- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2500*1500*2000

-

Voltage:

-

380v

-

Power:

-

5.5

-

Weight (KG):

-

850

-

Raw material:

-

Coconut Shell

-

Name:

-

Airflow Carbonization Furnace

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Usage:

-

Biomass Charcoal Directly

-

Advantage:

-

Smokeless

-

Fuel:

-

Firewood

-

Capacity:

-

Day

-

Color:

-

Customer's Request

-

Carbonization time:

-

6-8 Hours

-

Keywords:

-

Charcoal Making Kiln

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Lanyu

-

Effective Volume:

-

2M3

-

Dimension(L*W*H):

-

2500*1500*2000

-

Voltage:

-

380v

-

Power:

-

5.5

-

Weight (KG):

-

850

-

Raw material:

-

Coconut Shell

-

Name:

-

Airflow Carbonization Furnace

-

Product name:

-

Hardwood Charcoal Carbonization Stove

-

Usage:

-

Biomass Charcoal Directly

-

Advantage:

-

Smokeless

-

Fuel:

-

Firewood

-

Capacity:

-

Day

-

Color:

-

Customer's Request

-

Carbonization time:

-

6-8 Hours

-

Keywords:

-

Charcoal Making Kiln

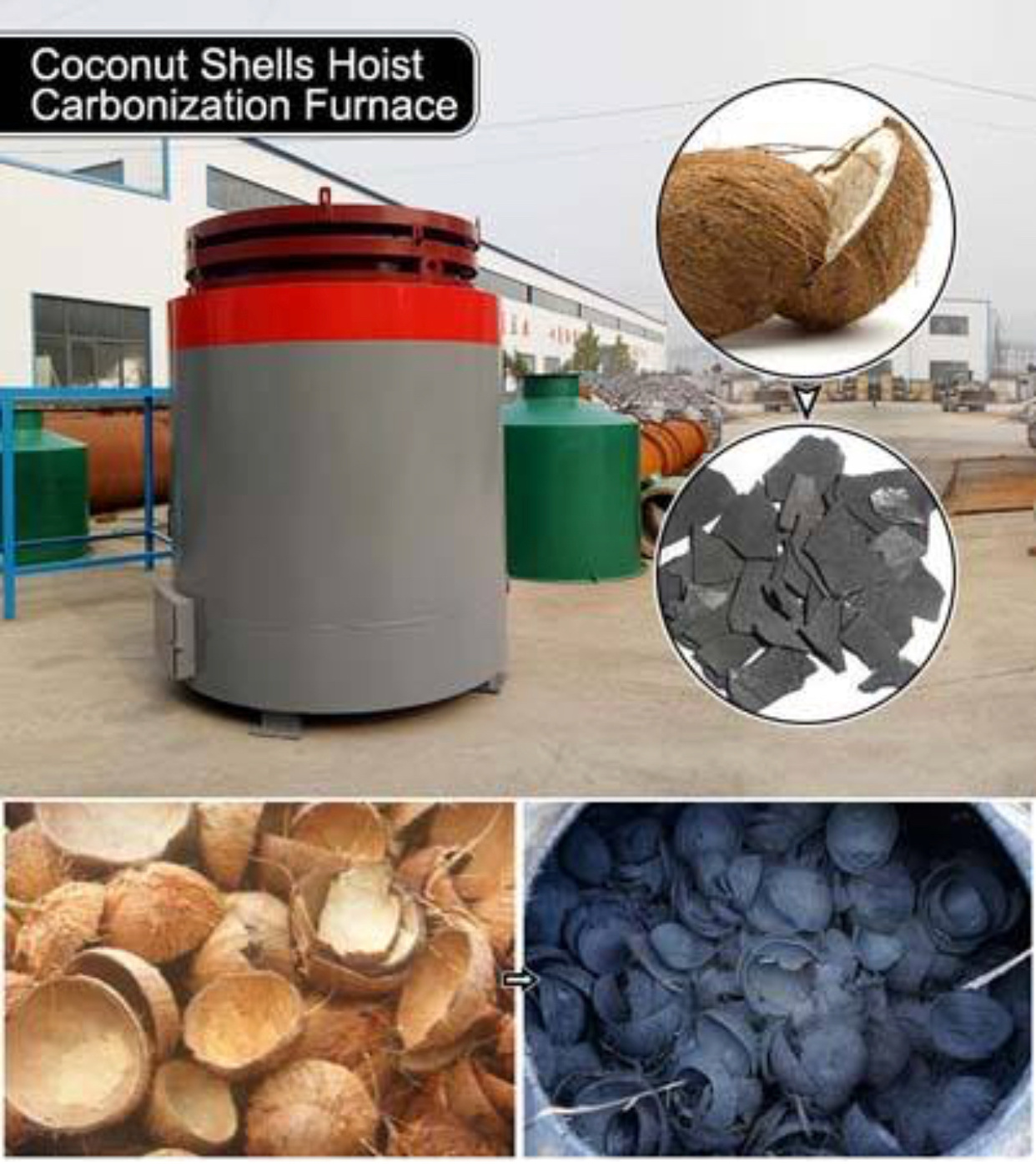

sale charcoal carbonization furnace/charcoal carbonization kiln/carbonization furnace

Carbonization stove (gas flow type) is our newest developed products, and adopt advanced hot air carbonizing processing technology, which greatly increased carbonizing ratio (increased from about 88% to 99%) and shortened the carbonizing time (from 24 hours to 8 hours), and show the features of easy operation, higher safety, high efficiency, energy saving and environment protection.

The fuel can be wood, charcoal,coal, natural gas or diesel,for wood 30-50kg/4-5 hours, if coal about 20-30kg/4-5 hours,natural gas and diesel can be used.we can provide the other four inner pots.

It can achieve carbonization continuously ,after first batch carbonization, you can take out the inner pots to cool them, then put the other four pots inside, start the next batch, so you can carbonization 3 batch 24 hours.

The struture of the air-flow carbonization furnace:

It include the furnace body,furnace cover, heating chamber,inner pot, exhaust shaft four parts. The furnace is made of steel , the thickness of the furnace is 6-8mm, resistant high temperature steel plate,not easy to deformatin and oxidation. the outlet furnace chamber with refractory brick. the thickness of the furnace chamber with refractory brick is 120mm

1.what can be making charcoal?

Almost any biomass can be briquetted,then carbonized Briquetting plants set so far are using Saw Dust, Bamboo dust, Bagasse, Cotton Stalk, Coffee husk, Groundnut Shell, Mustard Husk/Stalk, Pine Needles, Rice Husk, Sugar Mill Waste, Jute waste, Coir pith and other wastes & residues like Castor Shell, Red Gram Stalk, Tobacco stem, Tea Waste, Sander Dust, Tree Bark, Wild Grasses & Shrubs and Sander dust etc. can be also be briquetted individually or in combination without using any binder. And if the raw material larger than 30mm, it can be put the carbonization kiln for carbonizing directly ( The raw material should be very hard)

WOOD CRUSHER MACHINE

SAWDUST DRYER MACHINE

WOOD BRIQUETTE MACHINE

why to make charcoal ?

1. Notable social benefits

Every year large amount of the crop residues such as straw , branches, sawdust, rice hulls, bamboo bits or other debris are discarded,which causes great waste to our society. Now Our equipments can turn these wastes to a kind of new efficient energy --- charcoal, wood tar, etc.. The machine-made charcoal can replace the natural charcoal, meanwhile, protect the forestry resources, and ease the tense situation of current timber industry .

2 Remarkable economic benefits

At present our country’s economy is undergoing a period of rapid development, and the charcoal is in great demand in the fields of industry, agriculture, animal husbandry and civilian industries.In China, the cost of raw materials of making charcoal is generally USD100/ton, but the market price of charcoal is about USD400

800ton, and the exporting price is more than USD600 /ton. Furthermore,the by-products of making charcoal such as wood tar and wood vinegar will bring much more profits.

3.wide use of charcoal

· charcoal in industry: It is mainly used in combining carbon of industrial materials ,metallurgy, and the carburizing carbon of chemical industry.

· Charcoal in agriculture and animal husbandry: It can raise the soil temperature, maintain soil moisture, ,mitigatethe organic fertilizers and improve soil PH.

· Charcoal in life: People often use charcoal heating, barbecue, as well as the fuel used to the tea and tobacco drying.

2. directly way ( put the raw material to the carbonization kiln for carbonizing directly )

specification of the carbonization kiln

. gas flow type carbonization furnace

introduction:

the gas flow type carbonization stove is our new invent, which is also combined type. this kind of carbonization stove are included three inner stove, when one inner stove are finished, it can be hoisted outside,. And when the first inner stove are cooling , the other inner stove can be carbonized at the same time, in this way the cooling time can be reduced much, thus, the productive efficiency increase a lot .This type of stove adopts the structure of unique air storage chamber, to fully reuse the smoke produced during the process of carbonization. And the redundant smoke can be used in drying and carbonizing, saving much fuel during the whole process, and increasing the enterprise revenue.

Pre-sale services:

(1) Advice of model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Lanyu's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.