- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

12150*2600*3950

-

Weight:

-

20 KG

-

After-sales Service Provided:

-

Field installation

-

Color:

-

Iron Grey

-

After-sale service:

-

For whole using life

-

Test&Installation:

-

Engineer assigned

-

Spare parts supply:

-

For whole year

-

Supply Ability:

-

30 Set/Sets per Month

-

Packaging Details:

-

Standard Container

-

Port:

-

Shanghai

-

Keyword:

-

mobile sand making machine

Quick Details

-

Application:

-

Granite, marble, basalt, limestone

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZENITH

-

Dimension(L*W*H):

-

12150*2600*3950

-

Weight:

-

20 KG

-

After-sales Service Provided:

-

Field installation

-

Color:

-

Iron Grey

-

After-sale service:

-

For whole using life

-

Test&Installation:

-

Engineer assigned

-

Spare parts supply:

-

For whole year

-

Supply Ability:

-

30 Set/Sets per Month

-

Packaging Details:

-

Standard Container

-

Port:

-

Shanghai

-

Keyword:

-

mobile sand making machine

mobile sand making machine | flexible & efficient | 10-650t/h available | for concrete demolition & small-scale aggregate production

1. China wholesale mobile sand making machine for sale

2. Extremely Reliable

3. Easy Maintanence

4. High Efficience

5. ISO 9001., CE

We supply various mobile sand making machine at the best price.

GET PRICE NOW >>> wechat/whatsapp: +86-15021033742

[Feed]0-40mm

[Final]0-5-10-26mm

[Capacity]260t/h

[Equipment]K3V1145S-2 Portable Impact Crusher

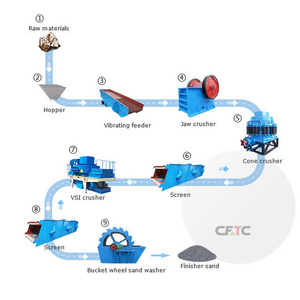

Introduction of mobile sand making machine for sale

mobile sand making machine for sale is researched and designed by our experienced engineers. It is of stable performance and beautiful structure. It is widely used in road &bridge construction, building, mining and other fields. The mobile sand making machine can be configured to jaw, impact, cone and vsi. It is high performance and cost effective.And it will maximize your quarry,mining and construction business profits. mobile sand making machine for sale is of high cost-performance ratio, and it is reliable in performance and reasonable in structure. mobile sand making machine for sale applies the advanced technology with the international level. mobile sand making machine is widely used in road & bridge construction, metallurgy and so on.

mobile sand making machine for sale component

1.Vibrating feeder, two types of GZD and ZSW to meet user’s different processing capacity;

2.First crushing: Jaw crusher, or Impact crusher, or cone crusher to meet user’s choise

3.Secondary crushing: fine jaw crusher, or impact crusher, or cone crusher(spring type, spring and hydraulic type, hydraulic type)

4.Vibrating screen, YK series, linear series, DF series

5.Belt conveyor, stationary type, or mobile type sand stone production line

6.Steel structures, such as feed-in and discharge hoppers, stairways, guardrails, maintenance board, steel channel, etc.

7.Electric control cabinet sand stone production line

8. power generation set for choosing.

Application of mobile sand making machine

Zenith provides a complete line of stone production; the output is widely used in road, bridge, house, high building, railway, highway, water project as the type of construction material, such as aggregate, foundation stone, etc.

Advantages of mobile sand making machine

1.Complete stone production line, near to turn-key project;

2.Stationary type or mobile type for choosing

3.First class workmanship sand stone production line

4.Reliable quality with CE approved, reaching to European standard

5.Updating in design and function year by year, forms our own unique design by considering of saving more cost and

improve the processing capacity for user’s consideration.

6.Invention technical patent kept sand stone production line

mobile sand making machine parameters

Mobile jaw crusher:

Mobile (Portable) Jaw Crusher plant provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. It offers high efficient and low cost project plan without environment limit for the client.

| Model | Car Body | Feeder | Crusher | Belt Conveyor (standard configuration↵ ) | Engine (Optional) | Overall dimension (mm) | ||||

| Model | Feeding Size (mm) | Power (kw) | Model | Feeding Size (mm) | Power (kw) | Size(m) | Power(kw) | |||

| YF938J69-N | Two-Spindle | GZD960×3800 | 500 | 6-11 | PE600×900 | 500 | 6-75 | B800×8.5 | 200 | 12600×2550×3870 |

| YF1142J710-N | Three-Spindle | GZD1100×4200 | 580 | 6-11 | PE750×1060 | 630 | 8-90 | B1000×9.5 | 250 | 13900×2750×4320 |

| YF1349J912-N | Three-Spindle | GZD1100×4900 | 750 | 6-22 | PE900×1200 | 750 | 8-130 | B1200×10.5 | 270 | 15450×2950×4380 |

| YF1349J811-N | Three-Spindle | GZD1300×4900 | 750 | 6-22 | PEW860 | 720 | 6-132 | B1200×10.5 | 320 | 15450×2950×4380 |

| YF1349J1120-N | Three-Spindle | GZD1300×4900 | 750 | 6-22 | PEW1100 | 930 | 8-185 | B1200×10.5 | 400 |

15450×2950×4380

|

Mobile impact crusher plant:

Mobile (Portable) Impact Crusher plant provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. It offers high efficient and low cost project plan without environment limit for the clifent.

| Model | Car Body | Feeder | Crusher | Belt Conveyor (standard configuration) | Engine (Optional) | Overall dimension (mm) | ||||

| Model | Feeding Size (mm) | Power (kw) | Model | Feeding Size (mm) | Power (kw) | Size(m) | Power (kw) | |||

| YF938FW1214Ⅱ | Two-Spindle | GZD960×3800 | 500 | 6-11 | PFW1214II | 500 | 4-132 | B800×8.5 | 360 | 12600×2550×3870 |

| YF1142FW315Ⅱ | Three-Spindle | GZD1100×4200 | 580 | 6-15 | PFW1315II | 600 | 4-160 | B1000×9.5 | 400 | 13900×2750×4180 |

| YF1349FW318Ⅱ | Three-Spindle | GZD1300×4900 | 750 | 6-22 | PFW1318II | 700 | 4-200 | B1200×10.5 | 500 | 15450×2950×4180 |

| Y3S1860F1214-N | Three-Spindle | 3YK1860 | ≤400 | 4-22 | PF1214 | 350 | 6-132 | B800×8.5 | 360 | 14300×2830×4380 |

| Y3S2160F1315-N | Three-Spindle | 3YK2160 | ≤400 | 4-30 | PF1315 | 350 | 6-200 | B1000×8.5 | 500 | 14300×3190×4380 |

| Y3S1860FW214Ⅲ | Three-Spindle | 3YK1860 | ≤400 | 4-22 | PFW1214Ⅲ | 250 | 4-132 | B800×8.5 | 360 | 14300×2830×4380 |

| Y3S2160FW315Ⅲ | Three-Spindle | 3YK2160 | ≤400 | 4-30 | PFW1315Ⅲ | 300 | 4-160 | B1000×8.5 | 400 |

14300×3190×4380

|

Mobile cone crushing plant:

Mobile (Portable) Cone Crusher plant provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. It offers high efficient and low cost project plan without environment limit for the client.

| Model | Car Body | Vibrating Screen | Crusher | Belt Conveyor (standard configuration) | Engine (Optional) | Overall dimension (mm) | |||

| Model | Feeding Size (mm) | Power (kw) | Model | Feeding Size (mm) | Size(m) | Power (kw) | |||

| Y3S1848CS75 | Two-Spindle | 3YK1848 | ≤400 | 4-18.5 | 36(3′) | 6-75 | B800×7.5 | 200 | 13050×2830×4350 |

| Y3S1860CS160 | Three-Spindle | 3YK1860 | ≤400 | 4-22 | 51(4.25′) | 6-160/185 | B800×8.5 | 500 | 14300×2830×4380 |

| Y3S1860HP220 | Three-Spindle | 3YK1860 | ≤400 | 4-22 | HPC220 | 4-220 | B800×8.5 | 550 | 14300×2830×4380 |

| Y3S2160HP220 | Three-Spindle | 3YK2160 | ≤400 | 4-30 | HPC220 | 4-220 | B1000×8.5 | 550 |

14300×3150×4380

|

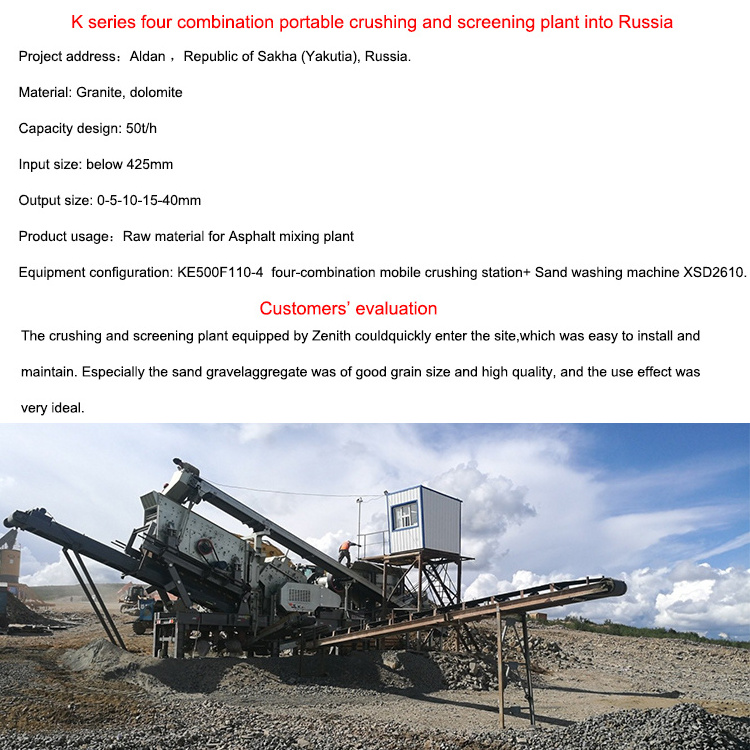

Mobile combined crushing plant:

The mobile conbined crusher plant has the advantages of easy transportation, low transportation cost, flexible configuration, convenient maintenance etc. It can be operated as independent units, or as two-stage crushing plant with primary and secondary crushing, or as three stage crushing plant with primary, secondary, and tertiary crushing according to different clients' requirements. Likewise, it can be easily adjusted to suit the crushing application by choosing feeding to crusher or feeding to screen options.

| Model | Y3S23F93J46S36 | |

| Car Body | Two-Spindle | |

| Feeder | Model | GZD960×3800 |

| Feeding Size(mm) | 500 | |

| Power(kw) | 11 | |

| Crusher 1 | Model | PE400×600 |

| Feeding Size(mm) | 350 | |

| Power(kw) | 6-37 | |

| Crusher 2 | Model | CS75 |

| Feeding Size(mm) | 115 | |

| Power(kw) | 75 | |

| Vibrating Screen | Model | 3YK1237 |

| Feeding Size(mm) | ≤200 | |

| Power(kw) | 15 | |

| Belt Conveyor(standard configuration) | Size(m) | B500×15 |

| Size(m) | B650×6 | |

| Size(m) | B650×10 | |

| Size(m) | B500×4 | |

| Engine(optional) | Power(kw) | 200 |

| Overall Dimension(mm) |

15600×2900×4450

|

|

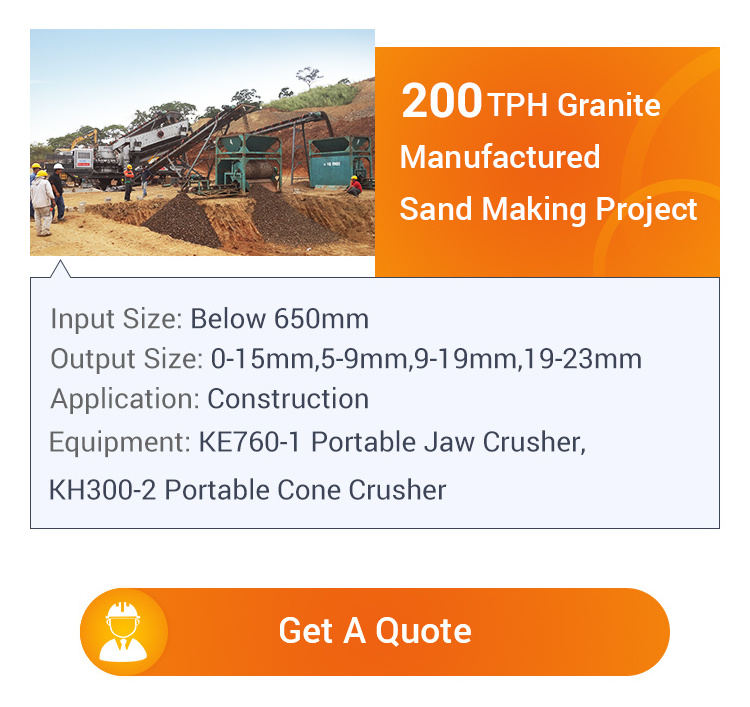

Finished Products

México 1200-1400 TPH Crushing Line

Project Profile

Location: Mexico

Raw Material: Magnetite

Input Size: 0-500mm

Output Size: 0-12mm,12-40mm

Capacity: 160-180TPH for 1 line (8 lines consist of 16 sets of mobile crushers)

Application: Construction

Equipment: YF1142J760-N Mobile Crushers*8; Y2S1860C51-N Mobile Crushers *8

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit zenith working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of Zenith, they are now strategically located home and abroad, working for our customers.

Shanghai Zenith is committed to providing users with the new, reliable and productive equipment. Zenith engineers have rigorously tested our products .

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.