- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Custom Made

-

Weight (T):

-

2 T

-

Power (kW):

-

15

-

Melting Metal Scrap:

-

Aluminum

-

Loading Capacity:

-

500 kgs / Batch

-

Fuel:

-

Natural Gas

-

Feature:

-

Gas Fired Burner Used

-

Color:

-

Support Customized

-

Max temperature:

-

1000°C

-

Crucible Made:

-

Silicon Carbide

-

Certification:

-

ISO9001:2008

-

Advantage:

-

Less Production Time

Quick Details

-

Place of Origin:

-

Haryana, India

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

Indotherm Equipment Corporation

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Custom Made

-

Weight (T):

-

2 T

-

Power (kW):

-

15

-

Melting Metal Scrap:

-

Aluminum

-

Loading Capacity:

-

500 kgs / Batch

-

Fuel:

-

Natural Gas

-

Feature:

-

Gas Fired Burner Used

-

Color:

-

Support Customized

-

Max temperature:

-

1000°C

-

Crucible Made:

-

Silicon Carbide

-

Certification:

-

ISO9001:2008

-

Advantage:

-

Less Production Time

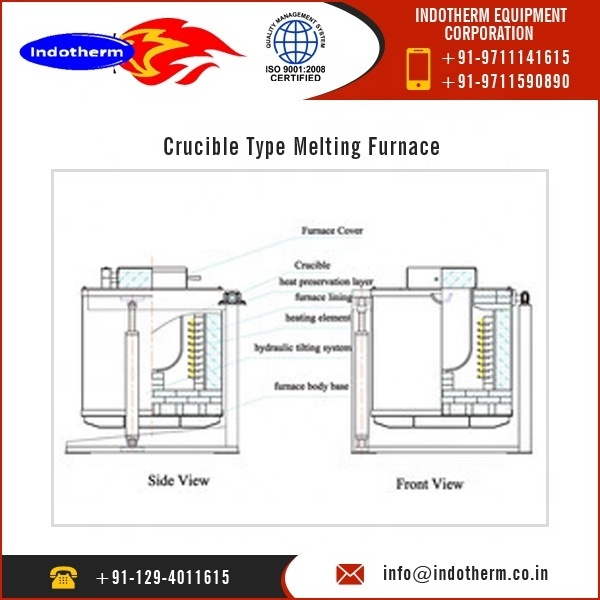

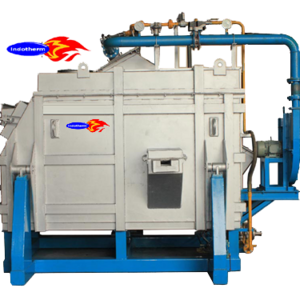

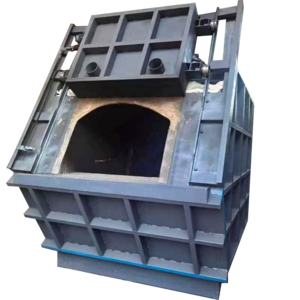

ALUMINIUM MELTING CRUCIBLE FURNACE

Indotherm Equipment Corporation Manufactures Oil/Gas Fired as well as Electrically Heated Crucible Type Aluminum Melting cum holding furnace. Crucible Furnace is used where the quality of the product is considered with utmost importance. These are indirect fired furnaces where the material is being charged in crucible and crucible gets heated directly by Combustion from fuels such as oil, gas or electricity.

APPLICATION:

-

Aluminum Ingot Manufacturing Process.

-

Aluminium Die Casting.

-

Aluminium Sand Casting.

- Aluminium Gravity Casting.

DESIGN FEATURES

-

The furnace can be customized as per customer needs by means of Design, Choice of Fuels, and Metal Tapping (Manual or Hydraulic).

- Furnace Refractory Insulation quality – Skin Temperature less than 50C.

DISTINCT BENEFITS OF Indotherm’s CRUCIBLE TYPE MELTING FURNACE

-

Our Furnace is very safe for the workers / Furnace operators in terms of Oil leakage alarm, Overheating of Metal Alarm.

-

Choice of Fuels as per customers we have heating systems available in (Electrically heated / Fuel fired such as gas or oil).

-

High-Quality Wire Breaded refractory lining eliminating the traditional refractory practices faster head, efficient combustion.

-

The furnace can be equipped with a gear motor or Hydraulic Cylinders for Tilting.

CONSTRUCTION

Furnace Shell is manufactured by High Quality 6-8 mm Carbon steel fabricated construction using plate and rolled sections. The furnace is insulated with high-temperature refractory, backed with ceramic insulating board and calcium silicate solution.

TEMPERATURE CONTROL

The provision of maintaining the temperature has been provided in the furnace. Concept temperature control is by sensing molten metal temperature through thermocouple and indicator panel.

BURNER

The North American style multiple-stage type burners is complete with automatically operated flame sensing ignition rod, electric ignition safe and reliable operation. The burner, when not operating, is protected against radiant heat from refractory by a thermostat activating the fan to maintain burner internals within acceptable temperature limits.

Electric Resistance Furnace: making no compromise in part of refractory insulation, our heating elements are designed in-house with wire alloys such as kanthal, nichrome, or Silicon carbide rods. Option of silicon carbide heaters can be supplied and heaters can be replaced without removal of the crucible.

Technical Design of Indotherm Models but with the Following Features

The heat exchanger in the exhaust gas duct to preheat the combustion air for the burners

Energy savings of up to 25 % in comparison to other fuel-heated melting furnaces featuring sidewall exhaust gas vents

- Side exhaust gas discharge.

- Low burn-off provides for high-quality melt.

- Low hydrogen absorption by the melt.

- Low heat exposure for the operator in the area above the crucible.

- Max. furnace temperature of 1100 °C for melt bath temperatures up to 950 °C.

- Required minimum gas pressure at full load: 80 mbar.

|

Model

KGS |

Tmax Melt °C |

Crucible |

Capacity Kgs /hr |

Burner Output (Kwh) |

Melting performance Kgs/hr |

Consumption Melting M3/hr |

Consumption Holding Lid closed |

Outer dimensions Ø x h |

Shipping Weight |

|

200 |

1200 |

TP 287 |

180 |

300 |

150 |

1,3-1,5 |

10 |

2800 x 1800 |

2100 |

|

350 |

1200 |

TP 412 |

330 |

300 |

220 |

1,3-1,5 |

11 |

2830 x 2000 |

2600 |

|

400 |

1200 |

TP 412 |

370 |

300 |

240 |

1,3-1,5 |

26 |

3120 x 2200 |

3000 |

|

600 |

1200 |

TP 587 |

570 |

390 |

400 |

1,3-1,5 |

17 |

3170 x 2350 |

3400 |

|

1000 |

1200 |

TB 800 |

1000 |

450 |

450 |

1,3-1,5 |

19 |

3200 x 2500 |

3650 |

| Crucible Type Melting Furnace | |

| Fuel Consumption | 0.5Kw/Kg for melting at 720C Tap out temperature.12 Kw/Hr for Holding. |

| Capacity | 100 Kgs – 500 Kgs per Batch. |

| Charging | Manual. |

| Metal Tapping | Manually or Hydraulic Tilting via Furnace Launder. |

| Fuels | PNG/LPG/Propane. |

Since its establishment in 1991, Indotherm Equipment Corporation has focused on manufacturing, exporting, and supplying high-standard furnaces and belt conveyors. As an ISO 9001:2008 certified firm, our product range includes Crucible Furnace, Rotary Furnace, Hydraulic Tilting Furnaces, Reverberatory Furnaces, and Tilting Reverberatory Furnaces. Our primary objective is to provide products that prioritize safety and environmental friendliness, with a notable emphasis on energy-saving capabilities and reduced fuel consumption.

To ensure product quality, we maintain a directory of authorized vendors and conduct thorough research to select reliable suppliers. The raw materials undergo stringent quality checks by both the vendors and our own quality tests, ensuring compliance with industry standards. Our commitment to quality has garnered praise from clients, enabling us to establish a strong market position based on exceptional service and top-notch products.

Equipped with cutting-edge machinery, our packaging unit ensures secure export and delivery of products worldwide. Our dedicated team stays updated with the latest technology, enabling us to deliver high-class products. Under the guidance of Mr. C. L. Tripathi, who prioritizes customer satisfaction and environmental safety, we continuously strive to deliver superior, energy-efficient products. Indotherm Equipment Corporation is committed to providing high-quality products, advancing the aluminum industry, and maintaining customer satisfaction.

Overall, Indotherm Equipment Corporation is dedicated to delivering high-quality products, maintaining customer satisfaction, and contributing to the advancement of the aluminum industry.