- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

11 KG

-

Application:

-

Co2 Laser Cutting Machine

-

Wavelength:

-

1064nm/10.6um

-

Color:

-

blue

-

Quality:

-

High Level

-

Power:

-

150w-500w

-

Usage:

-

Metal & non-metal cutting

-

Cooling:

-

Water-cooling

-

controller:

-

RDC6332M

-

brand:

-

Ruida

-

Height adjustment system:

-

LFS-AM-T43

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Spare Parts Type:

-

Laser parts

-

Brand Name:

-

SZSMT

-

Weight (KG):

-

11 KG

-

Application:

-

Co2 Laser Cutting Machine

-

Wavelength:

-

1064nm/10.6um

-

Color:

-

blue

-

Quality:

-

High Level

-

Power:

-

150w-500w

-

Usage:

-

Metal & non-metal cutting

-

Cooling:

-

Water-cooling

-

controller:

-

RDC6332M

-

brand:

-

Ruida

-

Height adjustment system:

-

LFS-AM-T43

https://www.alibaba.com/product-detail/Auto-Focus-Metal-Non-Metal-Mixed_1600149900695.html?spm=a2747.manage.0.0.723d71d2PhIzz2

Blue Metal & Nonmetal Cutting Head And Ruida RDC6332M LFS-AM-T43 Control System Set For Laser Cutting Machine

1 set including :

1 PCS autofocus CO2 laser metal cutting head

1 SET CO2 laser controller RDC6332M

1 SET LFS-AM-T43 autofocus sensor system

1 SET 2 phase motor (42HS08) and driver (DM556)

1 PCS 5*8mm shaft connector

1 PCS limit switch

3 reflection mirror and 1 focu lens

1 mirror mount

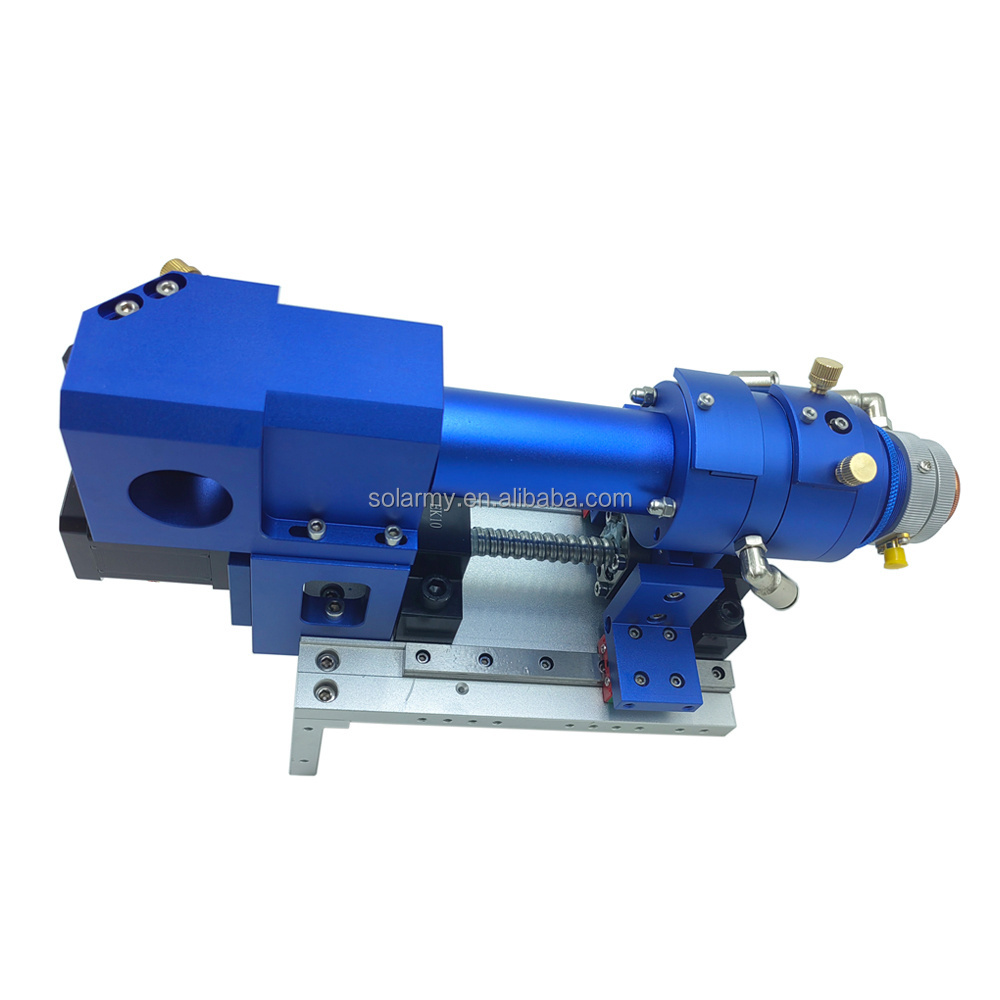

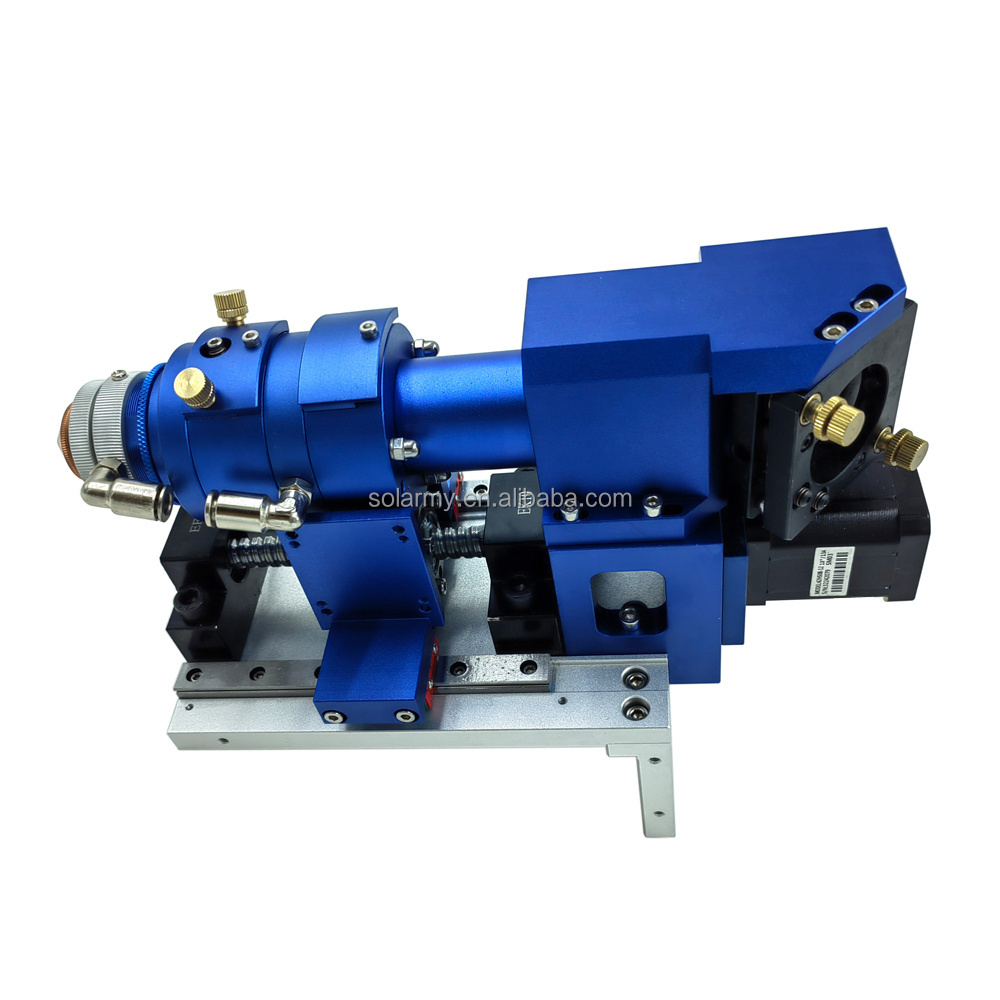

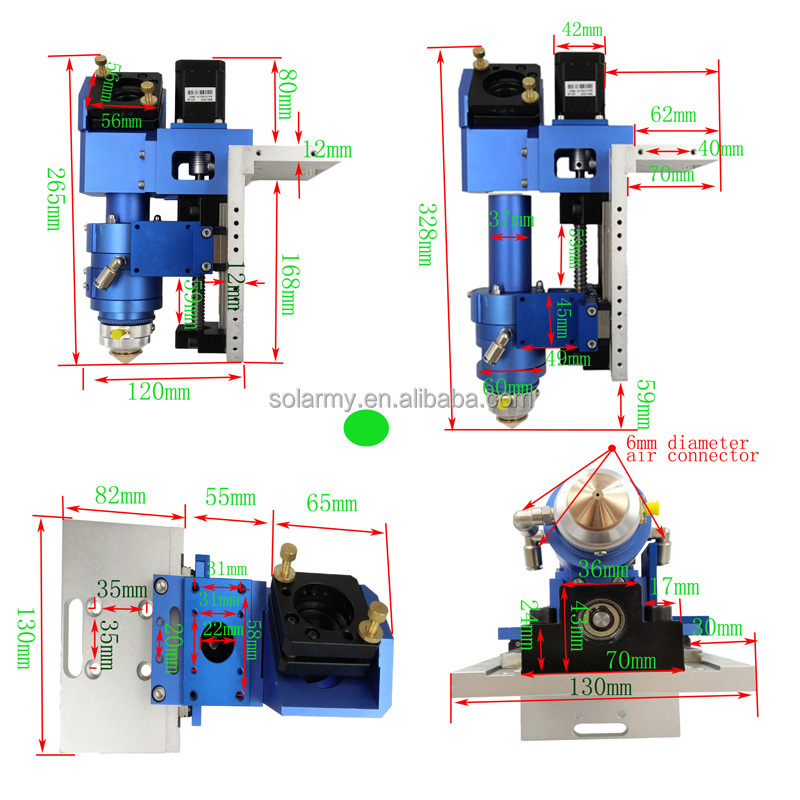

Mixed laser cutting head : Mixed laser cutting head ,

Also known as metal/non-metal laser cutting head , It also call follow-up laser cutting head, I t is s an important part of the metal laser cutting machine . This kind of laser head is different from the ordinary laser cutting head, which can cut metal materials and cut non-metal materials . It is mainly used in medium and low power laser cutting machines below 500W , With the capacitance height adjustment system, the focus position of the metal plate surface can be accurately tracked to accurately cut the metal material.

The mixed laser cutting head has a strong advantage in the application of medium and small power CO2 laser cutting machines, and can support up to 500W of laser power.,With double drawer structure, long and short focal length can cut metal materials or cut non-metal materials.,Focusing mirror air-cooled/water-cooled structure prevents lens overheating and optimizes focus lens mounting drawer,The positive or negative focal length can be adjusted as needed to achieve the best cutting results.

1.P rinciple :

The laser beam enters the cavity of the hybrid cutting laser cutting head through the mirror, and passes through the focusing mirror to concentrate the energy of the laser beam at a certain point, and melts the surrounding material to form processing marks by high temperature to achieve the cutting effect.

The mixed laser cutting head cooperates with the capacitance height adjustment system to move the focusing mirror according to the undulation of the material surface, change the position of the focus, and keep the position of the focus at a certain distance from the board surface, thereby accurately cutting the metal..

2.C omponent

1, Z-axis transmission

2, Three-dimensional mirror bracket

3, Focusing lens cavity

4, C utting nozzle

3.F eature

1.With Z-axis transmission part, it can move up and down to accurately track the focus position.

2. the use of double drawer structure, long and short focal length matching, users can easily replace the focusing mirror of different focal lengths, to achieve the cutting of different materials, do not need to repeatedly check the focus position.

3.Good air tightness and can withstand high gas pressure during metal cutting

4. Conical cutting nozzle is adopted, and the shape of the gas jet is favorable for cutting the metal thin plate.

5.The use of a focusing lens air-cooled/water-cooled structure prevents the lens from overheating.

4.Application industry

It can cut metal materials such as stainless steel, carbon steel, and galvanized sheet, as well as non-metallic materials such as acrylic, MDF, wood, plastic, leather, and cloth.

Mainly used in sheet metal processing, metal advertising word cutting, stainless steel kitchen processing, advertising industry, sheet metal cutting and other industries.

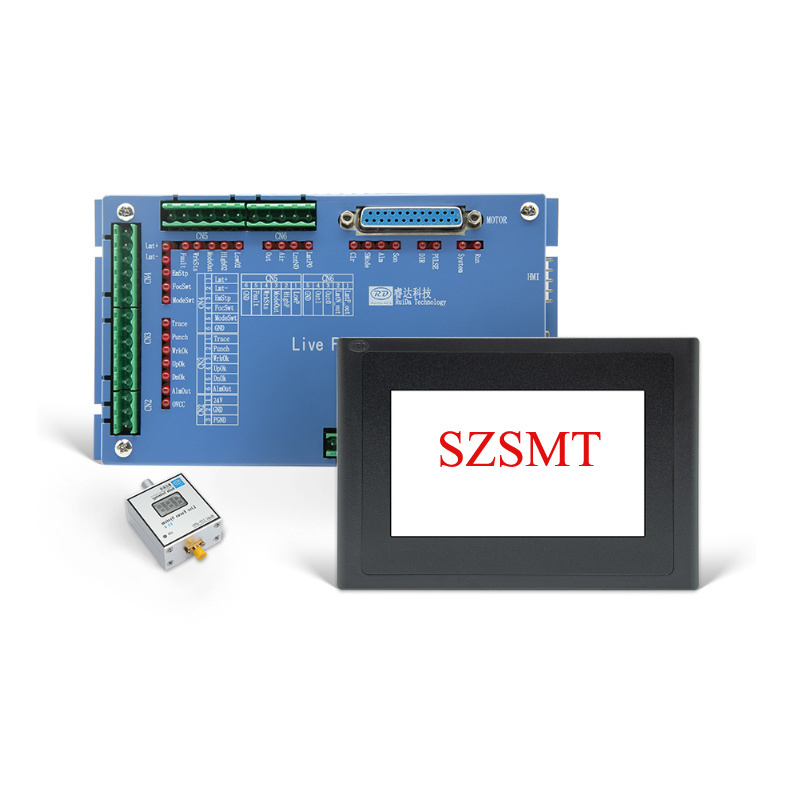

RDC6332M Co2 Laser DSP Controller

Metal and non-metal laser cutting system is based on the RDC6332Mmotion controller .Employed with thin metal plate and non-metal laser cutting techniques, this control system is suitable for non-metal laser cutting and metal laser cutting.

Functions:

System encryption and parameters storage on board, file storage capacity is up to 256M.

Customized boot screen, controller kernel program upgrade remotely

2-way digital/analog laser control interface

Dedicated RF laser control interface

At most 4-axis stepper/servo motor open/closed loop control

Soft/ hard limit coordinates protection for optional

Linear, circular arc and B Spline interpolation

Flexible dedicated LFS interface, supporting many manufactory’s LFS system

Support various metal cutting technology control

Product show