- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/450V

-

Weight (KG):

-

33000 kg

-

Specification:

-

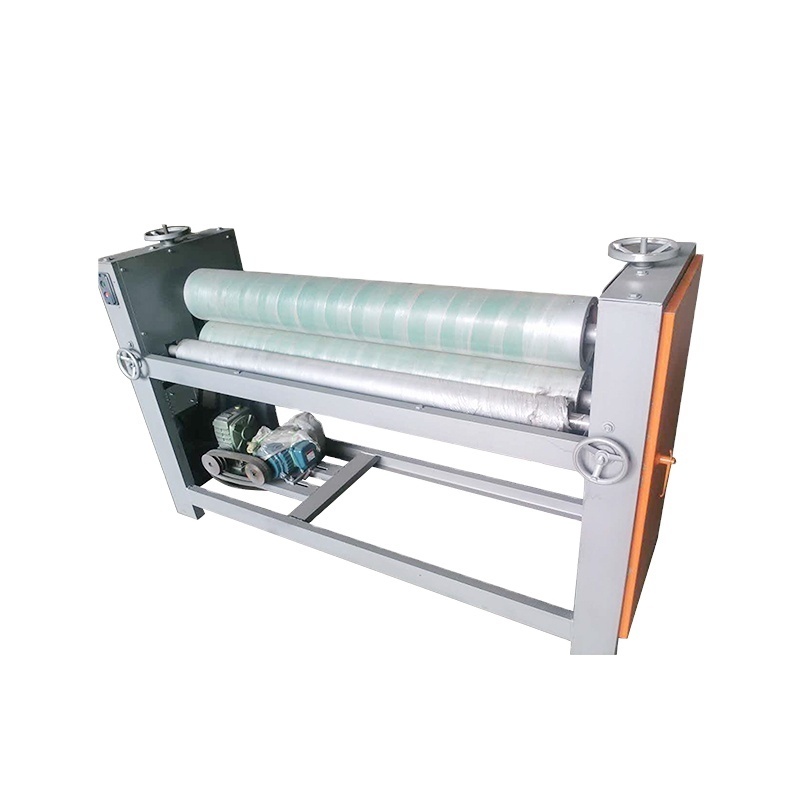

4ft double side glue spreader

-

Quantity of roller:

-

4

-

Glue roller length:

-

1400mmm

-

Rubber roller diameter:

-

245mm\419mm

-

Thickness of rubber:

-

18mm

-

Diameter of steel roller:

-

217mm

-

Rotary speed of roller:

-

45m\min\adjustable

-

Motor power:

-

3-4kw

-

Dimension:

-

2100**1250*1400

-

Weight:

-

1.5ton

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

Plywood Veneer Glue Spreader

-

Brand Name:

-

MLG Machine

-

Voltage:

-

380V/450V

-

Weight (KG):

-

33000 kg

-

Specification:

-

4ft double side glue spreader

-

Quantity of roller:

-

4

-

Glue roller length:

-

1400mmm

-

Rubber roller diameter:

-

245mm\419mm

-

Thickness of rubber:

-

18mm

-

Diameter of steel roller:

-

217mm

-

Rotary speed of roller:

-

45m\min\adjustable

-

Motor power:

-

3-4kw

-

Dimension:

-

2100**1250*1400

-

Weight:

-

1.5ton

Product Parameter

|

Specification

|

4ft double side

glue spreader

|

8ft double side gluing machine

|

8ft pneumatic gluing machine double side

|

|

Quantity of roller

|

4

|

4

|

4

|

|

Glue roller length

|

1400mmm

|

2700 mm

|

2700mm

|

|

Rubber roller diameter

|

245mm/419mm

|

245/419 mm

|

419mm

|

|

Thickness of rubber

|

18 mm

|

20 mm

|

20 mm

|

|

Diameter of steel roller

|

217 mm

|

296 mm

|

296mm

|

|

Hard cromed on surface of steel roller

|

yes

|

yes

|

yes

|

|

Rotary speed of roller

|

45 m/min/adjustable

|

45 m/min/adjustable

|

Adjustable

|

|

Motor power

|

3-4 kw

|

5.5+11

|

7.5+7.5+1.5

|

|

Dimension

|

2100*1250*1400

|

3400*1350*1600

|

|

|

Weight

|

1.5 ton

|

2ton

|

4.6 ton

|

Product Details

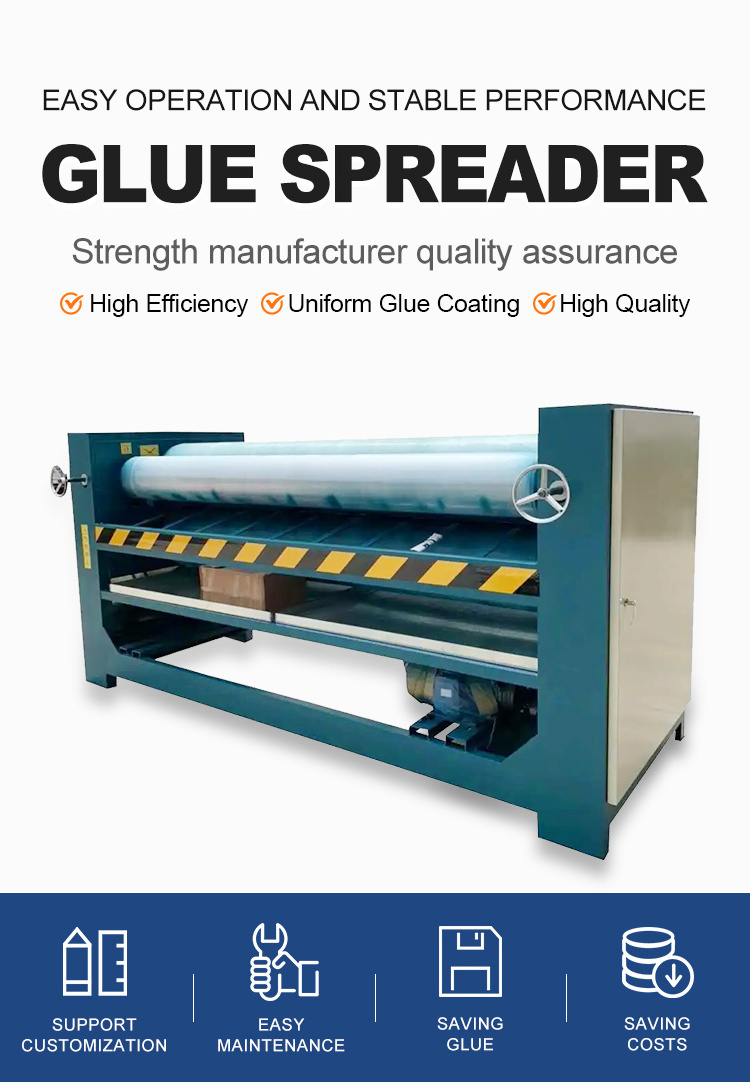

Features:

1.Coated roller with high quality natural rubber with high mechanical strength, hardness suitable, good wear resistance, good aging resistance, long service life.

2.Steel roller with high-quality thick-walled seamless steel pipe, hard chrome plated and uniform, the surface to do mirror

treatment, and then by grinding and other fine processing from Smooth operation, uniform coating, cost savings.

3.The use of the bottom of the hopper design, do not repeatedly add glue, the province of clean labor, a substantial increase in efficiency.

4.Gearbox for the gear, chain mirror with the drive, stable and reliable and durable.

5.The roller speed by the adjustable motor fine-tuning, control and stability.

6.Roller squeeze force balance, the object received rolling pressure uniformity.

7.Repeat the roll of the same roller and roll force.

8.According to the specific needs of the work to roll the speed of adjustment.

2.Steel roller with high-quality thick-walled seamless steel pipe, hard chrome plated and uniform, the surface to do mirror

treatment, and then by grinding and other fine processing from Smooth operation, uniform coating, cost savings.

3.The use of the bottom of the hopper design, do not repeatedly add glue, the province of clean labor, a substantial increase in efficiency.

4.Gearbox for the gear, chain mirror with the drive, stable and reliable and durable.

5.The roller speed by the adjustable motor fine-tuning, control and stability.

6.Roller squeeze force balance, the object received rolling pressure uniformity.

7.Repeat the roll of the same roller and roll force.

8.According to the specific needs of the work to roll the speed of adjustment.

9. the whole machine-wide steel structure, with a door-type shield.

Purpose:

Widely used in plywood factory, furniture factory and sound equipment factory, stickers factory.

Customized Service

Product Recommendation

Professional woodworking machinery manufacturer in China since 1996.

We can supply complete production line equipment, including rotary cutters, peelers, hot presses, dryers, etc. If you have any needs, you can also contact us !

We can design and manufacture any size according to users’ requirements.

Welcome inquiry with details about your product plan.

Welcome inquiry with details about your product plan.

Company Introduction

Shandong Menglianggu Machinery Manufacturing Co., Ltd. was new established in 1996. We have been deeply involved in the wood based panel machinery industry for 20 years, and have many industry equipment design experts.

We focus on the R&D and manufacturing of a full set of wood based panel machinery and equipment, and provide the whole plant planning and design scheme. The main products include a full set of high grade plywood production equipment, automatic particleboard production line and oriented particleboard production line and other industrial equipment.

We will provide you with professional customized service, quality and after sales guarantee. Your satisfaction is the goal we pursue. Thanks for the trust and support from friends all over the world.

We will live up to expectations and strive to move forward. I believe we will become your closest partner.

Customer Feedback

Pre-sale services:

1. Provide the free consultation of the equipment

2. Provide the standard device and the flow chart

3.According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

4.Dedicated personnel are available to entertain and visit the factory

Services during the sales:

1.Strictly inspect the machine before shipment

2.Expatriate personnel teach installation

3.Train the first-line operator.

After-sale services:

1.24 hours online service

2. Provide the VIDEO with Install and debug the equipment

3.Provide remote guidance from professionals

1. Provide the free consultation of the equipment

2. Provide the standard device and the flow chart

3.According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

4.Dedicated personnel are available to entertain and visit the factory

Services during the sales:

1.Strictly inspect the machine before shipment

2.Expatriate personnel teach installation

3.Train the first-line operator.

After-sale services:

1.24 hours online service

2. Provide the VIDEO with Install and debug the equipment

3.Provide remote guidance from professionals

Packing & Delivery

FAQ

1. Can you customize products for clients?

Yes, We can customize and produce woodworking machines according to the customer’s requirements or drawings.

2. How can we trust your factory?

We recommend that you come to our factory to see the goods, to verify the real situation of the products, and know more about our factory.

3.Why does the price often change?

The price depends on the latest prices of the raw materials.

4. What about the contract signing?

If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit. Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

5. How about delivery?

When the product is ready, it can be delivered to you after your full payment. We’ll provide technical guidance.

Yes, We can customize and produce woodworking machines according to the customer’s requirements or drawings.

2. How can we trust your factory?

We recommend that you come to our factory to see the goods, to verify the real situation of the products, and know more about our factory.

3.Why does the price often change?

The price depends on the latest prices of the raw materials.

4. What about the contract signing?

If you’re satisfied with the products and our service, you can sign the contract with us, pay the deposit. Then we’ll produce the machines as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of the products and the accessories are complete.

5. How about delivery?

When the product is ready, it can be delivered to you after your full payment. We’ll provide technical guidance.

Hot Searches