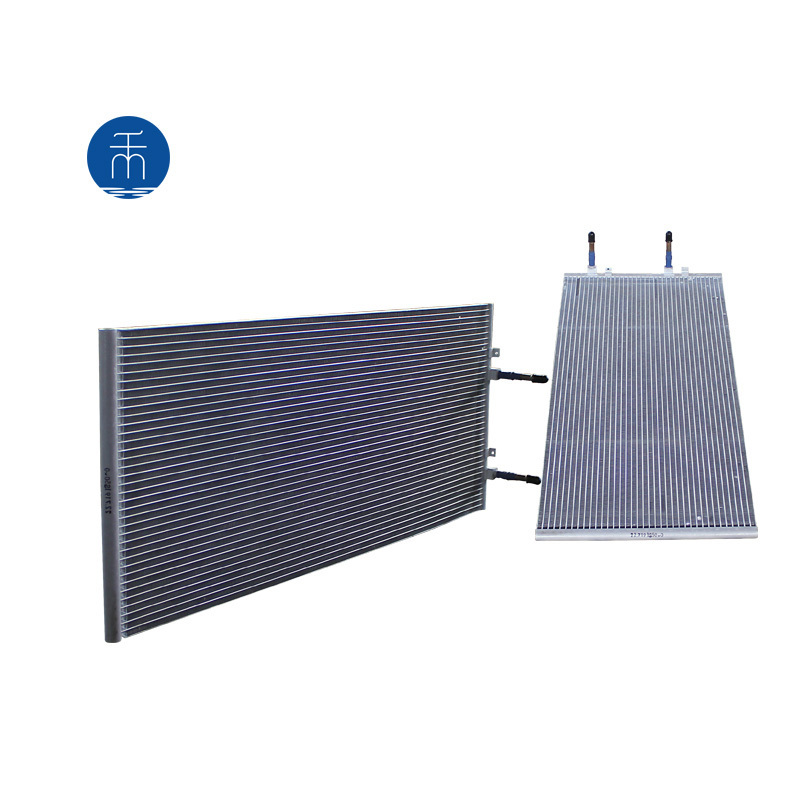

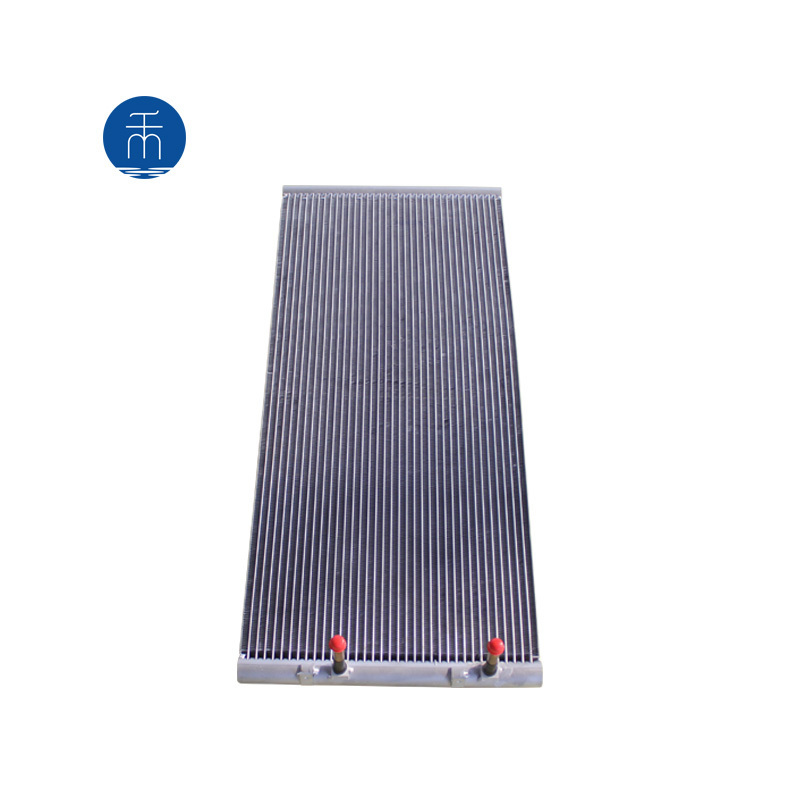

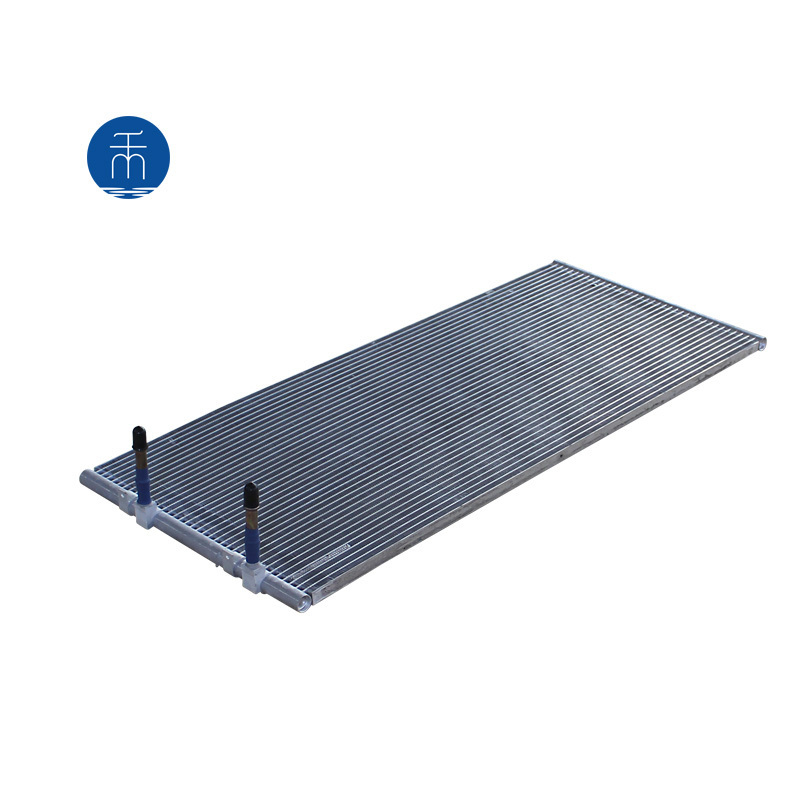

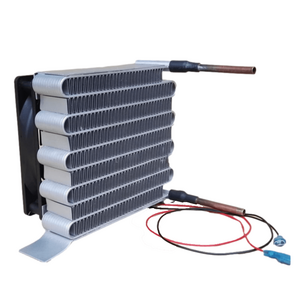

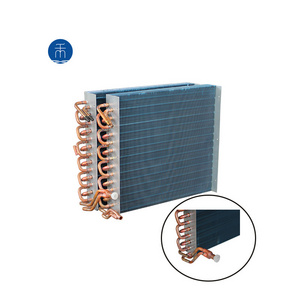

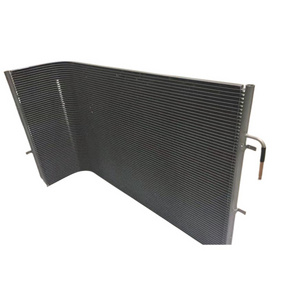

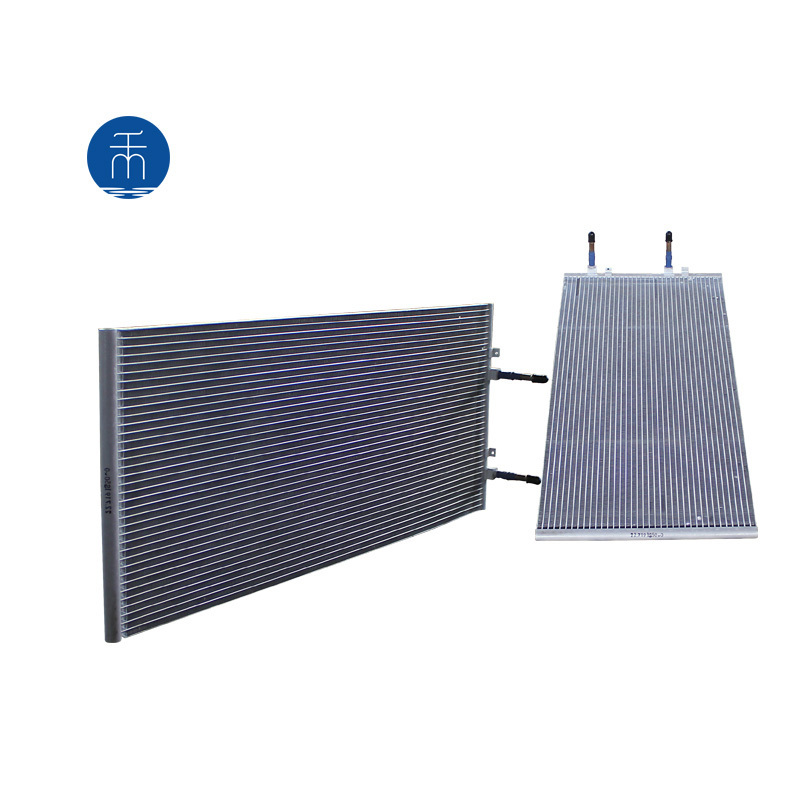

OEM Custom Aluminum Micro Channel Air Conditioner Microchannel Condenser Coil for Evaporator

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dayuan

-

Liquid Flow Rate:

-

2 cub m/s

-

Maximum Working Pressure:

-

25bar

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

800*460*650mm

-

Working Temperature Range:

-

-50C-150C

-

FINS:

-

aluminium

-

tube:

-

ss304

-

Frame:

-

SS304

-

Product Name:

-

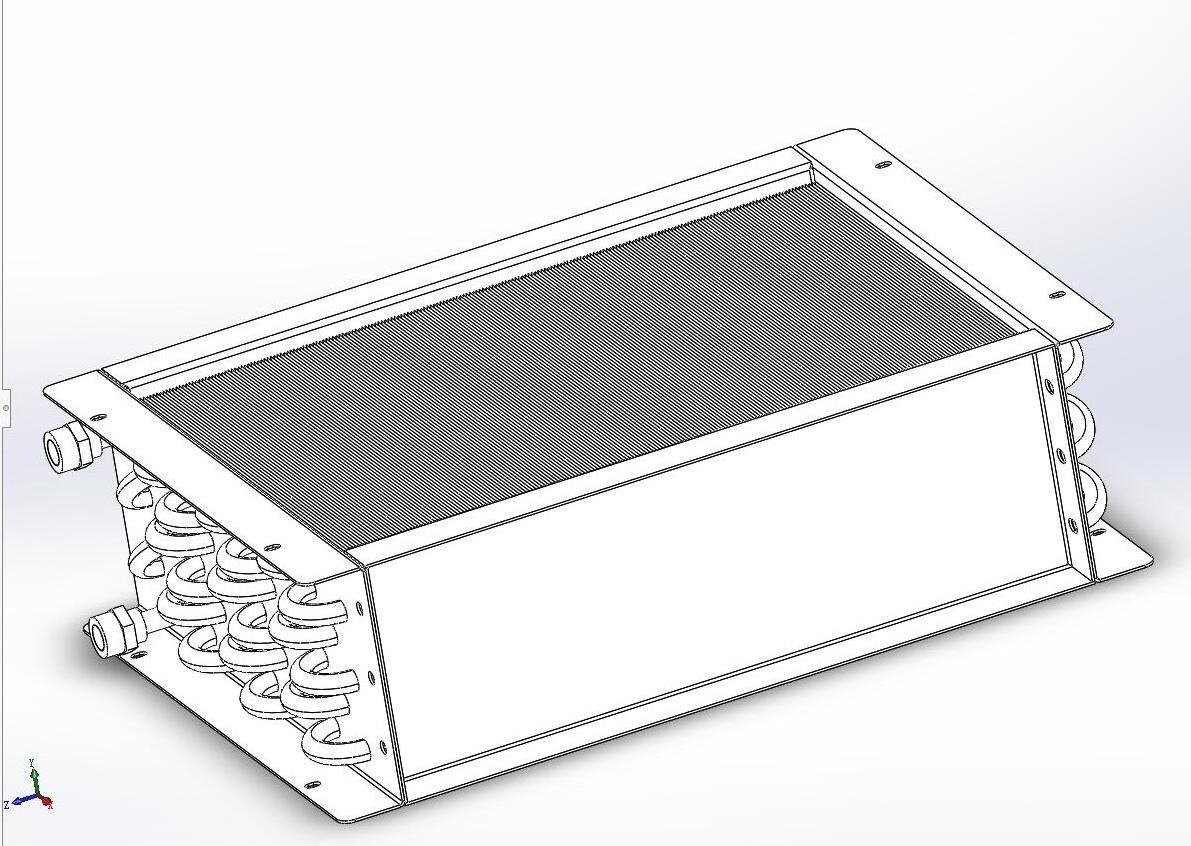

Finned Tube Heat Exchanger

-

Feature:

-

mini heat exchanger

-

Application:

-

Heat Transfer

-

Type:

-

U shape finned heat exchanger

Quick Details

-

Structure:

-

Finned Tube Heat Exchanger

-

Voltage:

-

-

-

Core Components:

-

TUBE

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dayuan

-

Liquid Flow Rate:

-

2 cub m/s

-

Maximum Working Pressure:

-

25bar

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

800*460*650mm

-

Working Temperature Range:

-

-50C-150C

-

FINS:

-

aluminium

-

tube:

-

ss304

-

Frame:

-

SS304

-

Product Name:

-

Finned Tube Heat Exchanger

-

Feature:

-

mini heat exchanger

-

Application:

-

Heat Transfer

-

Type:

-

U shape finned heat exchanger

Products Description

Dayuan Customized

Micro-Channel

Heat Exchangers

The flow and heat transfer phenomena in microchannels depend on their excellent Heat exchange efficiency, high pressure

resistance, corrosion resistance, compact structure and cost saving This has many advantages [1], and is increasingly used in

aerospace, electrical, Information technology, air conditioning, micro-electromechanical systems and other fields. At present, for

The definition of microchannel heat exchanger is that the hydraulic diameter is less than 1 mm. The heat exchanger is called a

microchannel heat exchanger. Classify according to that application approach, the microchannel Heat exchangers can be divided into

two categories: chip cooling and industrial heat exchange. At present, The research on microchannel heat exchanger is mainly

focused on the internal flow of microchannel. Fluid flow, heat transfer mechanism, internal structure and optimization of

microchannel heat exchanger Frosting problem and the like. In this paper, the structure, mechanism, The research status of theory

and application are reviewed.

resistance, corrosion resistance, compact structure and cost saving This has many advantages [1], and is increasingly used in

aerospace, electrical, Information technology, air conditioning, micro-electromechanical systems and other fields. At present, for

The definition of microchannel heat exchanger is that the hydraulic diameter is less than 1 mm. The heat exchanger is called a

microchannel heat exchanger. Classify according to that application approach, the microchannel Heat exchangers can be divided into

two categories: chip cooling and industrial heat exchange. At present, The research on microchannel heat exchanger is mainly

focused on the internal flow of microchannel. Fluid flow, heat transfer mechanism, internal structure and optimization of

microchannel heat exchanger Frosting problem and the like. In this paper, the structure, mechanism, The research status of theory

and application are reviewed.

We support the selection of different model sizes or the customization of drawings.

Customized boundary dimension

FREE design. 3D drawing comfirm.

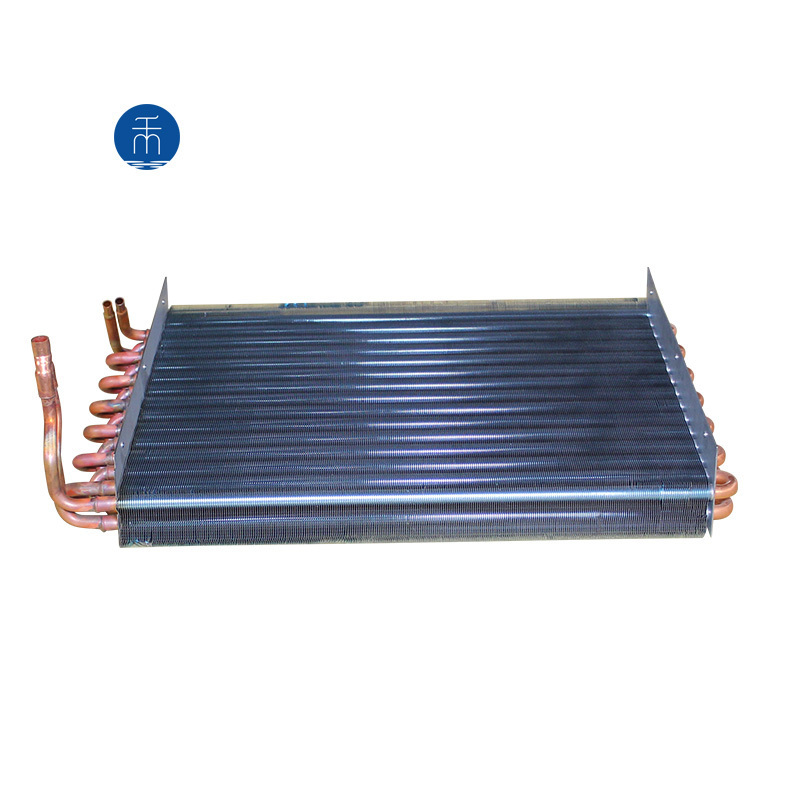

All Kinds Heat Exchanger

Finned tube heat exchanger is widely used in power, chemical, petrochemical, air conditioning engineering and refrigeration engineering such as surface air cooler, air heater, fan coil used in air conditioning engineering. Refrigeration engineering used in the chiller evaporator, frost-free refrigerator evaporator, etc., it is not only applicable to the flow of single-phase fluids, but also to the phase change of heat is also of great value.

Cooling tower is a device that uses water as a recirculating coolant and absorbs heat from a system and discharges it into the atmosphere to lower the temperature of the water. The role of the cooling tower is to carry waste heat cooling water inside the tower body and the air for heat exchange, so that the waste heat transfer to the air and dissipated into the atmosphere.

Cooling tower is mainly used in air conditioning cooling system, freezing series, injection molding, industrial water cooling and other fields.

Shell and tube heat exchanger is a spiral tube bundle design, which can maximize the turbulence effect and increase the heat exchange efficiency. The asymmetric design of the internal shell and tube layer makes it widely used in the field of vapor-water heat exchange. Since the shell and tube heat exchanger is mostly stainless steel 316L as the main body of the heat exchanger, it will become a must for the beverage, food, and pharmaceutical industries.

Absorbed heat exchanger is a metal tube bent into a variety of shapes suitable for the container, and immersed in the liquid inside the container. Its advantages are simple structure, can withstand high pressure, can be made of corrosion-resistant materials; its disadvantage is that the degree of turbulence of the liquid in the container is low, outside the tube to the heat coefficient is small. In order to improve the heat transfer coefficient, the vessel can be installed inside the agitator.

Double-pipe heat exchanger is a concentric casing made of two different sizes of standard tubes connected together, the outside is called the shell course, the inside is called the pipe course. Two different media can be in the shell and tube flow in the reverse direction (or the same direction) to achieve the effect of heat transfer. It is widely used in petrochemical, refrigeration and other industrial sectors.

One-Stop Total Solution

Rich In Experience

We have very rich industry experience and are also your trusted supplier .

The company has advanced production equipment and skilled front-line employees .

We have obtained SO900L CEcertificates

Customer Service

Dedicated to strict quality control and thoughtful customer service , our experienced staff members are aways available to discuss your requirements and ensure full customer satisfaction .

OEM/ODM

We can accept OEM or ODM order . Whether selecting a current product from our catalog or seeking engineering assistance for your application , you can talk to our customer service center about your sourcing requirements.

|

Laser Cutting Machine

|

Pipe Rolling Machine

|

Pipe Rolling Machine

|

Leveling Machine

|

|

Bending Machine

|

Rolling Machine

|

Sand blasting machine

|

Lathe Machine

|

|

Flame Cutting Machine

|

CNC Milling Machine

|

Drilling Machine

|

Drilling Machine

|

|

Pipe Bending Machine

|

Punching Machine

|

Sawing Cutting Machine

|

Spring Machine

|

Laser Cutting Machine

Leveling Machine

Bending Machine

CNC Milling Machine

Flame Cutting Machine

High-speed Punching Machine

If you are interested in any of our products,

please do not hesitate to contact us for further information.

Hot Searches