- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TENGTIAN

-

Voltage:

-

380/440/410/240

-

Power:

-

200KW

-

Dimension(L*W*H):

-

40X6X8 m

-

Weight:

-

20000 kg

-

Product name:

-

Mild steel pipe production line

-

Features:

-

fast change roll

-

Material:

-

coil strip

-

Function:

-

roll forming

-

Welding type:

-

hifrequency welding

-

Control system:

-

PLC control

-

Export port:

-

Xingang port at Tianjin

-

Speed:

-

0-100m/min

-

Pipe shape:

-

round and square

-

Pipe application:

-

construction/decoration/drain and energy supply

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

50-100 ton per day

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TENGTIAN

-

Voltage:

-

380/440/410/240

-

Power:

-

200KW

-

Dimension(L*W*H):

-

40X6X8 m

-

Weight:

-

20000 kg

-

Product name:

-

Mild steel pipe production line

-

Features:

-

fast change roll

-

Material:

-

coil strip

-

Function:

-

roll forming

-

Welding type:

-

hifrequency welding

-

Control system:

-

PLC control

-

Export port:

-

Xingang port at Tianjin

-

Speed:

-

0-100m/min

-

Pipe shape:

-

round and square

-

Pipe application:

-

construction/decoration/drain and energy supply

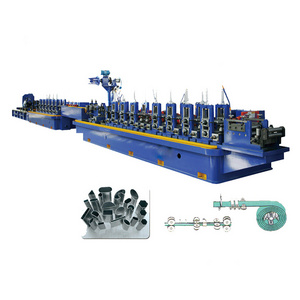

HG127 P ipe mill line is designed to produce welded pipes of round pipe 63-127 mm , 1.5-4.0 mm in thickness , square pipe 40x40-100x100m, thickness 1.5-3.5 mm. Adopting roll pass design, the production line can manufacture welded steel pipes with good quality machining and high precision assembling.

ERW pipe rolling making machine production line and steel tube making equipment steel pipe mill line for sale

|

1) Loading car |

The loading car is used for make the steel coil from loading position to uncoiler.at the same time loft oil cylinder,so that the steel coil inner hole is accurately set on the cone of uncoiler, after the uncoiler tension, push back to the original position. |

| 2) Uncoiler |

1. expansion and cantilever mandrels. 2. Contains two main parts: main body and the fixed base. 3. Equipped with pneumatic system to satisfy the needs of expanding, contracting and braking of the mandrels. 4. Mandrel consists of four-bar linkages that could move radially at the same time. 5.The four-bar linkages in two groups are fitted on two shafts respectively. Powered by air cylinder, they expand and contract radially. |

| 3) S traight head machine |

Th is machine is used to open the coil head and smoothly introduce the next device to a smooth machine. The pressure roller on the head is mainly used to press the head of the roll to prevent the scatter roll from scattering, and the shovel is shovel smoothly. The pressure roller rotates under the motor. For the opening machine, it is a help roller. There is a straight head roller, which is mainly the curved pressure of the head of the steel, cooperate with the shovel header, and make it forward along the shovel. The guide roller leads the material into the next process. |

|

4)Pinch leveling machine |

The pinching machine is divided into three parts: clamping materials, the flat house roller, and the flattering machine transmission. The five -roller smoothing can change the passing steel through the up and down adjustment of the five rollers to a straight state, and the transmission part of the ingening machine provides motivation for the pinhris roller and the flat roller. |

|

5)Automatic shear and welder |

It is used to cut the irregular ends of the strips and then connect the strips by welding. So it can let the line runing without stop when the before coil finish |

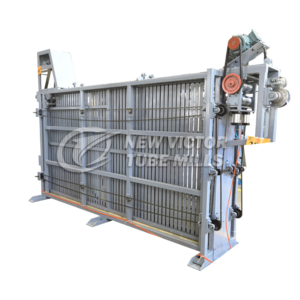

| 6)Horizontal accumulator |

This machine is between shear welder and host ( forming sizing mill) , use for after a roll of strip steel are used up, before the next roll strip since prepared from uncoiling, shearing and butt welding time to ensure that the host ( forming sizing mill) continuous production and store enough strip steel. |

|

7)Forming and sizing mill |

Forming & Sizing Mill adopts roller type forming principle and high-frequency induction welding. The strip is fed into the forming machine by the feeding device in the mill and the forming roller continuously rotate and press the strip into the required shape. Due to the skin and the kindred effect, the high-frequency current is concentrated on the weld joint that is heated rapidly and reaches the welding temperature. The tube seam is welded under the pressure of squeeze rollers. The finished welded tube with required size can obtained after the cooling, sizing and primary straightening. |

| 8)Cutting saw |

It is used to precisely cut the pipe to length automatically under the condition that the pipe continuously delivered from the mill at high speed. |

| 9) Hifrequency Welder |

Weld the seam |

| 10) Runout Transit table |

Transit the finished pipe to the collection table |

Name: tube mill, pipe mill, pipe production line, steel pipe making machine, steel tube mill, erw tube making machine,GI steel pipe making machine,round pipe making machine, galvanized steel pipe making machine, iron tube production line

Machine List