- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MAP

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

90 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product Name:

-

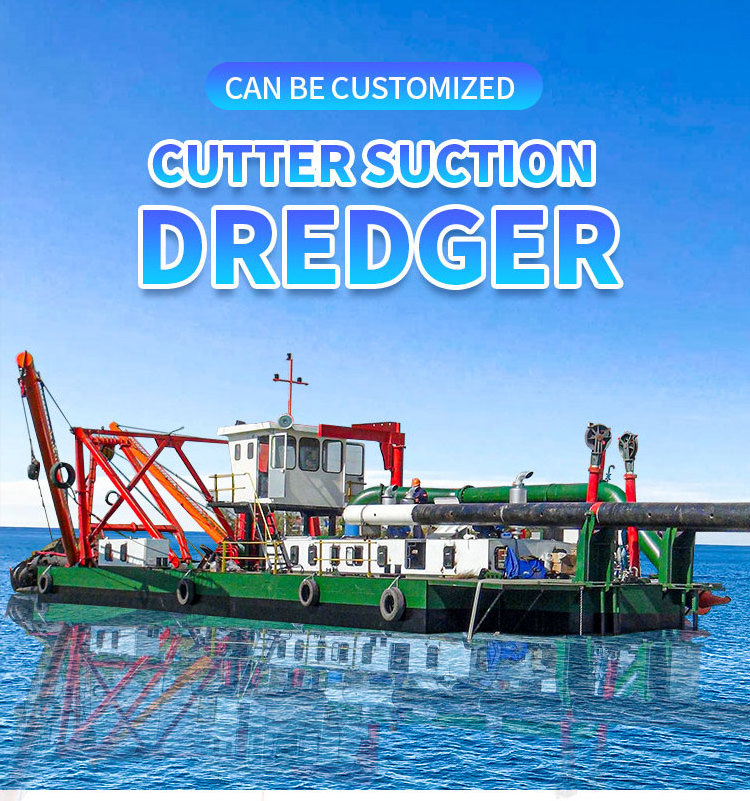

2018 Hot newest cutter suction dredgers For sale

-

Application:

-

Sand Dredging

-

Color:

-

Customer's Request

-

Structure:

-

Dismountable Installation

-

Working capacity:

-

100m3

-

Keywords:

-

High Gold Recovery Rate

-

Name:

-

Sand Pump Suction Dredger

-

Usage:

-

Port River Lake Sea

Quick Details

-

Dredging Depth:

-

45 m

-

Draught:

-

14 inch

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MAP

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

90 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product Name:

-

2018 Hot newest cutter suction dredgers For sale

-

Application:

-

Sand Dredging

-

Color:

-

Customer's Request

-

Structure:

-

Dismountable Installation

-

Working capacity:

-

100m3

-

Keywords:

-

High Gold Recovery Rate

-

Name:

-

Sand Pump Suction Dredger

-

Usage:

-

Port River Lake Sea

2022 Hot Newest Small 1200m3 Cutter Suction Dredger Manufacturer Sand Pump Suction Dredger Sand Dredging High Gold Recovery Rate

We can manufacture dredger according to customer requirements. Different size and equipments, etc. All the dredgers have to be tested before delivery, make sure fast-assembly in clients working site.

A. Equipment arrangement

1) Cutter

2) Cutter Ladder and Suction pipe

3) Ladder

4) Swing winches (2 sets)

5) Ladder winch (1 set)

6) Operating cabin

7) Harbor diesel engine generator set

8) Deck crane

9) Dredge pump

10) Gearbox

11) Main diesel engine

12) Auxiliary diesel engine

13) Generator and high pressure hydraulic pump, emergency hydraulic pump

14) Spuds and spud hoisting rams ( each 2 sets )

Operating room equipped on the dredger

15) Operating room is located in the front of the main deck; its size is according to the dredger’s inches.

16) The operating room has two doors, two fixed windows and two adjustable windows. Controlling room arrangement

17) One height adjustable swivel chair

18) Two controlling platforms, one engine room for controlling boxes.

2. Overview

The dredger is a not self-propulsion, hydraulic cutter suction dredger. The pontoon part is made up of several boxes. The dredger

equipments include sideslip device, cutter up and down device, location spud device, deck crane and so on. The main engine is an

independent entrainment form, one main pump engine, one auxiliary hydraulic engine. Dredger pump host output belt has clutch reduction function.Dredger pump is driven by the main gear decelerating box.Lighting and emergency power for stopping working will be offered by the generator set.Cutter will be driven by the motor and cutter bearing with lubricating sealing device.Hydraulic pump will be driven by the gear box through auxiliary engine

3. Work condition & standard

3.1 Work condition

------The Maximum Temperature 50℃

------The Minimum Temperature -10℃

------The Minimum Temperature -10℃

------The Maximum Temperature of The Cabin 55℃

------The Maximum Temperature of The River (Sea) Water 35℃

------The Relative Humidity ≤80%

3.2 Appropriate working area Coastal waters and the following of dredging, desilting, dredging sand.

3.3 Appropriate soil texture:

Dredging soil and iron sand with Level Ⅲ as well as lower than Ⅲ

Product Advantages

• The innovative jib system adopts embedded block, plug-in boom head and international advanced U section jib, which has excellent lifting performance and safe and reliable lifting work.

• The unique stretch and retract technique avoids the bend of the core pipe and cylinder and the break of the boom caused by misoperation, improving the safety of the operations.

• Eight patent techniques ensure the smooth, high efficiency and energy conservation of the lifting, rotation, and luffing systems.

• The torque limiter adopts colorful LCD display, realizing the intelligence of the failure diagnosis. The precision is ahead of the industry.

• Adopt the new hydraulic motor with big torque starting point, making the secondary lifting safer.

• The humanity design makes the cab and control cab more spacious, and easy to operate.

• Six unique manufacturing technologies ensure the high quality.

• The working condition expands twice. Newly add 5t counterweight.

A. Equipment arrangement

1) Cutter

2) Cutter Ladder and Suction pipe

3) Ladder

4) Swing winches (2 sets)

5) Ladder winch (1 set)

6) Operating cabin

7) Harbor diesel engine generator set

8) Deck crane

9) Dredge pump

10) Gearbox

11) Main diesel engine

12) Auxiliary diesel engine

13) Generator and high pressure hydraulic pump, emergency hydraulic pump

14) Spuds and spud hoisting rams ( each 2 sets )

Operating room equipped on the dredger

15) Operating room is located in the front of the main deck; its size is according to the dredger’s inches.

16) The operating room has two doors, two fixed windows and two adjustable windows. Controlling room arrangement

17) One height adjustable swivel chair

18) Two controlling platforms, one engine room for controlling boxes.

2. Overview

The dredger is a not self-propulsion, hydraulic cutter suction dredger. The pontoon part is made up of several boxes. The dredger

equipments include sideslip device, cutter up and down device, location spud device, deck crane and so on. The main engine is an

independent entrainment form, one main pump engine, one auxiliary hydraulic engine. Dredger pump host output belt has clutch reduction function.Dredger pump is driven by the main gear decelerating box.Lighting and emergency power for stopping working will be offered by the generator set.Cutter will be driven by the motor and cutter bearing with lubricating sealing device.Hydraulic pump will be driven by the gear box through auxiliary engine

3. Work condition & standard

3.1 Work condition

------The Maximum Temperature 50℃

------The Minimum Temperature -10℃

------The Minimum Temperature -10℃

------The Maximum Temperature of The Cabin 55℃

------The Maximum Temperature of The River (Sea) Water 35℃

------The Relative Humidity ≤80%

3.2 Appropriate working area Coastal waters and the following of dredging, desilting, dredging sand.

3.3 Appropriate soil texture:

Dredging soil and iron sand with Level Ⅲ as well as lower than Ⅲ

Product Advantages

• The innovative jib system adopts embedded block, plug-in boom head and international advanced U section jib, which has excellent lifting performance and safe and reliable lifting work.

• The unique stretch and retract technique avoids the bend of the core pipe and cylinder and the break of the boom caused by misoperation, improving the safety of the operations.

• Eight patent techniques ensure the smooth, high efficiency and energy conservation of the lifting, rotation, and luffing systems.

• The torque limiter adopts colorful LCD display, realizing the intelligence of the failure diagnosis. The precision is ahead of the industry.

• Adopt the new hydraulic motor with big torque starting point, making the secondary lifting safer.

• The humanity design makes the cab and control cab more spacious, and easy to operate.

• Six unique manufacturing technologies ensure the high quality.

• The working condition expands twice. Newly add 5t counterweight.

|

Dredger LOA

|

30.0m

|

|

Hull size(L×B×H)

|

19.0×7.5×2.0m

|

|

Main pontoon(L×B×H)

|

13.8×3.5×2.0m

|

|

Side pontoon (L×B×H)

|

19.0×2.0×2.0m

|

|

Structure

|

Can be dismantle and re-assemble easily ,box structure, lower delivery cost

|

|

Main engine brand & power

|

Cummins /477kw

|

|

Auxiliary engine brand& power

|

Cummins/224kw

|

|

Harbour generator

|

30GF/Cummins

|

|

Dredging pump

|

|

|

Discharge pipe inner Dia..

|

350mm

|

|

Head

|

45m

|

|

Max. dredging depth

|

11m

|

|

Water flow

|

1200m³/h

|

|

Solid sand capacity

|

250m³-300m³/h

|

|

Discharge distance

|

1500m

|

|

Cutter head Dia.

|

1450mm

|

|

Cutter power

|

70kw

|

|

Draught

|

1.4m

|

|

Displacement

|

174T

|

|

Hydraulic control system

|

PLC Siemens

|

|

Wire rope pulling force (Lifting winch )*Quantity

|

80KN *1

|

|

Wire rope pulling force (Traversing winch )*Quantity

|

80KN *2

|

|

Operation room

|

Adjustable chair, movable side-window, air condition, PLC system, signal lights and floodlights

|

|

Total weight

|

90T

|

|

Total power

|

731kw

|

|

Total fuel oil consumption

|

105L/H

|

Weifang MAP Import & Export Co., Ltd. was established in 2006. Our factory with staff number of 100 persons, among them 20 are technical engineers,20 are professional sales persons and after-sales service persons. We have been set up our own research institute.

We are manufacturer for site dumper wheel loaders backhoe loader disc mowers tractor with front end loaders and etc.

We have excellent teams who focus on product development &design, quality control & inspection and company running. In order to supply the satisfactory products and services, we have built a modern quality management system which is in strict accordance with international standards.

Will continue to take high quality, low cost and globalization as its strategic goals, integrate innovation, and create a world-class brand and the world's most competitive engineering machinery, agricultural equipment manufacturing base.

Now the production capacity of our factory is 1000 units per year. At present, some of products have passsed CE certification and ISO9001 quality system.

We have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. We warmly welcome customers from at home and abroad to cooperate with us. We are looking forward to receiving your inquiries.

1.How can I place order?

A: You can contact us by email about your order details, or place order on line.

2.How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T or start order from Alibaba trade assurance.

3.Are you factory supplier?

A: Yes, we are real factory supplier for over 17 years, own a super technical team to serve adjusting design for customers.

4.Which brand engine do you have for site dumpers?

A: We company choose good quality engine for site dumpers, Changchai, Xichai, Weichai Power engine/ cummins engine/ Deutz diesel engine and so on optional.

5.What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you a Pl for your confirmation. You will be requested to do prepaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15 days if we don't have the iterms in stock. Before production has been finished, we will contact you for shipment dletails, and the balance payment. After payment has been settled. we start to prepare the shipment for you.

More details please ask us online or send inquiry to us, we will answer first

time.

Hot Searches