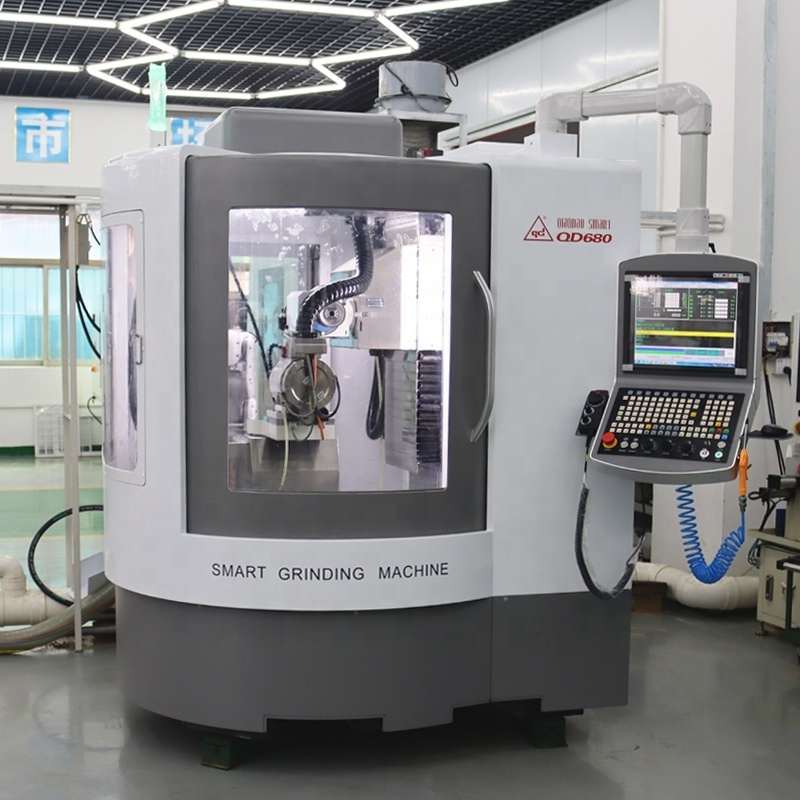

QD680 is a six-axis CNC tool grinding machine. The machine tool, through the corresponding tool grinding software, can automatically complete the grinding of bar tools with outer diameter of 0.5~12 mm and length of 0~150 mm. By clamping different

grinding wheel flange components, it can also complete the axial slotting, front angle and rear angle sharpening of special tools at one time, greatly improving the work efficiency, eliminating the positioning error caused by multiple times of clamping, and improving the grinding precision. It especially applies to tool manufacturing and regrinding by tool manufacturers and production enterprises.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

qiandao

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1600X1550X2100 mm

-

Weight (KG):

-

3500

-

Power (kW):

-

18

-

Application:

-

Tool Manufacturing And Grinding

-

Max. Grinding Diameter:

-

10mm

-

Control system:

-

SYNTEC system

-

Model:

-

QD680

-

Motor:

-

YASKAWA servo motor

-

Rolling linear guide:

-

HIWIN rolling linear guide

-

Gear:

-

NSK precision gear

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Wheel Size(mm):

-

50~200mm

-

Year:

-

2022

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

qiandao

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1600X1550X2100 mm

-

Weight (KG):

-

3500

-

Power (kW):

-

18

-

Application:

-

Tool Manufacturing And Grinding

-

Max. Grinding Diameter:

-

10mm

-

Control system:

-

SYNTEC system

-

Model:

-

QD680

-

Motor:

-

YASKAWA servo motor

-

Rolling linear guide:

-

HIWIN rolling linear guide

-

Gear:

-

NSK precision gear

-

After-sales Service Provided:

-

Field installation, commissioning and training

Product Description

Purpose and scope of application of the machine tool

Title goes here.

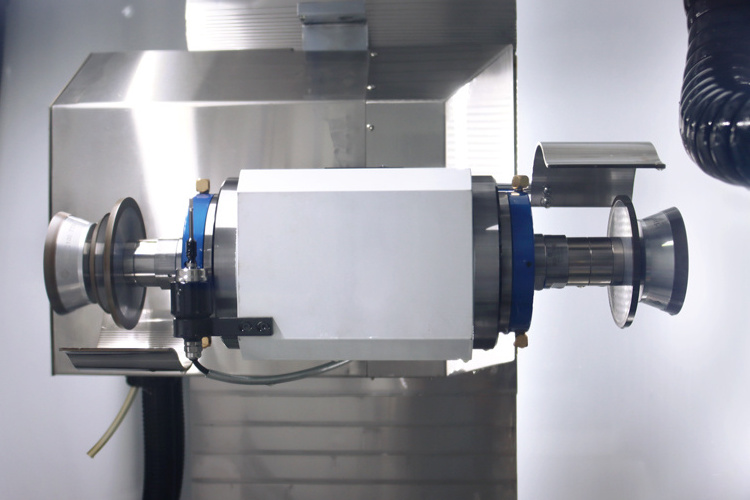

Machine body(base,X carrier,Y carrier,Z carrier and Z column)are all made of natural granite with excellent thermal stability and vibration absorption,3-coordibate granite base adopt high precision grinding processing technology. Linear axis X,Y,Z adopt ball screw linear guide drive.Rotation spindle A-axis adopts powerful direct-drive conversion, B-axis and C-axis adopts turbo conversion.

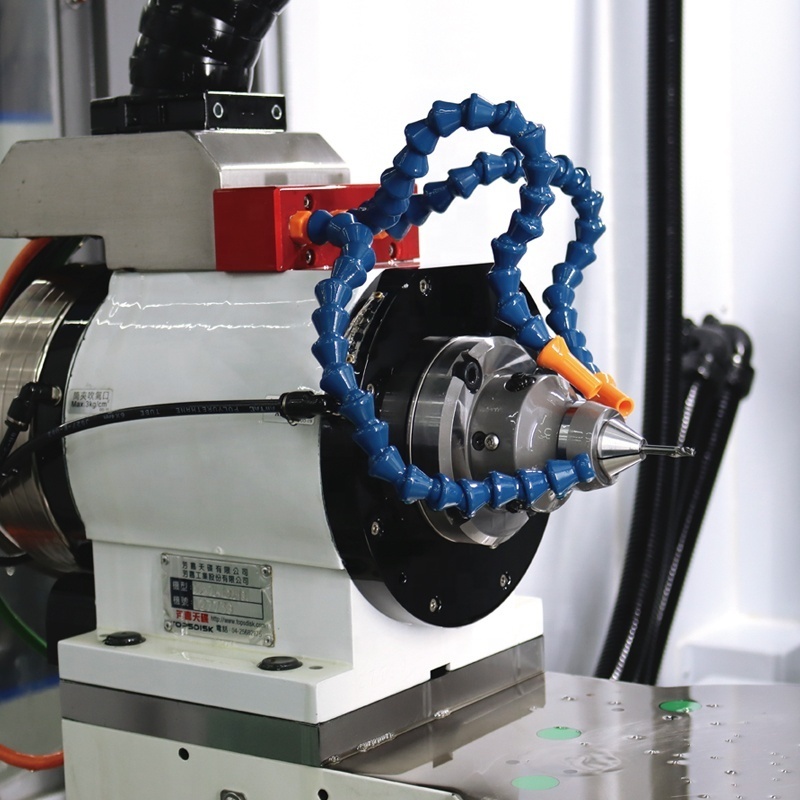

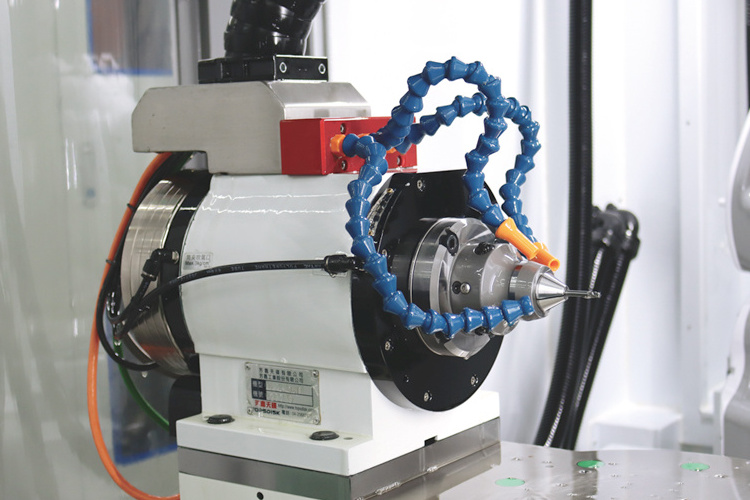

Grinding Head.

The machine tool adopts high-precision, direct-drive variable-frequency motorized spindle.

The machine tool adopts high-precision, direct-drive variable-frequency motorized spindle.

The spindle has two sets of grindingwheel flanges. Each set of flanges can be equipped with 2 to 4 grinding wheels at the same time. According to the grinding process, the grinding wheel group can be changed quickly, which can fully satisfy various tools Grinding needs.

Workpiece spindle A axis.

.

The workpiece spindle ( A axis) adopts dd direct drive, equipped with W20 tool holder and collet.

The workpiece is automatically clamped.

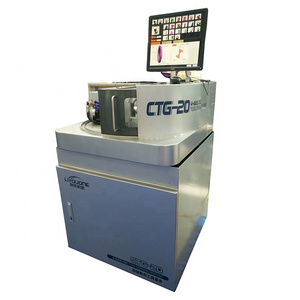

Operation panel.

.

Function keys integrated into the operator panel for quick configuration of operation. ✮The display has touch screen function to assist the operator.

The console can be adjusted flexibly.

Durable design for a variety of industrial environments.

Handheld Remote Operator .

.

It is easier for the operator to set up the grinder without going to the screen or leaning over. ✮The remote manipulator has a feed rate control, and the feed rate can be easily changed during commissioning.

It has the function of "hand-held operation" and conforms to CE certification.

Optional.

The machine is equipped Nachi robotic arm. The automatic loading and unloading robot system which can realize full-automatic production for 24 hours.

Machinable tool display

.

Specification

|

MODEL

|

QD680

|

|

CNC system

|

SYNTEC 210MA-5E

|

|

Max diameter of workpiece (Bar)

|

10mm

|

|

Max grinding length

|

150mm

|

|

Max groove depth

|

10mm

|

|

Max weight of workpiece

|

10Kg

|

|

Max motor power of grinding head(Direct drive motorized spindle )

|

11KW

|

|

The size of the grinding wheels(CBN and diamond)

|

Φ50~Φ200mm

|

|

Motorized spindle revolving speed( frequency control)

|

1000-6000rpm

|

|

Travel Y-axis

|

320(-100~220)mm

|

|

Travel of the operating platform(X/Y/Z)

|

X:285 / Y:300 / Z:320

|

|

Linear axis rapid traverse speed

|

15m/min

|

|

Workpiece spindle revolving speed (A-axis)

|

200rpm

|

|

A-axis rotation angle

|

∞

|

|

Pneumatic clamping workpiece range

|

3~16mm

|

|

Max rotation speed (C-axis)

|

75rpm

|

|

C-axis rotation range

|

175°(-15°~+160°)

|

|

Workpiece spindle center height

|

140mm

|

|

Workpiece spindle runout

|

≤0.005mm

|

|

Grinding head spindle runout

|

≤0.005mm

|

|

Cylinder clamping force adjustment range

|

800-1000kg

|

|

Linear resolution

|

0.00lmm

|

|

Rotating axis resolution

|

0.00l°

|

|

Cooling pump power

|

3P

|

|

Source

|

AC 380V 50HZ (three-phase)

|

|

Total machine power

|

18KW

|

|

Machine size

|

1600×1550×2100mm

|

|

Machine weight( approximately)

|

3.5T

|

|

Machine weight( approximately)

|

3.5T

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches