- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Park

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yinrong

-

Model Number:

-

YR-SZG-01

-

Type:

-

Drainage ditch

-

Product name:

-

Resin drainage ditch

-

Keywords:

-

U-shaped drainage ditch

-

Material:

-

Resin

-

Logo:

-

Customized Logo Acceptable (Extra Charges)

-

Size:

-

Customized Size

-

Color:

-

silvery/as your request

-

Shape:

-

Customized

-

Service:

-

Video Guidance

-

MOQ:

-

1

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

3D model design, Others

-

Application:

-

Park

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yinrong

-

Model Number:

-

YR-SZG-01

-

Type:

-

Drainage ditch

-

Product name:

-

Resin drainage ditch

-

Keywords:

-

U-shaped drainage ditch

-

Material:

-

Resin

-

Logo:

-

Customized Logo Acceptable (Extra Charges)

-

Size:

-

Customized Size

-

Color:

-

silvery/as your request

-

Shape:

-

Customized

-

Service:

-

Video Guidance

-

MOQ:

-

1

Products Description

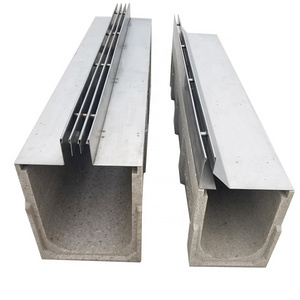

U-Shaped Resin Drainage Ditch

Features:

1. Fast installation, which helps shorten the construction period

2. Smooth U-shaped inner wall prevents garbage accumulation and smooth drainage

3. The construction ditching depth is shallow, the slope finding is simple, easy to construct, and the installation and

construction speed is fast

4. Strong carrying capacity, in line with EN1433 standard

5. It has the characteristics of high-quality anti-aging, anti-freezing, anti-corrosion and environmental stability, zero

penetration, etc.

1. Fast installation, which helps shorten the construction period

2. Smooth U-shaped inner wall prevents garbage accumulation and smooth drainage

3. The construction ditching depth is shallow, the slope finding is simple, easy to construct, and the installation and

construction speed is fast

4. Strong carrying capacity, in line with EN1433 standard

5. It has the characteristics of high-quality anti-aging, anti-freezing, anti-corrosion and environmental stability, zero

penetration, etc.

Product Paramenters

|

Model

|

Total Wide

|

Total Height

|

Total Length

|

Internal Width

|

Internal Height

|

Trench Cover Width

|

|

U100-150-1000

|

140

|

150

|

1000

|

100

|

118

|

115

|

|

U100-200-1000

|

140

|

200

|

1000

|

100

|

168

|

115

|

|

U150-200-1000

|

190

|

200

|

1000

|

150

|

168

|

170

|

|

U150-250-1000

|

190

|

250

|

1000

|

150

|

218

|

170

|

|

U150-300-1000

|

190

|

300

|

1000

|

150

|

168

|

170

|

|

U200-200-1000

|

240

|

200

|

1000

|

200

|

168

|

220

|

|

U200-250-1000

|

240

|

250

|

1000

|

200

|

218

|

220

|

|

U200-300-1000

|

240

|

300

|

1000

|

200

|

268

|

220

|

|

U250-300-1000

|

290

|

300

|

1000

|

250

|

267

|

270

|

|

U300-300-1000

|

340

|

300

|

1000

|

300

|

250

|

320

|

|

U300-350-1000

|

340

|

350

|

1000

|

300

|

300

|

320

|

|

U300-400-1000

|

340

|

400

|

1000

|

300

|

350

|

320

|

|

U400-400-1000

|

460

|

400

|

1000

|

400

|

342

|

441

|

|

U400-500-1000

|

460

|

500

|

1000

|

400

|

442

|

441

|

A U-shaped resin drainage ditch refers to a channel or trench constructed in a U-shape and made from resin-based materials. This type of drainage ditch is commonly used to manage the flow of water, directing it away from specific areas to prevent flooding and water damage. The use of resin-based materials provides advantages such as corrosion resistance, durability, and potentially lower weight compared to traditional materials like concrete or metal.

Details Images

Daily maintenance:

It is recommended to check the usage of the drainage system regularly, at least once a year.

Check content:

1. Check the fixing condition between the drainage ditch cover and the tank. If the screws fixing the cover are loose, use

special tools to tighten.

2. Clean the collection well, clean the dirt blue, and clean the entrance of the municipal drainage system;

3. Clean the drainage ditch. Remove the cover plate and clean up the debris in the trench;

4. Clean the sediment in the drainage ditch;

5. Repair the damaged part of the drainage ditch body;

6. Use special sealant to repair the joints of the drainage ditch body;

7. Restore all parts and fasten them with screws.

It is recommended to check the usage of the drainage system regularly, at least once a year.

Check content:

1. Check the fixing condition between the drainage ditch cover and the tank. If the screws fixing the cover are loose, use

special tools to tighten.

2. Clean the collection well, clean the dirt blue, and clean the entrance of the municipal drainage system;

3. Clean the drainage ditch. Remove the cover plate and clean up the debris in the trench;

4. Clean the sediment in the drainage ditch;

5. Repair the damaged part of the drainage ditch body;

6. Use special sealant to repair the joints of the drainage ditch body;

7. Restore all parts and fasten them with screws.

Application

Hot Searches