- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kaitelver

-

Raw material:

-

Cordierite, Mullite, Corundum mullite

-

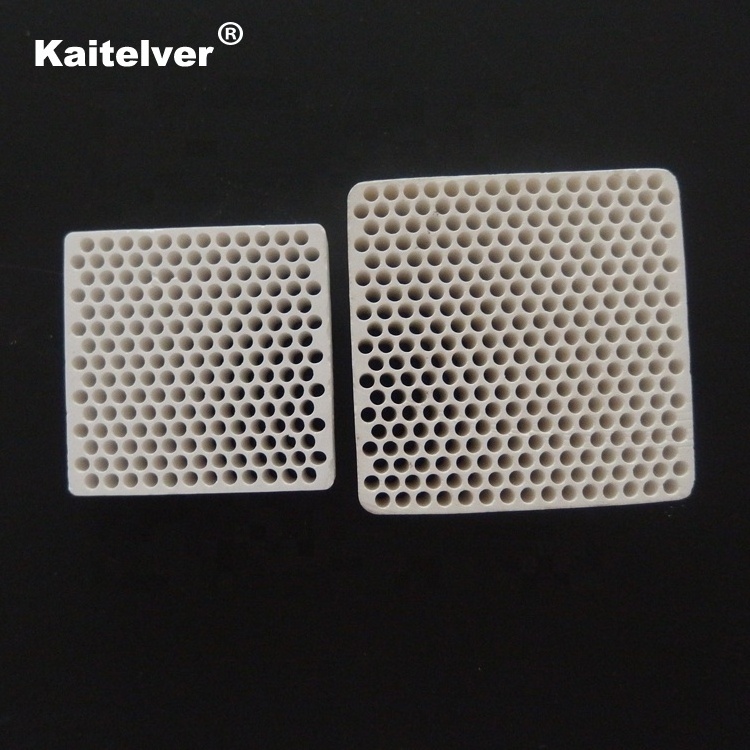

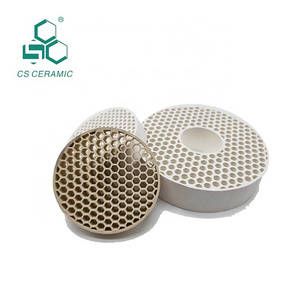

Shape:

-

Square and round

-

Hole type:

-

Round, square and delthyrium

-

Aperture:

-

2-3 mm

-

Size:

-

25mm to 100 mm

-

Thickness:

-

12 mm to 22mm

-

Mesh sizes:

-

100, 200, 300 CPSI

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

KT- CHF

-

Brand Name:

-

Kaitelver

-

Raw material:

-

Cordierite, Mullite, Corundum mullite

-

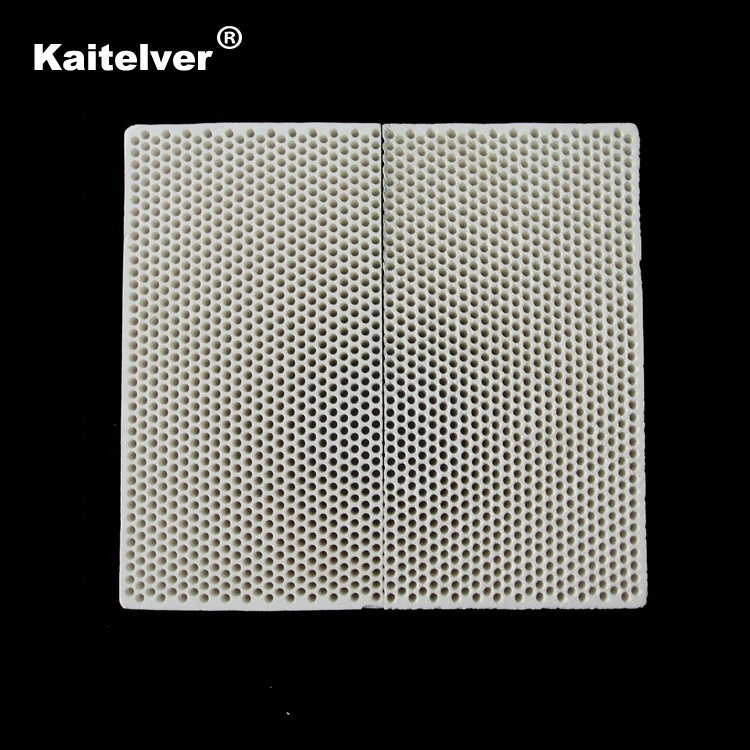

Shape:

-

Square and round

-

Hole type:

-

Round, square and delthyrium

-

Aperture:

-

2-3 mm

-

Size:

-

25mm to 100 mm

-

Thickness:

-

12 mm to 22mm

-

Mesh sizes:

-

100, 200, 300 CPSI

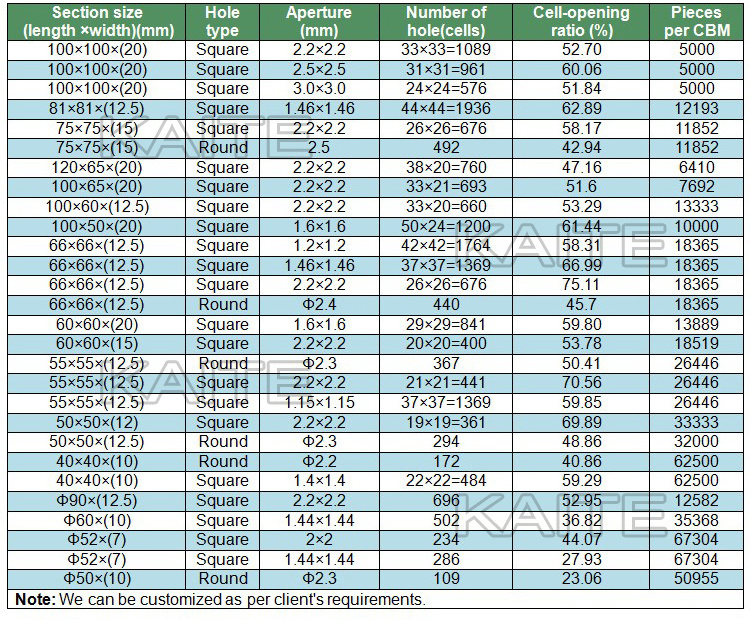

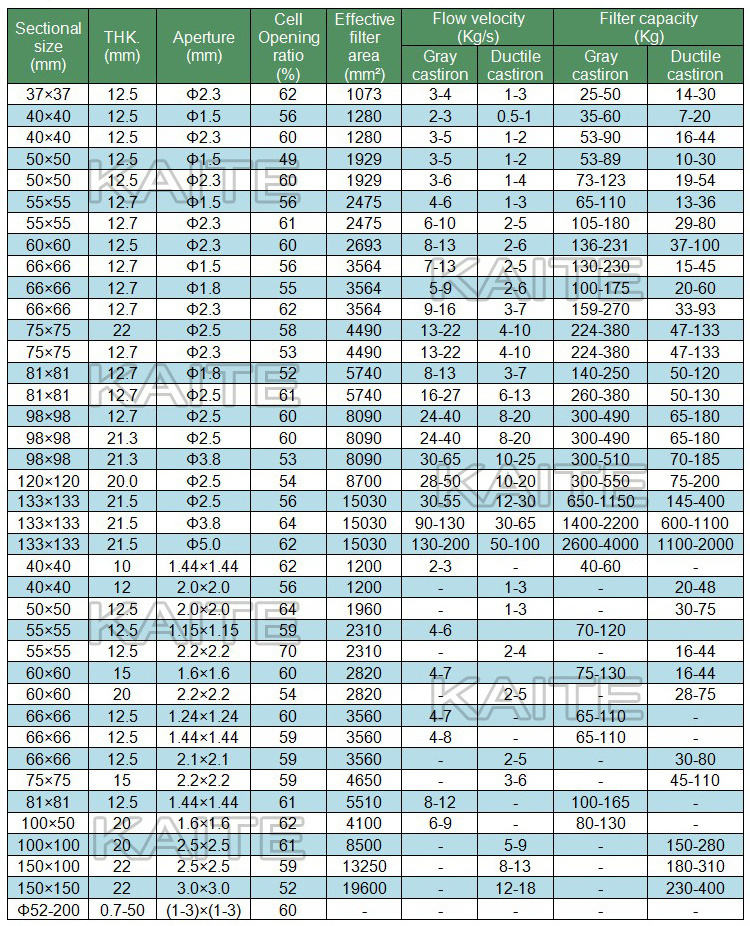

At present, honeycomb ceramic filters have already begun to be applied to a lot of casting fields, in order to improve the dependability of casting performance and yield of the casting.

Honeycomb ceramic filter also can be called extruded ceramic filter or molten metal cellular filter. It is mainly used for filtering of molten metal, especially suitable for filtering gray iron, cast iron, copper, aluminum, alloys, etc. It uses high-density straight-pore honeycomb structure, and it has larger specific surface, uniform aperture, stable quality, high mechanical strength, good thermal shock resistance.The straight-pore design ensures good balance flow rate and reduce the vortex. These design features will completely remove impurities and slag from molten metal, obviously improve metal structure and appearance quality, reduce the defective index of the casting, prolong the working life of the casting and reduce the casting cost.

We can produce different appearance specifications, pore diameter, wall thickness and hole type of filter, and we are able to satisfy any gating system requirements.

Technology:

Extruded.

Pore density:

100PCSI, 200PCSI, 300PCSI, etc.

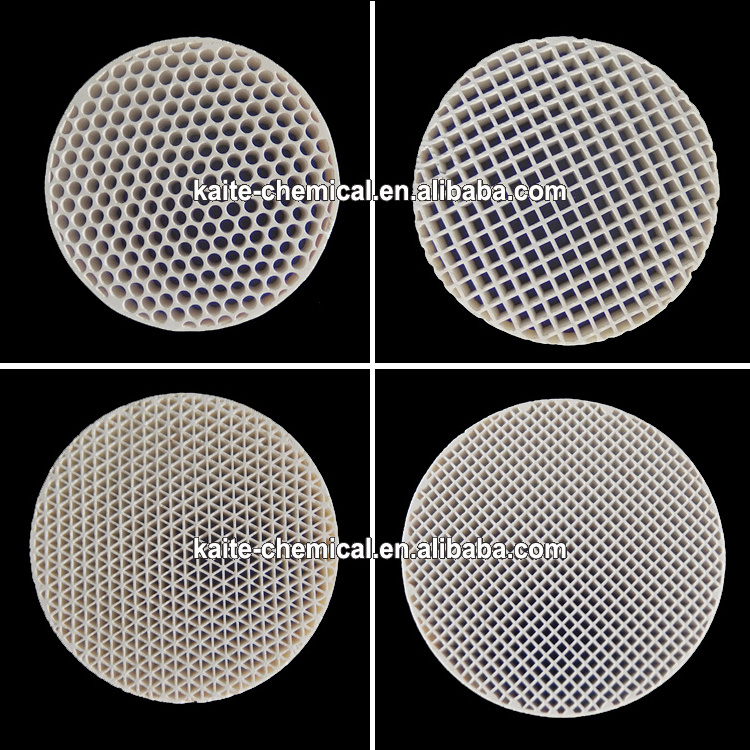

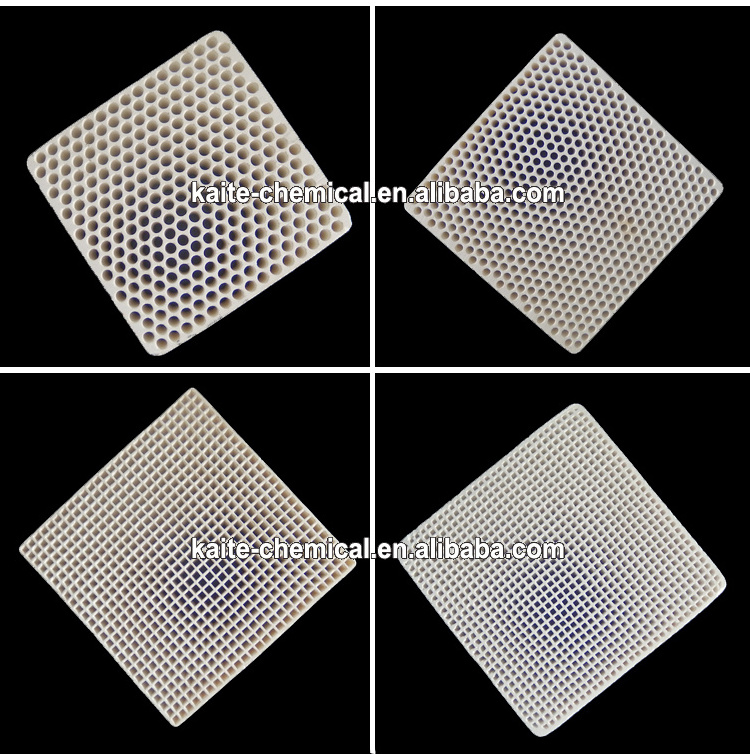

Cell shape:

Square, round, hexagon, triangle.

Available range of size:

25 mm to 200 mm.

Available range of thickness:

12 mm to 22mm or as per client’s requirements.

Appearance shape:

Round, square and rectangle

Material:

Cordierite, mullite, corundum mullite, zircon mullite, zirconia-corundum, high aluminum, silicon carbide and etc.

Maximum working temperature:

1350°C, 1500°C, 1600°C, 1650°C.

Application:

Grey iron, ductile iron and malleable iron, aluminum, aluminum alloy, copper, stainless steel and so on.

|

Material |

Cordierite |

Mullite |

Corundum Mullite |

Zircon Mullite |

Zircon Corundum |

|

Al 2 O 3 (%) |

35-37 |

50-60 |

65-70 |

68-73 |

68-73 |

|

Hole type |

Square, round, hexagon and triangle |

||||

|

Milli hole (μm) |

2-3 |

||||

|

Holes/inch 2 |

100pcsi, 200pcsi, 300pcsi |

||||

|

Coefficient of thermal expansion (×10 -6 /°C) |

≤1.8 |

≤4.0 |

≤5.5 |

≤5.5 |

≤5.5 |

|

Softening temperature (°C) |

1390 |

1550 |

1600 |

1650 |

1700 |

|

Compressive strength (MPa) |

≥12 |

≥15 |

≥15 |

≥15 |

≥15 |

|

Max. working temperature (°C) |

1350 |

1500 |

1550 |

1580 |

1650 |

|

Application |

Aluminum alloy casting |

Grey cast iron, ductile cast iron and copper alloy casting |

Stainless steel casting |

||

1. Purify metal liquid; get rid of non- metal impurity and gas.

2. Make the metal liquid flowing at stable speed and reduce the swirl.

3. Simplify the gating system and improve the producing rate.

4. Reduce the bubbles in casting and optimize metal structure.

5. Improve surface quality and mechanical performance of casting.

6. Reduce the rejection rate of casting, prolong the casting working life and reduce casting cost.