- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1kg

-

Size:

-

40*40*120cm

-

Weight (KG):

-

20 kg

-

Application:

-

pure water or waste water

-

Flow Rate:

-

10-50000000 liter/hour

-

Max.Pressure:

-

10 bar

-

Lamp Life:

-

9000 hours

-

Voltage:

-

110V/220V/380V/440V

-

Working Temperature:

-

5℃~60℃

-

Type:

-

Tube, Close channel

-

Certification:

-

CE/ISO

-

Lamp:

-

HatChee

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HatChee

-

Material:

-

Carton, SS304, SS316L

-

Weight:

-

1kg

-

Size:

-

40*40*120cm

-

Weight (KG):

-

20 kg

-

Application:

-

pure water or waste water

-

Flow Rate:

-

10-50000000 liter/hour

-

Max.Pressure:

-

10 bar

-

Lamp Life:

-

9000 hours

-

Voltage:

-

110V/220V/380V/440V

-

Working Temperature:

-

5℃~60℃

-

Type:

-

Tube, Close channel

-

Certification:

-

CE/ISO

-

Lamp:

-

HatChee

UV Sterilization Equipment

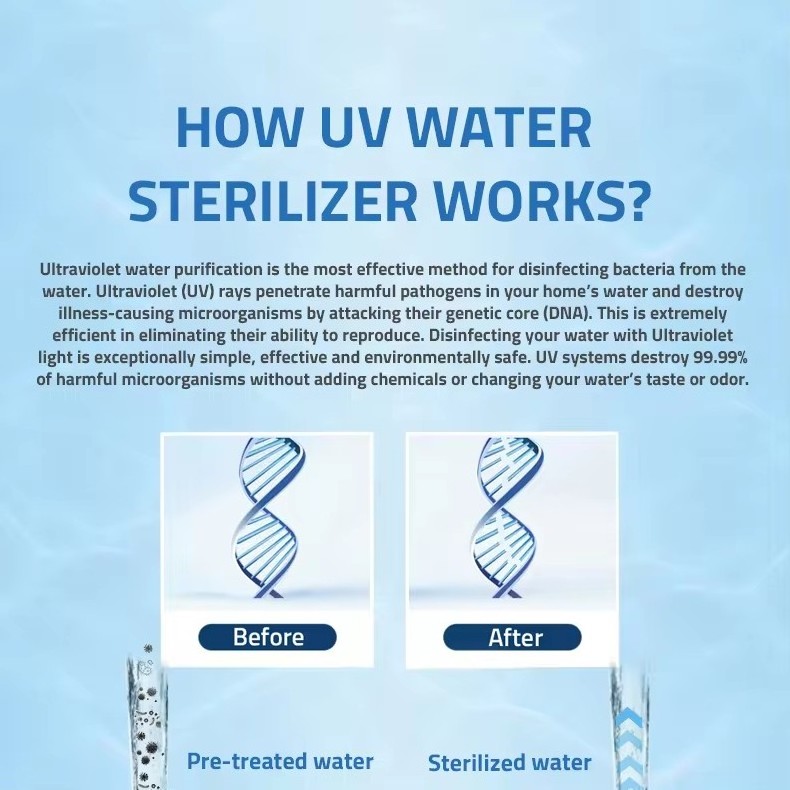

Disinfection principle of ultraviolet sterilizer

Ultraviolet rays can be divided into three wavelength bands according to their biological functions: UV-A (320-400nm), UV-B (275-320nm), UV-C (200-275nm) and vacuum ultraviolet rays. In water treatment, the UV-C band of ultraviolet rays is actually used. In this band, ultraviolet light with a wavelength near 260nm has been identified as the effective band of ultraviolet rays with the highest sterilization efficiency.

UV sterilizer integrates comprehensive sciences such as optics, microbiology, mechanics, chemistry, electronics, and fluid mechanics. Imported and high-quality domestic high-efficiency, high-intensity and long-life UV-C ultraviolet light generators are used to irradiate the flowing water with UV-C ultraviolet light. When bacteria, viruses, etc. in the water are irradiated by a sufficient dose of UV-C ultraviolet light (wavelength 253.7nm). Its cell DNA and cell structure are destroyed, and cell regeneration cannot proceed, so as to achieve the effect of water disinfection and purification. Ultraviolet light with a wavelength of 185nm can also decompose organic molecules in water, generate hydrogen radicals and oxidize organic molecules in water to CO2 and H2O, and achieve the effect of removing TOC.

Advantages of UV disinfection equipment

Efficient sterilization rate: The sterilization rate of ultraviolet rays on bacteria and viruses can reach 99%-99.9% in one to two seconds.

Broad-spectrum sterilization: The broad-spectrum sterilization of ultraviolet rays is the highest at present, and it has a high-efficiency killing effect on almost all bacteria and viruses.

No secondary pollution: Ultraviolet sterilization does not need to add any chemicals, so it will not cause secondary pollution to water bodies and the surrounding environment. Does not change any components in the water.

Safety and environmental protection: The traditional disinfection technology uses chloride or stinky fluorine, and the disinfectant itself is a highly toxic and flammable substance. The ultraviolet disinfection system does not have such a safety hazard.

Low cost: Ultraviolet sterilizing equipment has the advantages of small footprint, easy installation, low operating cost, and small total investment. The operating cost is 1/2 of that of chlorine disinfection.

Features of UV sterilizer disinfection equipment

Imported lamp: high efficiency, long life

The equipment adopts imported lightsources/Philips ultraviolet lamps, which have high-intensity output, high conversion rate, long life, good reliability, and good continuous sterilization and disinfection effect

Professional customized ballast: stable performance and high matching

The electronic ballast used in the equipment is specially produced and customized for this product. It has the characteristics of strong adaptability, high matching, long life and complete protection functions.

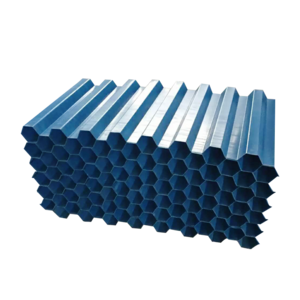

Imported material quartz casing: high purple penetration rate, high sterilization rate

The casing is pure imported raw material quartz from the Pacific Ocean, which has good matching and high purple transmission rate (ultraviolet transmission rate is above 93%)

Big brand pharmaceutical (food) grade 316 (304) stainless steel raw material

The product adopts custom-made plates and pipes, and the main components are all laser blanked, drilled, and cut. The product has uniformity, consistency, interchangeability, aesthetics, high precision, and small error. It is easy to install, fast and efficient. , save time, effort, and labor

Factors Affecting Ultraviolet Germicidal Effect

Ultraviolet transmittance (UVT)

An important factor affecting the effect of ultraviolet sterilization is the ultraviolet transmission rate (UVTransmission) or medium absorption rate (Absorbance) of the sterilization medium (water). The transmittance of ultraviolet rays and the absorptivity of the medium are affected by factors such as dissolved organic matter, inorganic matter, and undissolved suspended matter in water.

Total suspended particles (TSS)

The effect of suspended particles on the sterilization effect of ultraviolet rays is also very obvious. Suspended particles can absorb and reflect ultraviolet rays, thereby preventing ultraviolet rays from reaching the DNA of bacteria and viruses. In addition, suspended particles will also accelerate the scaling and pollution of the quartz sleeve, thereby affecting the sterilization effect.

particle size

The size of the particles in the water has a great influence on the sterilizing effect of ultraviolet rays, because large suspended particles will form shadows and dead angles that protect bacteria and viruses. Generally, the effluent from the secondary sedimentation tank is more beneficial to ultraviolet sterilization, and the average size of suspended particles in the water should be less than 30um.

Exposure time

Exposure time is related to traffic. The UV system is generally designed according to the peak DC flow rate. The smaller the flow rate, the longer the exposure time, and the greater the effective dose of the system.

The effect of ultraviolet rays on the inactivation of microorganisms in water

|

Type |

Name |

100% kill time (s) |

Type |

Name |

100% kill time (s) |

|

Bacteria |

Bacillus anthracis |

0.30 |

Bacteria |

Tuberculosis (Mycobacterium) |

0.41 |

|

diphtheria |

0.25 |

Vibrio cholerae |

0.64 |

||

|

Clostridium tetani |

0.33 |

Pseudomonas |

0.37 |

||

|

Clostridium botulinum |

0.80 |

Salmonella |

0.51 |

||

|

Shigella |

0.15 |

Enterobacteriaceae |

0.41 |

||

|

Escherichia coli |

0.36 |

Typhimurium |

0.53 |

||

|

Viruses |

Adenovirus |

0.10 |

Viruses |

flu virus |

0.23 |

|

Phage virus |

0.20 |

Poliovirus |

0.80 |

||

|

coxsackie virus |

0.08 |

Rotavirus |

0.52 |

||

|

ECO virus |

0.73 |

tobacco mosaic virus |

16 |

||

|

Echovirus type I |

0.75 |

Hepatitis B virus |

0.73 |

||

|

Mold Spores |

Aspergillus niger |

6.67 |

Mold Spores |

soft spores |

0.33 |

|

Aspergillus |

0.73-8.80 |

Penicillium |

2.93-0.87 |

||

|

coprophagal fungus |

8.0 |

Penicillium toxigenicum |

2.0-3.33 |

||

|

Mucor |

0.23-4.67 |

Penicillium and other fungi |

0.87 |

||

|

Algae |

blue green algae |

10-40 |

Algae |

Paramecia |

7.30 |

|

Chlorella |

0.93 |

Chlorella |

1.22 |

||

|

nematode eggs |

3.40 |

protozoa |

4-6.70 |

||

|

Fish Disease |

Fung1 disease |

1.60 |

Fish Disease |

Infected Pancreatic Necrosis |

4.0 |

|

Vitiligo |

2.67 |

viral hemorrhagic disease |

1.6 |

The sterilization efficiency of ultraviolet technology on common bacteria and viruses (ultraviolet radiation intensity 30mW/cm2)

|

Dose Name |

90% |

99% |

99.9% |

99.999% |

99.9999% |

|

(uw.s/cm²) |

(uw.s/cm²) |

(uw.s/cm²) |

(uw.s/cm²) |

(uw.s/cm²) |

|

|

Escherichia coli |

3000 |

4800 |

6600 |

10500 |

15000 |

|

Salmonella |

2700 |

4100 |

5500 |

7100 |

8500 |

|

Rotavirus |

9100 |

19000 |

26000 |

36000 |

48000 |

Dosage required for bacteria and microorganisms ultraviolet disinfection (99.9% sterilization effect)

|

Dose Name |

99.9% |

Dose Name |

99.9% |

|

(uw.s/cm²) |

(uw.s/cm²) |

||

|

BACTERIA |

MOLD SPORES |

||

|

Bacillus anthracis |

8700 |

Aspergillus flavus |

99000 |

|

Bacillus |

2500 |

mucormyces multiclade |

35200 |

|

Bacillus subtilis |

11000 |

VIRUSES |

|

|

Bacillus subtilis |

22000 |

coliphage |

6600 |

|

Clostridium tetani |

22000 |

Phage |

6600 |

|

diphtheria |

6500 |

Enteritis virus |

8000 |

|

Escherichia coli |

6600 |

cold virus |

6600 |

|

spheroid protein micrococcus |

15400 |

Poliovirus |

6000 |

|

Mycobacterium tuberculosis |

10000 |

Cryptospordium |

19000 |

|

Salmonella enteritidis |

7600 |

Staphylococcus faecalis |

10000 |

|

Shigella |

4200 |

Streptococcus |

3800 |

|

Staphylococcus aureus |

6600 |

Vibrio cholerae |

6500 |

Optimal conditions for use of UV sterilizers

Iron content: not more than 0.3ppm (0.3mg/L) Suspended solids: not more than 10 ppm (10mg/L) Water hardness: not more than 120 mg/L

Water temperature: 5℃~60℃

Hydrogen sulfide: not more than 0.05 ppm (0.05 mg/L) Manganese content: not more than 0.5 ppm (0.5 mg/L) Chroma: not more than 15 degrees

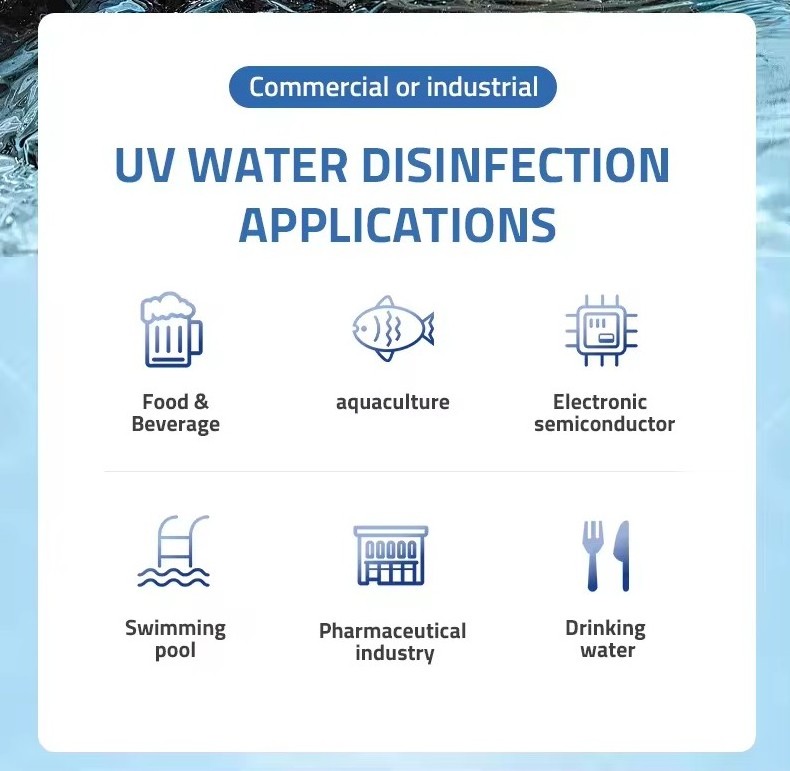

Application range of ultraviolet sterilizer

Water disinfection for food, beverage, pharmaceutical, fruit deep processing, etc.

Ultrapure water in electronics industry, field water supply system in military camps

Hospital, laboratory water, high-content pathogenic body wastewater disinfection

Drinking water disinfection in residential quarters, office buildings, hotels, restaurants, waterworks, etc.

Aquaculture, mariculture, freshwater nursery, aquatic product processing purification and disinfection, etc.

Disinfection of urban sewage, reclaimed water and landscape water

Water disinfection for swimming pools and water parks

Disinfection of cooling water for thermal power, industrial production, and central air-conditioning system

Sterilization of biological, chemical pharmaceutical, and cosmetic production water

Disinfection and purification required for high-end environments such as agricultural breeding, agricultural greenhouses, and agricultural irrigation

|

Model |

Treated Water Volume T/H |

Inlet diameter mm |

Power W |

Work Pressure MPa |

|

UVC-20(1050W) |

50-55 |

DN150 |

1050 |

0.8 |

|

UVC-20(1200W) |

55-60 |

DN150 |

1200 |

0.8 |

|

UVC-20(1350W) |

60-65 |

DN150 |

1350 |

0.8 |

|

UVC-20(1500W) |

65-75 |

DN150 |

1500 |

1.0 |

|

UVC-20(1650W) |

75-85 |

DN150 |

1650 |

1.0 |

|

UVC-20(1800W) |

85-90 |

DN150 |

1800 |

1.0 |

|

UVC-20(2100W) |

90-100 |

DN150 |

2100 |

1.0 |

|

UVC-20(2400W) |

100-120 |

DN150 |

2400 |

1.0 |

|

UVC-20(2700W) |

120-135 |

DN150 |

2700 |

1.0 |

|

UVC-20(3000W) |

135-150 |

DN200 |

3000 |

1.0 |

|

UVC-20(3600W) |

150-180 |

DN200 |

3600 |

1.0 |

|

UVC-20(4500W) |

180-220 |

DN200 |

4500 |

1.0 |

|

UVC-20(5400W) |

220-280 |

DN200 |

5400 |

1.0 |

|

UVC-20(6000W) |

280-300 |

DN250 |

6000 |

1.0 |

Note: The amount of water treated by the above products is for reference only. Different industries and different water quality selections are different, and the selection parameters of the actual working conditions shall prevail.

|

Model |

Treated Water Volume T/H |

Inlet diameter mm |

Power W |

Work Pressure MPa |

|

UVC-20(300W) |

12-15 |

DN65 |

300 |

0.6 |

|

UVC-20(360W) |

15-18 |

DN80 |

360 |

0.6 |

|

UVC-20(400W) |

18-20 |

DN80 |

400 |

0.6 |

|

UVC-20(480W) |

20-23 |

DN80 |

480 |

0.6 |

|

UVC-20(500W) |

23-25 |

DN100 |

500 |

0.6 |

|

UVC-20(600W) |

25-30 |

DN100 |

600 |

0.6 |

|

UVC-20(720W) |

30-35 |

DN100 |

720 |

0.6 |

|

UVC-20(840W) |

35-40 |

DN100 |

840 |

0.8 |

|

UVC-20(960W) |

40-50 |

DN150 |

960 |

0.8 |

Note: The amount of water treated by the above products is for reference only. Different industries and different water quality selections are different, and the selection parameters of the actual working conditions shall prevail.

Product introduction

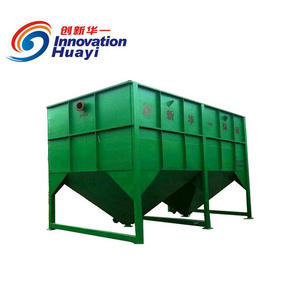

Medium-pressure ultraviolet disinfection equipment is based on The Company's many years of experience in ultraviolet disinfection and combined with the experience in many large and medium-sized municipal water disinfection treatments and swimming pool water disinfection treatments. It is jointly developed by professors from various disciplines, design engineers, on-site operators, etc. Research and development of high-tech products.

Product advantages

Wide range of sterilization and disinfection

The medium-pressure ultraviolet lamp output wavelength range of the medium-pressure ultraviolet sterilization system is wide, between 230nm and 370nm, which can kill bacteria and viruses, and can inactivate chlorine-resistant microbial tissues, such as Legionella pneumophila , Escherichia coli, Pseudomonas, Cryptosporidium, amoeba and bacteria, etc.

Strong sterilization effect

While damaging the DNA structure of microorganisms, it also decomposes the microorganisms into small fragments. It is precisely because of this medium-pressure ultraviolet sterilization characteristic that it can avoid the occurrence of photorevival and dark repair of DNA in microorganisms, so it can kill microorganisms. There is no sterilization effect, no resurrection reaction, and no rebound phenomenon of bacterial flora.

No secondary pollution

During the disinfection process, no toxic and harmful by-products will be produced, the composition and properties of the disinfected water will not be changed, and no secondary pollution will be caused to the water body and the surrounding environment.

Decompose residual chlorine in water and degrade combined chlorine

When used for water sterilization and disinfection, medium-pressure ultraviolet sterilizers can reduce the chlorine content in the water, reduce disinfection by-products, and make the water environment healthier. Medium-pressure ultraviolet rays have the ability to degrade combined chlorine, including monochloramine, dichloramine, trichloramine, etc. This reduces the production of carcinogen trihalomethanes and reduces the impact of combined chlorine on the human body.

Low cost of use

Due to the improvement of ultraviolet disinfection technology, medium-pressure ultraviolet disinfection technology can not only ensure disinfection efficiency, but also simple disinfection operation and maintenance, low operating costs, and can reach 4 cents per ton of water at the thousand-ton treatment capacity level. Easy to install and operate

The medium-pressure ultraviolet disinfection system is modular in design, easy to install, suitable for complex installation site conditions, and does not damage on-site equipment, pipelines and building structures. Closed system design for direct installation into pipes, optional horizontal and vertical installation.

The medium-pressure ultraviolet disinfection equipment, which occupies a small area and is noise-free, can process 10,000 tons of purified water per day, requires only 6 square meters of operating space.

Continuous large volume water disinfection

At present, ultraviolet disinfection technology has reached a daily processing capacity of 1.5 million tons of water in practical applications, and it can be larger if actual needs are required. This is something that chlorine disinfection and ozone disinfection cannot achieve. Wide range of applications

Medium-pressure ultraviolet disinfection equipment can be used in the catering industry, swimming pools, wastewater, wastewater reuse and offshore oil and gas to meet the disinfection requirements of various industries.

Application industry

It is suitable for disinfection of effluent from large and medium-sized drinking water treatment plants; purification and disinfection of swimming pool water; decomposition of residual chlorine and its products in water; degradation of chemical pollutants in drinking water;

And the degradation of some refractory organic matter in industrial wastewater.

Features of medium pressure ultraviolet poison destroyer

Medium pressure UV lamp

Using medium-voltage high-quality lightsources brand ultraviolet lamps imported from the United States, they are high-power and can reduce the number of lamp configurations and can handle large-flow water bodies.

Special matching ballast

It has dimming control function, and has protection functions such as output short circuit, output open circuit, output overvoltage, input overvoltage, input undervoltage, and overtemperature; it has the monitoring function of lamp current and voltage; it has PLCIO hard wire, CAN bus, RS485/ 422 communication function.

temperature probe

Real-time detection of water temperature to ensure that the equipment operates within the working temperature range of 0 to 45 degrees. UV intensity probe

The intensity monitor used in medium-pressure UV sterilizers responds to specific UV wavelengths that have a sterilizing effect. It can be connected to computers and PLCs, saving power consumption for system operation.

quartz sleeve

In order to protect the UV lamps reliably, there is a quartz sleeve outside each UV lamp. Therefore, the quality of the quartz sleeve also determines the sterilization effect of the medium-pressure ultraviolet sterilizer. The ultraviolet penetration rate of quartz sleeves with high purple transmittance reaches 90% and above.

daily cleaning

The medium-pressure UV sterilizer is equipped with an automatic cleaning system, which can automatically clean the quartz sleeve at regular intervals based on the readings of the UV intensity detector. During the cleaning process, the system operates normally without water outage or manual intervention, which greatly reduces the workload of on-site personnel.

|

Model |

Power KW |

Lamp Power KW |

Lamp Quantity PCS |

Flow Rate T/H |

Port Size |

Voltage V |

|

UUVC-1/1.0KW |

1.0 |

1.0 |

1 |

30-40 |

DN100 |

110/220/380/440 |

|

UUVC-1/2.0KW |

2.0 |

2.0 |

1 |

60-80 |

DN125 |

110/220/380/440 |

|

UUVC-1/3.0KW |

3.0 |

3.0 |

1 |

100-125 |

DN150 |

110/220/380/440 |

|

UUVC-2/2.0KW |

4.0 |

2.0 |

2 |

130-150 |

DN200 |

110/220/380/440 |

|

UUVC-2/3.0KW |

6.0 |

3.0 |

2 |

200-250 |

DN250 |

110/220/380/440 |

|

UUVC-3/3.0KW |

9.0 |

3.0 |

3 |

250-300 |

DN250 |

110/220/380/440 |

Note: The amount of water treated by the above products is for reference only. Different industries and different water quality selections are different, and the selection parameters of the actual working conditions shall prevail.

Features

Efficient fully automatic mechanical cleaning device (pneumatic cleaning type, water cleaning type for users to choose) so that the normal work of the disinfection system will not be affected during cleaning, and no human operation is required

Patented product with intellectual property rights, water pressure-powered cleaning system, convenient, fast, environmentally friendly, energy-saving, and no noise pollution

External distribution box can be placed in a separate space and operated separately from the cavity

The whole machine is made of SUS304/316L (optional) stainless steel, polished inside and outside, with high cleanliness and disinfection effect Good fruit, environmental sanitation and other characteristics

Equipped with an ultraviolet intensity monitoring system, which is convenient for monitoring the fouling of the quartz tube and the change in the intensity of the ultraviolet lamp (optional)

Equipped with working indicator light, cumulative working hours, alarm system (optional)

Equipped with high light transmittance, imported raw material quartz sleeve and high stability medium/low pressure germicidal lamp, the service life is as high as 12000 hours

Equipped with a special ballast for ultraviolet rays, it works stably to ensure the life and efficiency of ultraviolet germicidal lamps

|

Model |

Treated Water Volume T/H |

Inlet diameter mm |

Power W |

Work Pressure MPa |

|

A-UUVC-480 |

20-25 |

80 |

480 |

0.8 |

|

A-UUVC-600 |

25-30 |

80 |

600 |

0.8 |

|

A-UUVC-720 |

35-40 |

100 |

720 |

0.8 |

|

A-UUVC-840 |

40-50 |

100 |

840 |

0.8 |

|

A-UUVC-960 |

50-55 |

150 |

960 |

0.8 |

|

A-UUVC-1050 |

55-60 |

150 |

1050 |

0.8 |

|

A-UUVC-1200 |

60-70 |

150 |

1200 |

1.0 |

|

A-UUVC-1350 |

70-80 |

150 |

1350 |

1.0 |

|

A-UUVC-1500 |

80-90 |

200 |

1500 |

1.0 |

|

A-UUVC-1800 |

90-100 |

200 |

1800 |

1.0 |

|

A-UUVC-2100 |

100-110 |

250 |

2100 |

1.0 |

Note: The amount of water treated by the above products is for reference only. Different industries and different water quality selections are different, and the selection parameters of the actual working conditions shall prevail.

Product Show