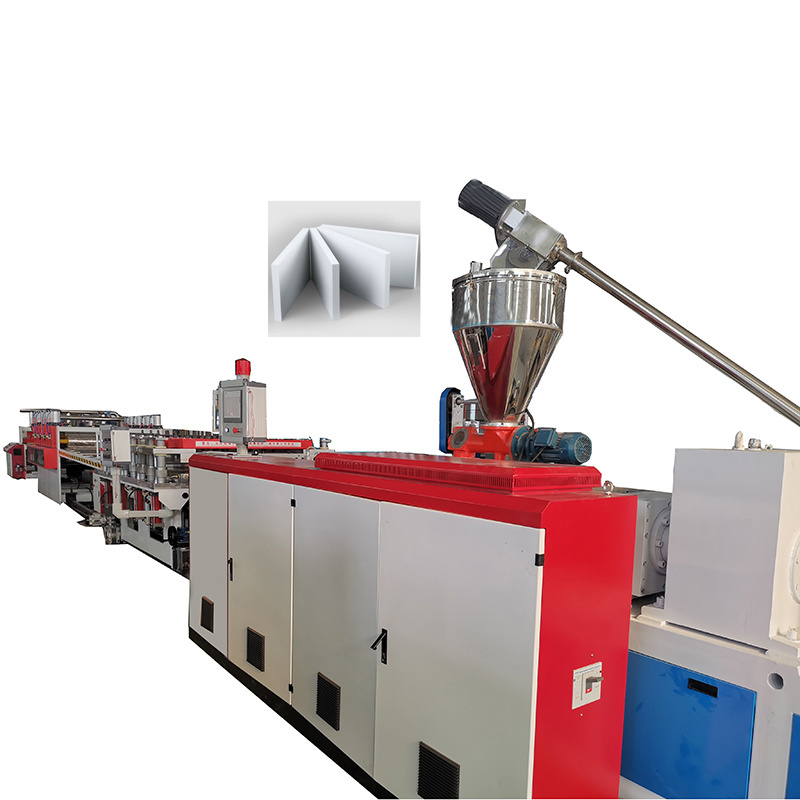

1. Stable, High Output Capacity.

2. ISO SGS CE GOST Certification

3. Famous Brand electric parts: Siemens motor,ABB frequency inverter, Omron temperature controller, Schneider contactor and relay.

4. Long Warranty.