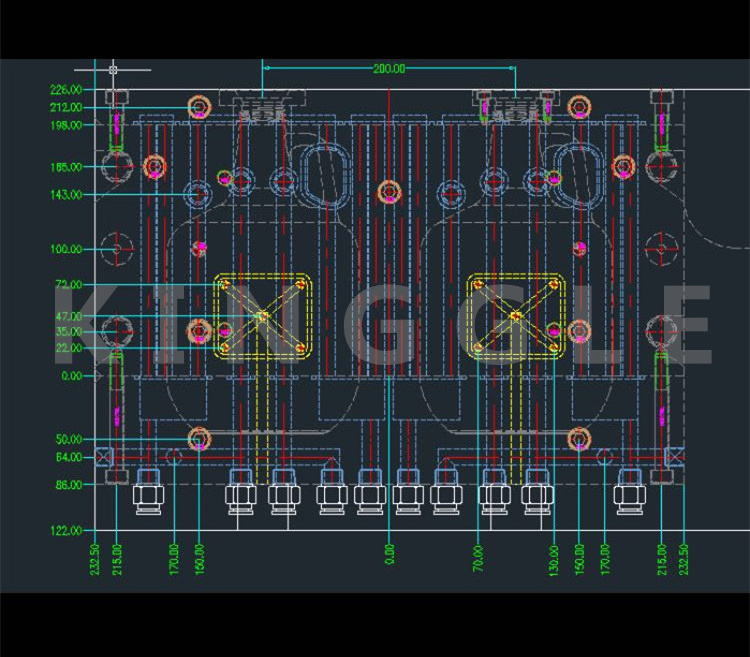

How can we help you improve output?

Cooling runner is most important of mold

Kinggle use "whole covering type cooling runner" , you can see the blue lines in the follow 2D draft. This design allows the mold to cool more quickly, increasing throughput.

How can we ensure the quality and fast delivery?

Each mold project will be followed by an engineer who have rich experience. Engineer will m ake a mold schedule to ensure that every step goes smoothly, ensuring quality and fast delivery .

| Cap mould | Bottle or drum mould |

| Other blow mold | Customization plastic mold |

Q1: Why chose Kinggle?

A: We have more than 30 years experience in blow molding machine line, and our professional team will help you make a most suitable solution to save your cost.

Q2: How to receive an quotation in the shortest time?

A: When you send us inquiry, please kindly make sure all details with us, such as quantity, cavity, sample, weight etc.

Q3: How to ensure the products' quality before shipment?

A: If you don't have time to visit our factory, we will be as your inspection worker. We will supply picture&check report or sample. (but need you to pay freight charge)

Q4: How about quality control in your factory?

A: “ Quality is the key point, do what customers need”. Kinggle machinery factory focuses on quality, quality control from beginning to the end. Every piece of goods is tested strictly before

packing and delivery.

The easiest contact way is click the bottom "Send" below