- Product Details

- {{item.text}}

Quick Details

-

Welding Area:

-

Depend

-

Use:

-

Plastic Welders, Mask Ear Strap Welding

-

Weight (KG):

-

20 KG

-

Power (kW):

-

0.5

-

Application:

-

Auto,Toy,Non-woven,Medical Industry

-

Product name:

-

Metal Automotive Terminal Wiring Harness Ultrasonic Welding Cable Line

-

Keyword:

-

Ultrasonic Spot Welder

-

Item name:

-

Ultrasonic Welding Equipment

-

Function:

-

PE PP PVC Plastic Welder

-

Type:

-

Semi-automatic

-

Feature:

-

High Working Efficiency

-

Keywords2:

-

Ultrasonic Plastic Welding Machine

-

Machine Type:

-

Plastic Bag Making Machine

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PULISONIC

-

Frequency:

-

28KHz

-

Welding Area:

-

Depend

-

Use:

-

Plastic Welders, Mask Ear Strap Welding

-

Weight (KG):

-

20 KG

-

Power (kW):

-

0.5

-

Application:

-

Auto,Toy,Non-woven,Medical Industry

-

Product name:

-

Metal Automotive Terminal Wiring Harness Ultrasonic Welding Cable Line

-

Keyword:

-

Ultrasonic Spot Welder

-

Item name:

-

Ultrasonic Welding Equipment

-

Function:

-

PE PP PVC Plastic Welder

-

Type:

-

Semi-automatic

-

Feature:

-

High Working Efficiency

-

Keywords2:

-

Ultrasonic Plastic Welding Machine

-

Machine Type:

-

Plastic Bag Making Machine

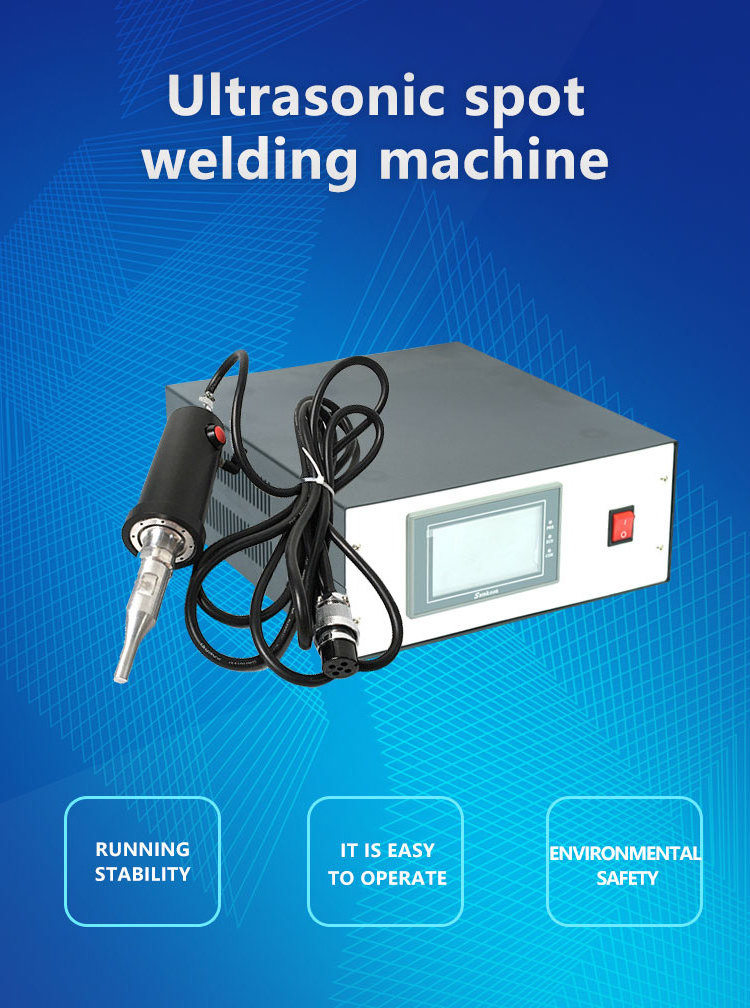

Handheld 28khz High Frequency Ultrasonic Welding Machine Small Ultrasonic Hand Welder Portable Spot Welder For Plastic Bag

Ultrasonic spot welder can be used not only to weld hard thermoplastics, but also to process fabrics and films. The main components of an ultrasonic welding system include ultrasonic generator, transducer/amplitude modulator/welding head triple group, mold and frame.Ultrasonic spot welding machine can also be used for welding, riveting, spot welding of thermoplastic products, as well as the inlay and edge pressing process between metal and plastic parts. It eliminates the backward process of pasting with chemical organic melting point agents and has low energy consumption. , High efficiency, no deformation, no pollution, firm welding, convenient operation, etc. The product adopts advanced circuit, program control, pneumatic transmission, automatic overcurrent protection, and safe operation protection circuit. The circuit adopts a circuit board plug-in structure, which is convenient for maintenance and replacement. A new 15KHz ultrasonic plastic welding machine with an electronic delay welding device is also designed. Welding softer PE and PP materials, as well as plastic weldments with extra large diameters and long lengths, have their unique advantages, which can meet the needs of various products and contribute to the improvement of production efficiency and product quality for users.

Ultrasonic spot welding machine,suitable for a wide range of applications, such as: car consoles, car door panels, car interiors, car interior sound insulation cotton, car interior sound insulation panels, car bumpers, car glove boxes, non-woven fabrics, pp plastic Plates, PP plastic film, PET plastic film, advertising cloth, chicken farm conveyor belts, various conveyor belts, sound-proof blankets, and clothing applications such as: mask belts, clothing elastic bands, underwear belts, medical equipment products, etc.

| Type | Power(W) | Frequency (KHz) |

| PLS-DHJ-300 | 300W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-500 | 500W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-800 | 800W | 15KHz/20khz/28khz/40khz |

| PLS-DHJ-900 | 900W | 15KHz/20khz |

| PLS-DHJ-1000 | 1000W | 15KHz/20khz |