- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Fully Automatic Paper Production Iine

-

Dimension(L*W*H):

-

10000*3000*2000mm

-

Weight:

-

12T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Dimensions:

-

10000*3000*2000mm

-

Edge Embossing unit:

-

steel to steel,Independent Pneumatic Control

-

Embossing unit:

-

roll steel to steel embossing

-

Programming Controller:

-

PLC

-

Stable Speed:

-

100cut/min

-

Color:

-

Silver,electrostatic spraying

-

Driving System:

-

Delta Servo Motor

-

Grinding System:

-

Pneumatic Sharpen,grinding time can be set

-

Main Driving:

-

Timming Belt,Chains,Gear Box

-

Certification:

-

CE

Quick Details

-

Application:

-

Machinery & Hardware

-

Packaging Material:

-

Wood

-

Voltage:

-

380V

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Fully Automatic Paper Production Iine

-

Dimension(L*W*H):

-

10000*3000*2000mm

-

Weight:

-

12T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Dimensions:

-

10000*3000*2000mm

-

Edge Embossing unit:

-

steel to steel,Independent Pneumatic Control

-

Embossing unit:

-

roll steel to steel embossing

-

Programming Controller:

-

PLC

-

Stable Speed:

-

100cut/min

-

Color:

-

Silver,electrostatic spraying

-

Driving System:

-

Delta Servo Motor

-

Grinding System:

-

Pneumatic Sharpen,grinding time can be set

-

Main Driving:

-

Timming Belt,Chains,Gear Box

-

Certification:

-

CE

Functions and Features

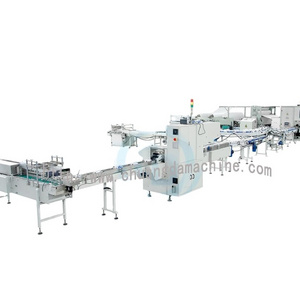

1 . Automatic core feeding system, automatic log pusher after rewinding, then rewind the new log again.

2 . Automatic edge-trimming, core feeding; auto edge trimming, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

4. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

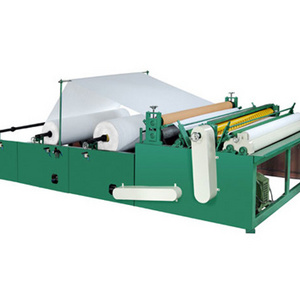

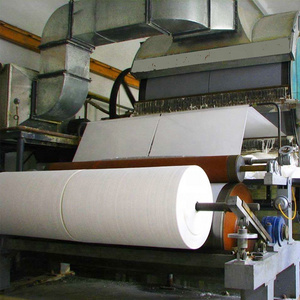

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts; each jumbo roll can be adjusted independently.

6 . Embossment Unit: adopt point to point embossing rollers, making the two layers match well, the paper is soft and has clear patterns

7. Adopt jogging switches for wearing the paper, easy and safe to operate.

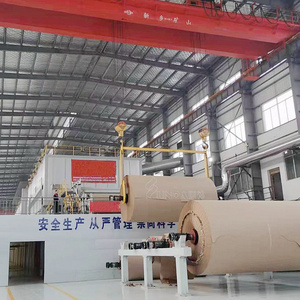

The Main Technical Parameters

|

Jumbo Roll Max Width |

1750mm (Other size can be specified) |

|

Jumbo Roll Diameter |

Φ 1100mm |

|

Jumbo Roll Inner Diameter |

3inches(76.2mm) |

|

Finish Product Diameter |

Φ9 0- φ28 0mm |

|

Finish Product Inner Diameter |

φ 38- φ 48mm |

|

Perforation Distance |

100-150mm |

|

Production Speed |

0-230m/min |

|

Parameter Set |

HMI, Touch Screen |

|

Pneumatic System |

3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa ( Provide by user ) |

|

Total Power |

7.5-15KW(depends on model and configuration) |

|

Unwind Stands |

2 or 3 Stands |

|

Unwinding Transmission |

Frequency Stepless Speed Regulation |

|

Rewinding Unit |

With Core or Coreless |

|

Dimension |

7800X3000X1720mm |

|

Weight |

3500~4500kg |

Warehouse&Exhibition

Contact