- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

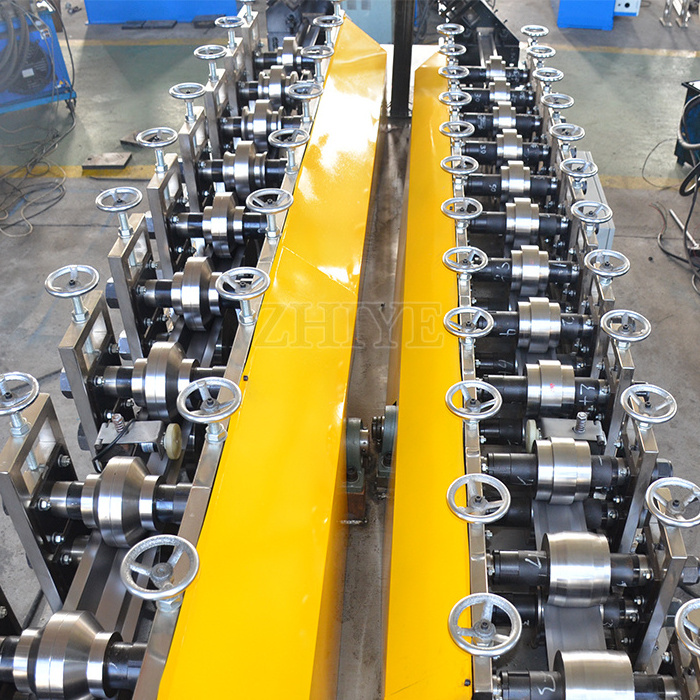

Metal Sheet Roof And wall Making Machine:

-

blue and yellow or as client requirement

-

Sheet Metal Roof Panel Rolling Machinery:

-

material steel IBR Metal Sheet Forming Line

-

Sheet Metal Roof Roll Former machinery:

-

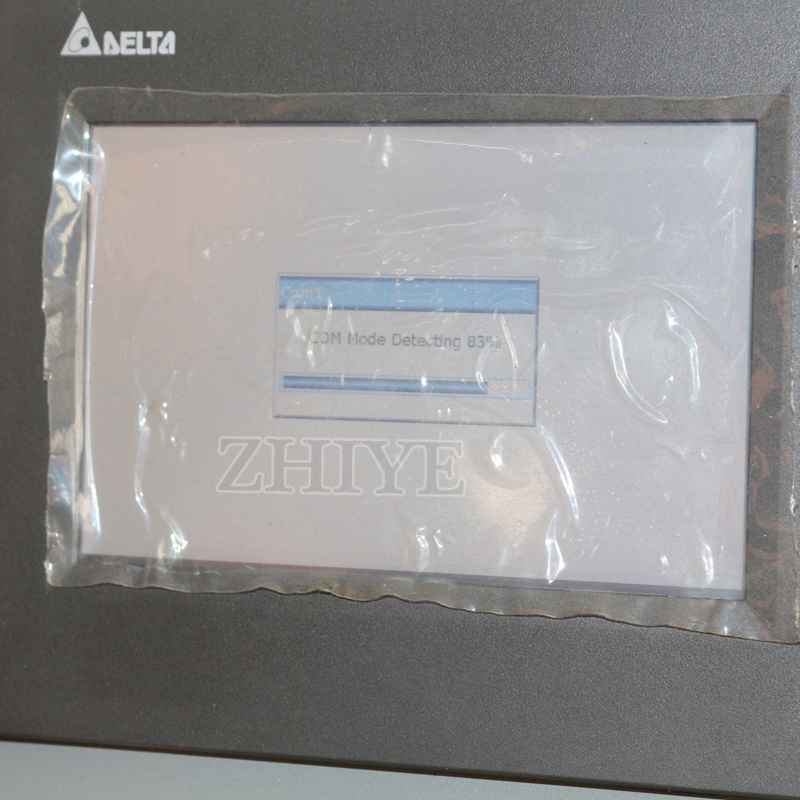

control system:Delta PLC

-

Sheet Metal Roof Roll Former machine:

-

power: 4+4kw IBR Metal Sheet Forming Line

-

Single Layer Wall Roll Forming Machine:

-

transmission model: gear and chain

-

Single Roof Panel Forming Machine:

-

controlling model: PLC controlling system

-

Single Roof Sheet Roll Forming Machine:

-

Material of blades: Cr12 quenched

-

Corrugated Sheet Roll Forming Machine:

-

Power supply : hydraulic power

-

Corrugated Sheet Roll Formers machine:

-

coil max width: 1250mm

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Metal Sheet Roof And wall Making Machine:

-

blue and yellow or as client requirement

-

Sheet Metal Roof Panel Rolling Machinery:

-

material steel IBR Metal Sheet Forming Line

-

Sheet Metal Roof Roll Former machinery:

-

control system:Delta PLC

-

Sheet Metal Roof Roll Former machine:

-

power: 4+4kw IBR Metal Sheet Forming Line

-

Single Layer Wall Roll Forming Machine:

-

transmission model: gear and chain

-

Single Roof Panel Forming Machine:

-

controlling model: PLC controlling system

-

Single Roof Sheet Roll Forming Machine:

-

Material of blades: Cr12 quenched

-

Corrugated Sheet Roll Forming Machine:

-

Power supply : hydraulic power

-

Corrugated Sheet Roll Formers machine:

-

coil max width: 1250mm

This

Galvanized Drywall Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine

takes GI/PPGI as raw material, through a series steps and can produce the metal roofing sheets.

Galvanized Drywall Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine

produce building material so It is usually use for construction. To be more precise that's widely used in various industrial factory ,beauty spot, holiday village building, hotel,exhibition ,easy steel building manufacturing ,and have features such as nice appearance and durable.

Our other related main products are Trapezoidal Roof Panel Roll Forming Machine,Glazed Roofing Tile Roll Forming Line,Roof Ridge Cap Production Line,C/u/z Purlin Roller Former Machine,Roller Door Panel Rolling Forming Machine,Floor Decking Panel Rolling Forming Machine,Downpipe Rain Gutter Roll Forming Machine,Light Steel Frame Cold Roll Forming Machine,Double Layer Roof Sheet Roll Forming Machine,Sandwich Panel Wall Roof Roll Forming Machine

High Frequency Welding Pipe Making Machine

Cut To Length Machine Lines

Downpipe Steel Roll Forming Machine

Floor Decking Panel Rolling Forming Machine

Light Steel Frame Cold Roll Forming Machine

Shelf Racking Profile Cold Roll Forming Machine

Highway Guardrail Cold Roll Forming Machine

Sandwich Panel Roll Forming Machine

C Z U Purlin Cold Rolling Forming Machinery

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5T

Inner diameter: 500-508mm

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat. Parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron

Material of rollers: 45# steel, roller surfaces polishing, hard plating. The polished surface and the heat treatment towards the molds also can keep the molding. Plate surface smooth and not easy to be marked when it is being stamped.

Power: 11KW, Hydraulic oil:46#.

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.