- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Sunshine

-

Voltage:

-

220/380

-

Power (kW):

-

37

-

Weight:

-

2635 KG

-

Product Type:

-

Sheet

-

Inverter:

-

ABB

-

Extruder:

-

120/33

-

Color:

-

Blue

-

Function:

-

Sheet extruder

-

Capacity:

-

400-500kg/h

-

Control:

-

SIEMENS PLC+Touch Screen

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

72 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Sunshine

-

Voltage:

-

220/380

-

Power (kW):

-

37

-

Weight:

-

2635 KG

-

Product Type:

-

Sheet

-

Inverter:

-

ABB

-

Extruder:

-

120/33

-

Color:

-

Blue

-

Function:

-

Sheet extruder

-

Capacity:

-

400-500kg/h

-

Control:

-

SIEMENS PLC+Touch Screen

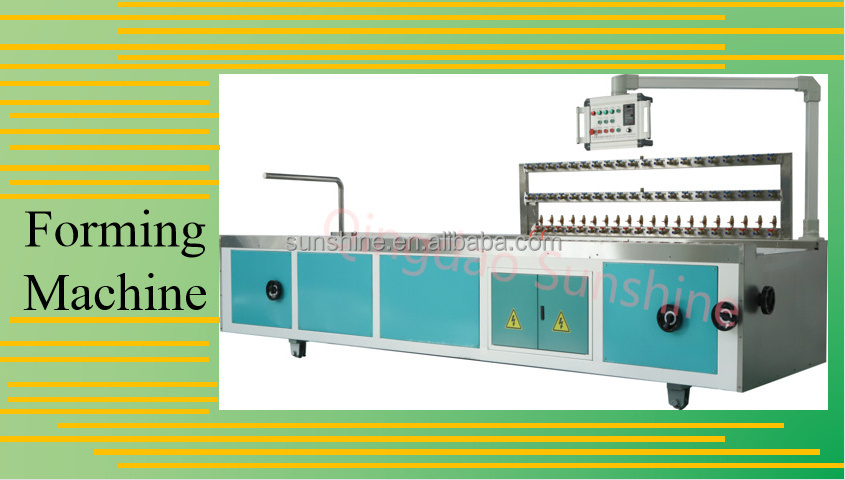

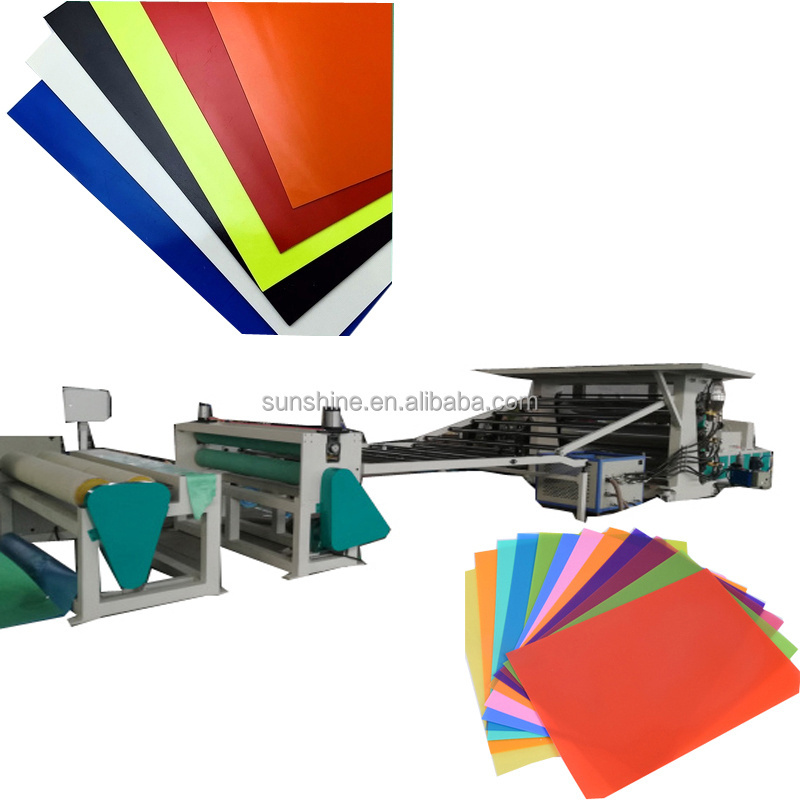

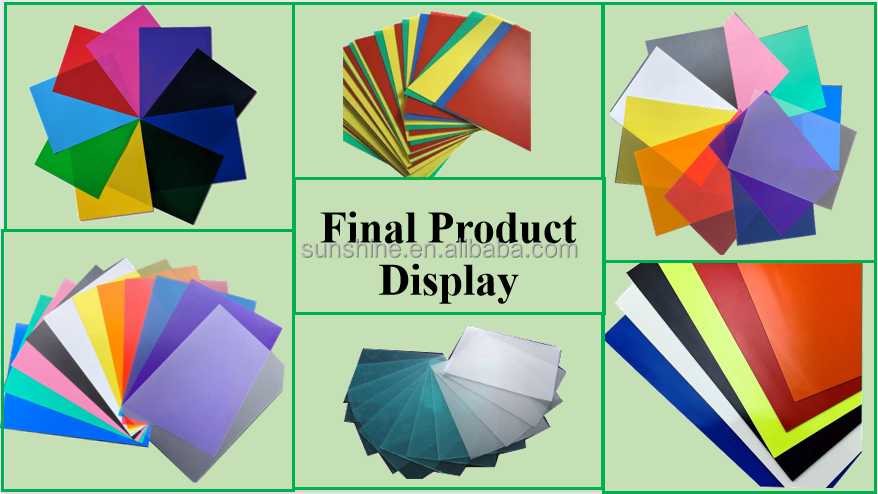

ABS PC Plastic Sheet Making Machine for Luggage Travel Bags Packaging

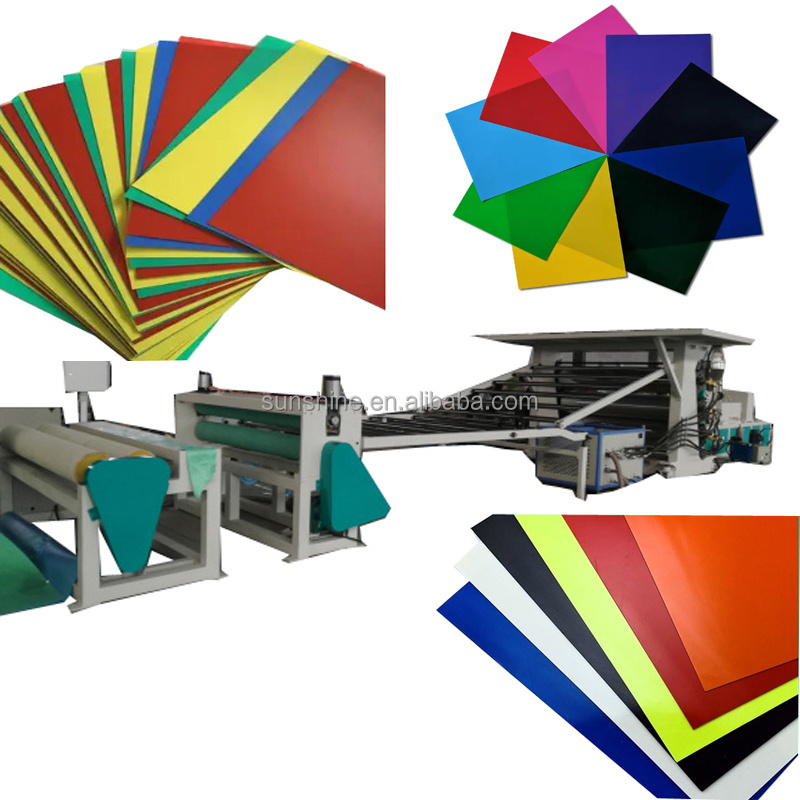

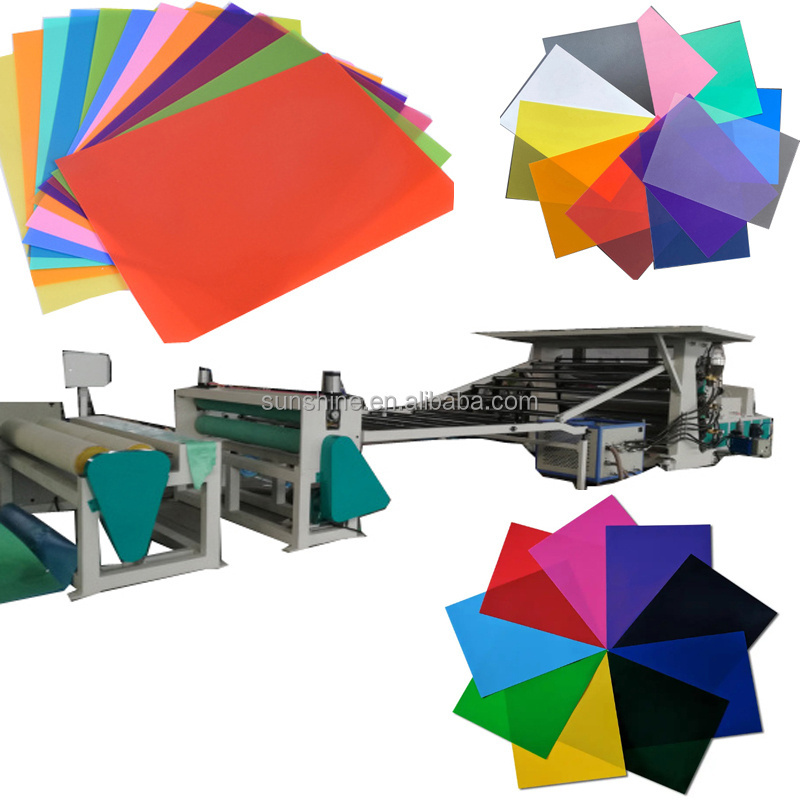

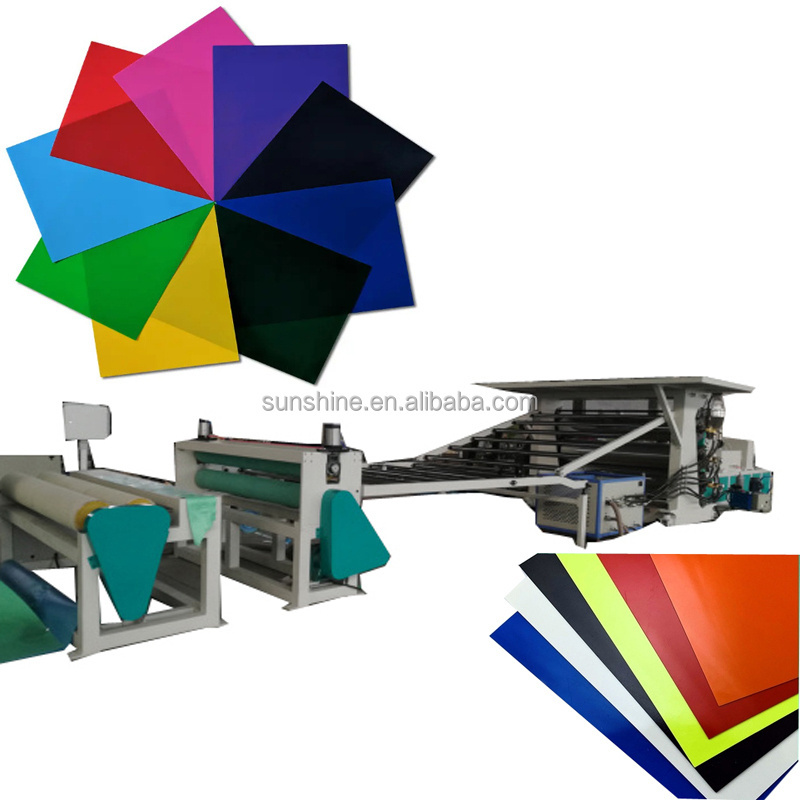

Description of Plastic Sheet

Plastic Sheet has characters of high strength and corrosion protection, with some padding can achieve enhance, toughen, flame retardant, anti-static electricity function, sheet surface can be embossed and polished, mainly used on producing plate, bowl, saucer, box, disposable plastic cup and so on hot forming products, also can be used on packing of food, vegetable, fruit, drinks, dairy, industrial parts and so on field like stationary sheet, printing sheet and so on.

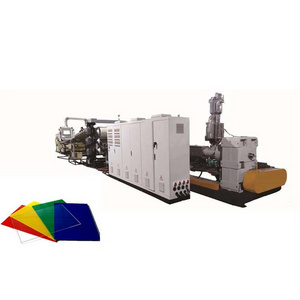

Main Technical Parameter of ABS PC Plastic Sheet Making Machine for Luggage Travel Bags Packaging

| Extruder Model | SJ120/38,SJ45/30 | SJ120/30 | SJ100/38,SJ45/30 | SJ100/33 |

| Raw Material | PC | PP/PE | PC | PP/PE |

| Products thickness (mm) | 3-30 | 2-15 | 2-10 | 2-8 |

| Products Width (mm) | 2100 | 2300 | 1300 | 1300 |

| Capacity (KG/H) | 450 | 400 | 300 | 200 |

| Motor Power (KW) | 200,18.5 | 132 | 132,18.5 | 110 |

Feature of ABS PC Plastic Sheet Making Machine for Luggage Travel Bags Packaging

1.Energy saving: 20% energy saving than normal machines.

2. Four self-designed major core technology of sheet extruder: extrusion system, die, roller, distributor. They are all invented and designed by ourselves. The core technology has many testing points and adopts electrical integration of double protection.

3.The operation fully reflects the man-machine engineering principle, it can make the function more entirely and the operation more simple.

4.The plasticizing effect of the sheet is very good. After the sheet formed and walking in curved line, it can make sure the stability of the sheet stock.

5.The heating system is controlled by high-grade china heater, stainless heater, inner-storing type single heating pipe and precision temperature-controlling die mould, is exact in controlling temperature, quickly in heating, good in keeping temperature, long life and save time and energy.