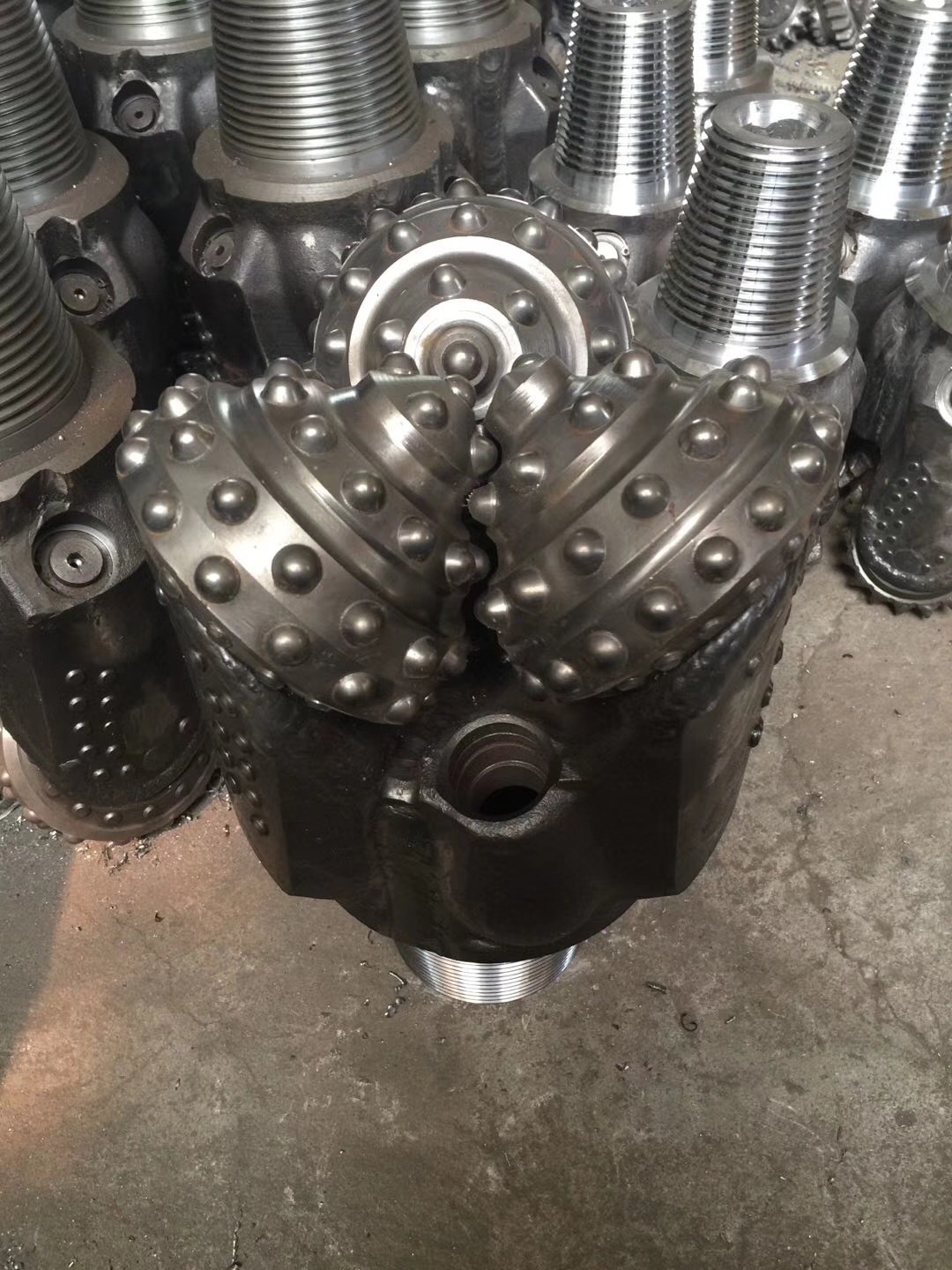

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kingdream,drs,ect.

-

Name:

-

tricone drill head

-

Market:

-

USA, Middle East, South Africa,etc

-

Teeth:

-

insert button

-

Beering type:

-

metal sealed bearing type

-

IADC code:

-

112-837

-

Size:

-

2 5/8''(95.3mm)-26''(660.4mm)

-

Formation:

-

soft to hard formation

-

Conditon:

-

brand new

Quick Details

-

Weight (KG):

-

37

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Kingdream,drs,ect.

-

Name:

-

tricone drill head

-

Market:

-

USA, Middle East, South Africa,etc

-

Teeth:

-

insert button

-

Beering type:

-

metal sealed bearing type

-

IADC code:

-

112-837

-

Size:

-

2 5/8''(95.3mm)-26''(660.4mm)

-

Formation:

-

soft to hard formation

-

Conditon:

-

brand new

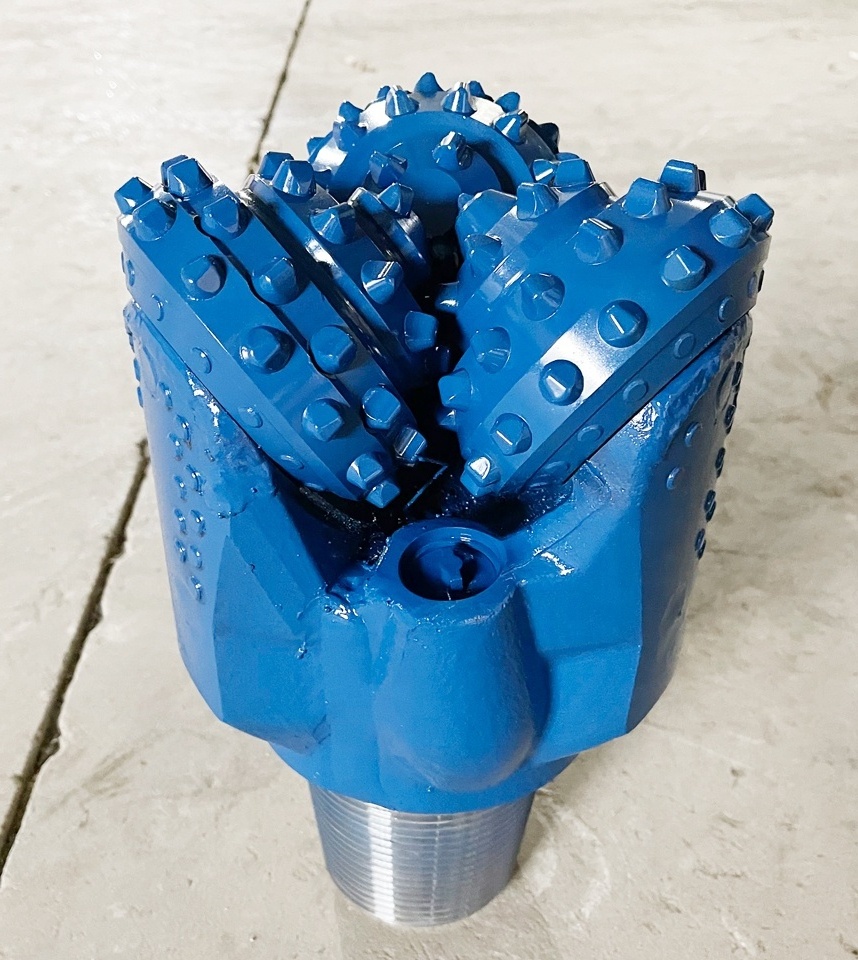

Product Overview

|

Basical Specification

|

|

|

|

Size of tricone bit

|

8 1/2" (215.9mm)

|

|

|

Connection

|

4 1/2"API reg pin

|

|

|

IADC CODE

|

517 537

|

|

|

Bearing type

|

rubber /metal o-ring journal bearing

|

|

|

Operating Parameters

|

|

|

|

Weight On Bit

|

0.35~1.05 KN/mm (bit Dia.)

|

|

|

Rotary speed

|

110~40 r/min / 220~40 r/min

|

|

|

Make up torque

|

16.3~21.7 KN.M

|

|

|

Formation

|

Medium formation with high compressive strength ,and high drillability ,such as mudstone, gypsum, salt,soft limestone,etc.

|

|

The advantage of tricone rock bit

Hard Alloy Welding Perivent bit wear and tear work and protect the bearing

Hard alloy drill palm surface neck protection prevent bit wear in abrasive formation

High strength tungsten carbide teeth ,high temperature hear treatment forged alloy steel

Lubricating system protection of the bearing and seal system of the bit

Sealed Journal bearing

You can find the bit Diameter,thread Pin IADC code Serial number on the bottom

Hard alloy drill palm surface neck protection prevent bit wear in abrasive formation

High strength tungsten carbide teeth ,high temperature hear treatment forged alloy steel

Lubricating system protection of the bearing and seal system of the bit

Sealed Journal bearing

You can find the bit Diameter,thread Pin IADC code Serial number on the bottom

Application

|

IADC

|

WOB(KN/mm Bit Dia.)

|

RPM(r/min)

|

Applicable Formations

|

|||

|

435

515 |

0.20~0.70

|

200~80

|

Soft with very low compressive strength such as shale ,clay, sandstone ,soft limestone ,etc

|

|||

|

535

|

0.35~0.80

|

200~80

|

Medium soft with low compressive strength and harder abrasive stringers ,such as hard shale ,hared gypsolyte, soft limestone,

sandstone and dolomite with stringer ,etc |

|||

|

417

437 |

0.35~0.90

|

140~70

|

Very soft with low compressive strength and high drillability, such as shale, clay, sandstone and conglomerate ,etc.

|

|||

|

517

527 |

0.35~1.05

|

120~50

|

Soft with low compressive strength, such as shale, clay, sandstone, soft limestone, salt bed and hard gypsolyte, etc

|

|||

|

537

547 |

0.35~1.05

|

110~40

|

Medium soft with low compressive strength and harder abrasive stringers, such as hard shale, hard gypsolyte, soft limestone,

sandstone and dolomite with stringers ,etc |

|||

|

617

627 |

0.35~1.05

|

80~40

|

Medium hard with high compressive strength and thick &hard stringers, such as hard shale, limestone, sandstone and dolomite, etc

|

|||

|

637

737 |

0.70~1.20

|

70~40

|

Medium hard with high compressive strength and high abrasiveness ,such as limestone ,dolomite, sandstone and chert ,etc

|

|||

|

Note: The upper limits of WOB and RPM in above table should not be used simultaneously

|

|

|

|

|||

tricone drill bit Application

1) Revolution of drill bit The revolution speed of the drill bit is the rotation speed of the turntable or the down hole power drilling tool. When the drill bit revolves, the cone also rotates around the axis of the drill bit. The linear speed of each row of teeth on the cone rotating around the axis of the drill bit is different, and the linear speed of the outer row of teeth is the largest.

2) Rotation of the drill bit When the drill bit rotates, the counterclockwise rotation of the cone around the axis of the tooth palm is called auto rotation. The rotation speed of the cone is determined by the revolution speed of the drill bit, and is related to the effect of the teeth on the bottom of the well.

3) Longitudinal vibration (axial vibration) impact crushing of the drill bit The change of the position of the wheel center makes the drill bit reciprocate up and down along the axial direction, which is the longitudinal vibration of the drill bit, which is related to the drill bit structure parameters such as tooth height and tooth spacing and lithology. Soft strata have small amplitudes, while hard strata have large amplitudes. The vibration frequency is proportional to the number of teeth and the speed of the cone.

4) Sliding shear breaking action of drill bit Crushing different types of rock requires different slippage of the drill bit, which

is determined by the structural parameters of the drill bit. In soft formations, bit slippage is large, and in hard formations, it

should be as small as possible or not slipped.

3) Longitudinal vibration (axial vibration) impact crushing of the drill bit The change of the position of the wheel center makes the drill bit reciprocate up and down along the axial direction, which is the longitudinal vibration of the drill bit, which is related to the drill bit structure parameters such as tooth height and tooth spacing and lithology. Soft strata have small amplitudes, while hard strata have large amplitudes. The vibration frequency is proportional to the number of teeth and the speed of the cone.

4) Sliding shear breaking action of drill bit Crushing different types of rock requires different slippage of the drill bit, which

is determined by the structural parameters of the drill bit. In soft formations, bit slippage is large, and in hard formations, it

should be as small as possible or not slipped.

Hot Searches