- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

can be customized

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

1200 KG

-

Marketing Type:

-

New Product 2021

-

Product name:

-

Titanium Ore Processing Plant

-

Raw material:

-

mineral ores

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Spare parts supply:

-

Lifelong Provide

-

Factory visit:

-

Welcomed Warmly

-

Recovery rate:

-

80-85%

-

Color:

-

Customized Making

-

Quality:

-

High Reputation

-

Feature:

-

Easy Maintenance\High Effecient

-

After-sales Service:

-

Provided

Quick Details

-

Production Capacity:

-

0-200t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

jxsc/Walker

-

Voltage:

-

can be customized

-

Dimension(L*W*H):

-

depend on the model

-

Weight:

-

1200 KG

-

Marketing Type:

-

New Product 2021

-

Product name:

-

Titanium Ore Processing Plant

-

Raw material:

-

mineral ores

-

Test&Installation:

-

Senior Professional Engineers Assigned

-

Spare parts supply:

-

Lifelong Provide

-

Factory visit:

-

Welcomed Warmly

-

Recovery rate:

-

80-85%

-

Color:

-

Customized Making

-

Quality:

-

High Reputation

-

Feature:

-

Easy Maintenance\High Effecient

-

After-sales Service:

-

Provided

Product Description

Titanium minerals

Titanium minerals are mainly from titanium rock ores and titanium placers. Titanite rock ores are mostly produced in the form of titanomagnetite-ilmenite. Titanium placers, also called titanium sands, are mostly produced in the form of ilmenite-rutile. Most of the titanium sand mines are dominated by ilmenite, and a few are dominated by rutile. At present, most of the world's titanium resources come from titanium rock ore.

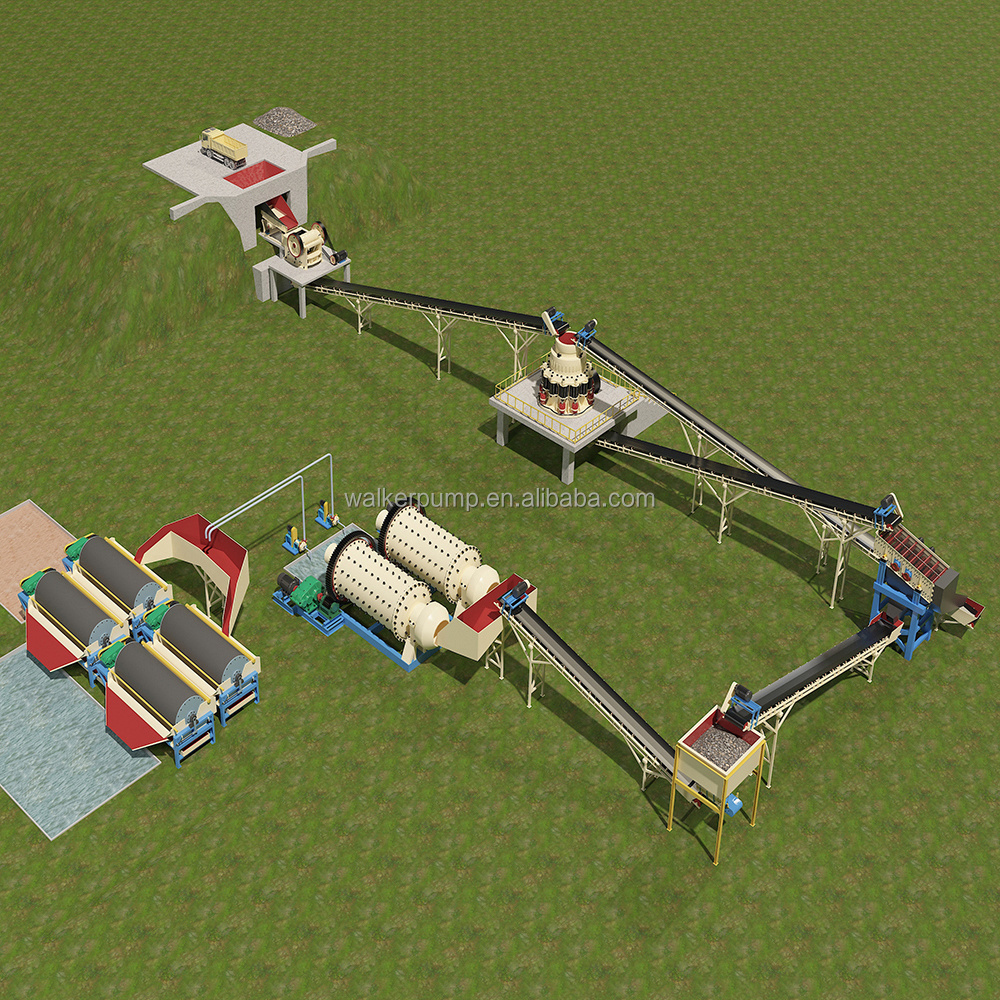

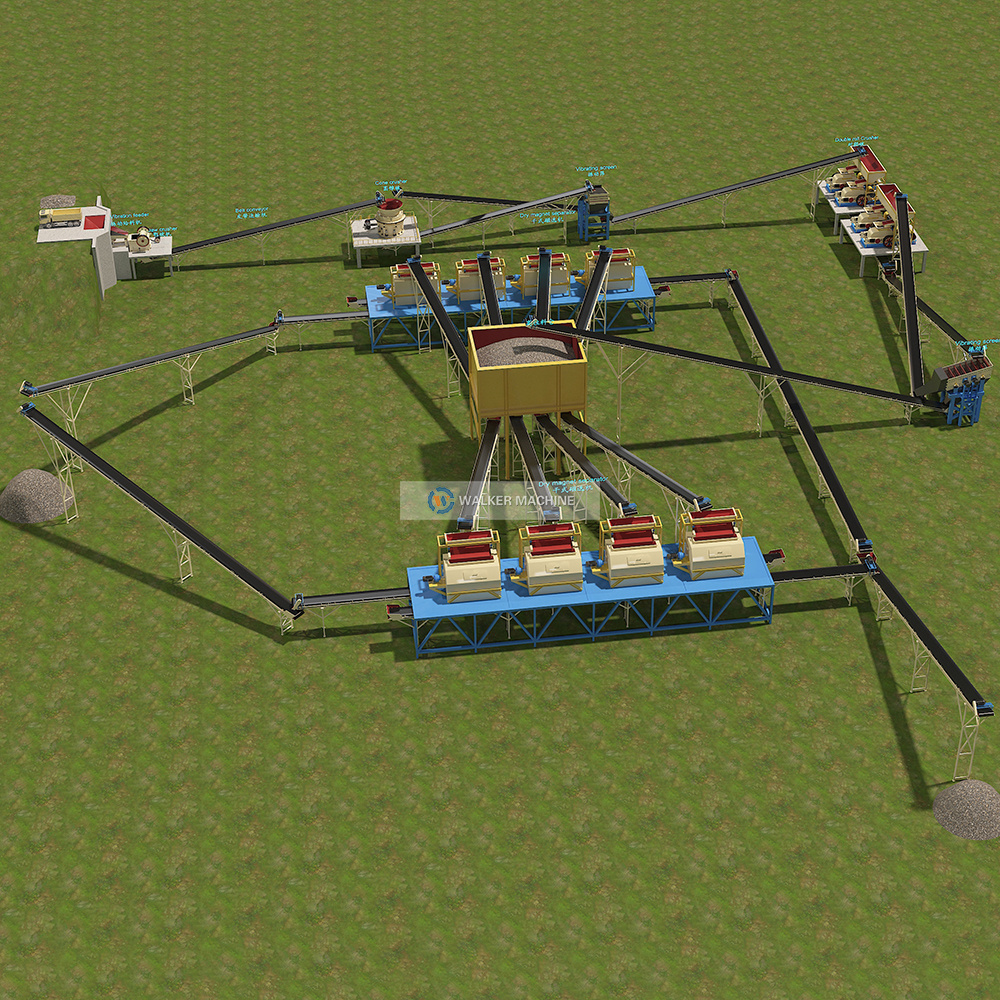

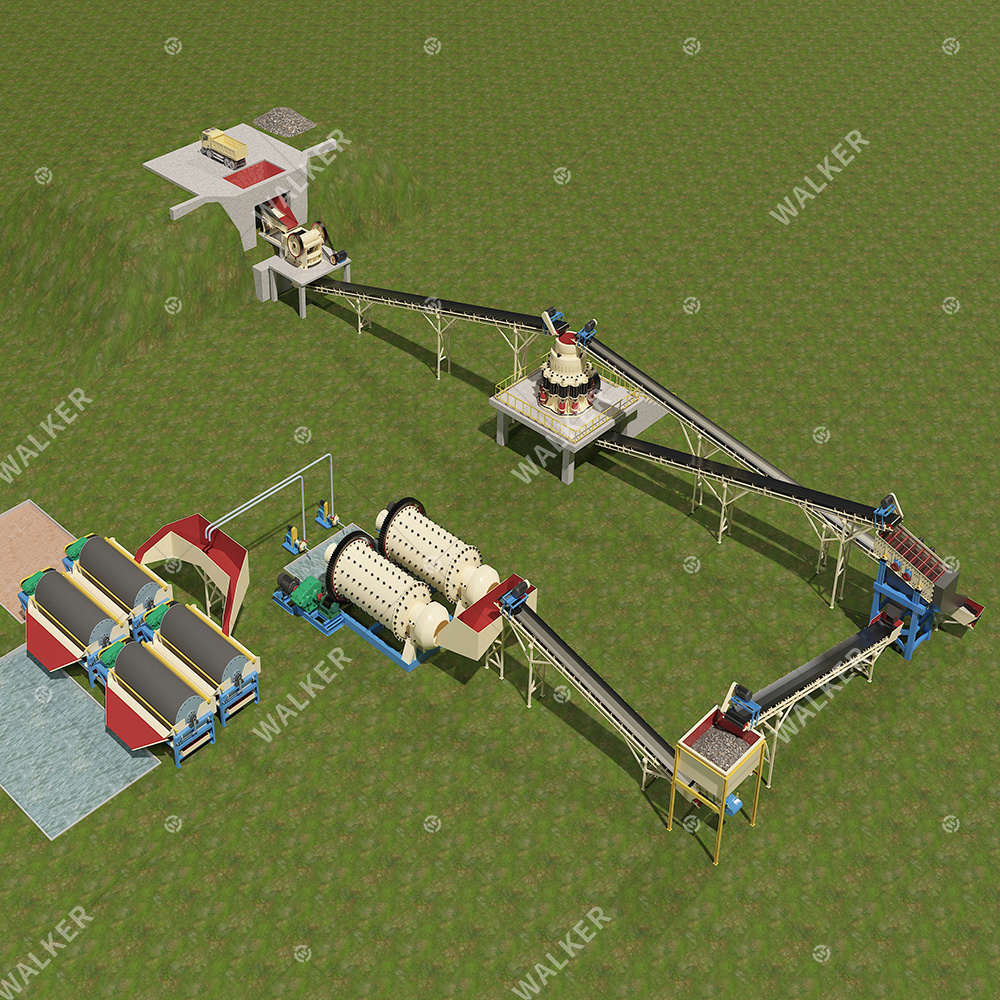

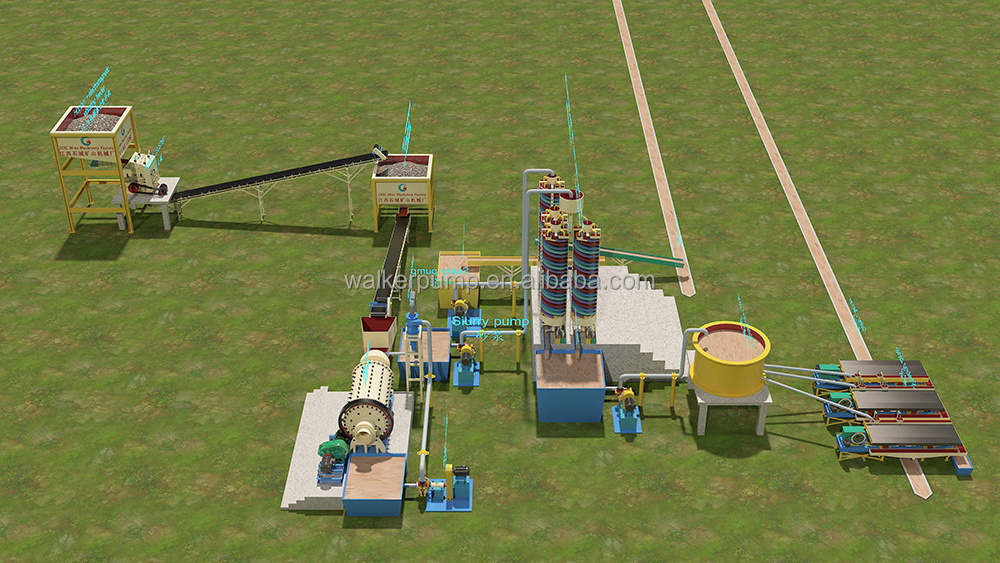

Titanium ore processing plant

An effective titanium ore processing plant mainly includes a comminuting unit (crushing and grinding), a beneficiation unit, and auxiliary equipment.

The most commonly used production equipment is crushers (jaw crushers, cone crushers), ball mills, spiral chutes, magnetic separators, flotation cells, etc.

Titanium crushing production line

The mined titanium ore first goes through a crushing and grinding process to produce powders with uniform particle sizes.

● When crushing, use a jaw crusher for coarse crushing, and then use a cone crusher for fine crushing.

● When grinding, use a ball mill or a rod mill.

As proper grinding fineness is crucial to the flotation results, the particle size of titanium ore generally needs to be ground to less than 0.074 mm for a better flotation effect.

Titanium beneficiation production line

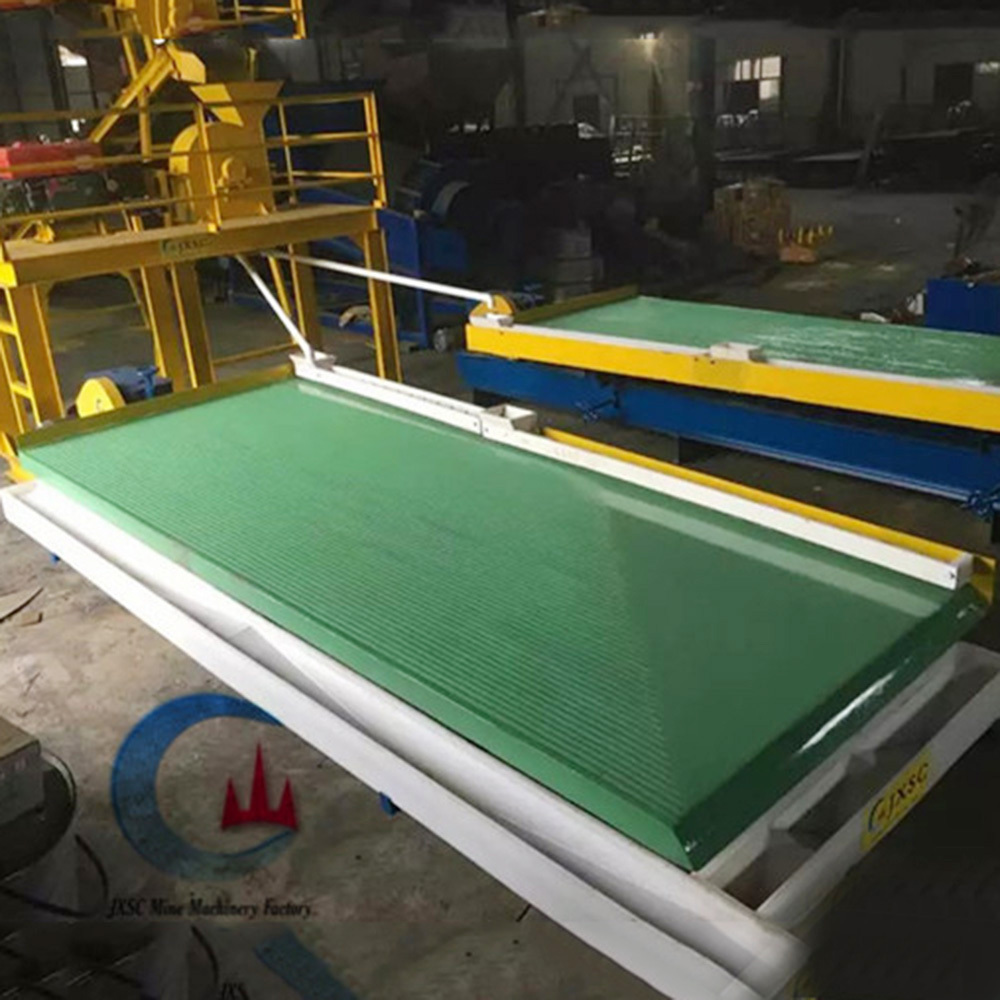

Gravity separation

This method is suitable for the first concentration or pretreatment of crushed titanium ore. By gravity separation, we can separate most of the gangue minerals with a density less than 3g/cm3 from titanium-containing minerals with a density generally greater than 4g/cm3.

Gravity separation machines are jigs,spiral chutes, and shaking tables.

Electrostatic separation

This method mainly uses the difference in conductivity between different minerals in the rough titanium concentrates to further recover titanium minerals. When the rough titanium concentrates contain pyroxene, quartz and other non-conductive minerals, the titanium minerals can be separated by electro-separation.

The electriostatic separators used are roller type, plate type, sieve plate type, and so on.

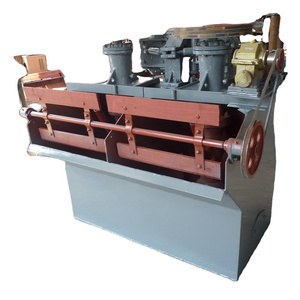

Magnetic separation

This method is mainly used to further concentrate rough titanium concentrates. We often apply low-intensity magnetic separation (LMS) and high gradient magnetic separation (HGMS) to recover titanomagnetite and ilmenite, respectively. This method is also the answer to how we separate titanium from iron.

Magnetic separation equipment mainly includes drum magnetic separators, plate magnetic separators, vertical ring high gradient magnetic separators, etc.

Flotation separation

Flotation is mainly used to separate fine-grained titanium ore. Commonly used flotation reagents are sulfuric acid, tar oil, oleic acid, diesel oil and emulsifier, etc. The beneficiation methods include positive flotation titanium and reverse flotation gangue minerals.

Commonly used flotation equipment is aflotation cell.

Each of the above methods has its own advantages, but the effect is poor when used alone to process titanium rock ore. Therefore, multiple beneficiation methods are often used in combination, and the order of them also depends on the situation.

Main Products

We have professional engineers team to draw flowchart based on customer's stone site details.

We supplied full set

Titanium

processing plant:

Vibrating feeder, jaw crusehr, Jig machine

,

Vibrating screen,

Magnetic Machine

, Flotation Machine,

belt conveyor

.

Successful cases

Packing & Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Company Introduction

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

|

1.Inquiry and consulting support.

2.Ore sample testing support. 3.View our Factory. 4.Design Flowchart. |

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty . 3.Engineers available to service machinery overseas. |

FAQ

●

Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches