- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RT008

-

Power:

-

25KW, 15-20Kw

-

Weight (KG):

-

22000 kg

-

Product name:

-

waste tyre plastic recycling to pyrolysis oil plant

-

Application:

-

Waste Recycling

-

Certification:

-

ISO 9001/CE

-

Material:

-

Q345R boiler steel

-

Capacity:

-

3-15Tons per day

-

Voltage:

-

380v/220v

-

Operating pressure:

-

Ordinary pressure

-

Model of cooling:

-

Water cooling

Quick Details

-

Production Capacity:

-

500L/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

REALTOP

-

Model Number:

-

RT008

-

Power:

-

25KW, 15-20Kw

-

Weight (KG):

-

22000 kg

-

Product name:

-

waste tyre plastic recycling to pyrolysis oil plant

-

Application:

-

Waste Recycling

-

Certification:

-

ISO 9001/CE

-

Material:

-

Q345R boiler steel

-

Capacity:

-

3-15Tons per day

-

Voltage:

-

380v/220v

-

Operating pressure:

-

Ordinary pressure

-

Model of cooling:

-

Water cooling

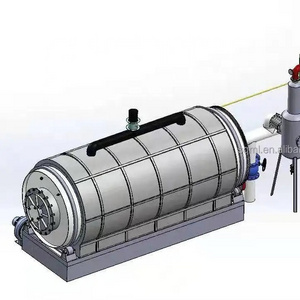

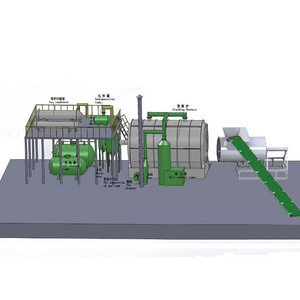

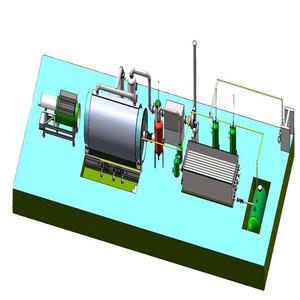

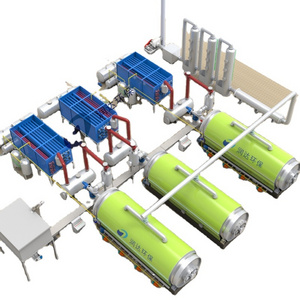

Professional waste tyre plastic recycling to pyrolysis oil plant

Working process of professional waste tyre plastic recycling to pyrolysis oil plant

feed raw material (belt conveyor)-- heat(reactor)-- oil gas comes into being-- impurity

deposits(gas separate)-- heavy oil deposits(depositing tank)-- cooling down(cooling pool)

- get light oil(light oil tank)-- flammable gas reheat reactor-- take out carbon black(

screw conveyor)

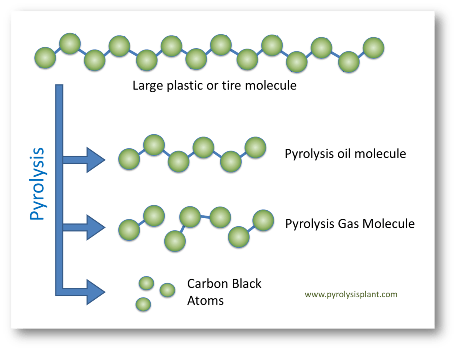

What is pyrolysis?

Pyro = heat. Lysis = break down.

◊ fuel oil from waste tyre are used in below industries

A.power plant factory

B.glass factory

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

◊carbon black from waste tyre are used in below industries

A.electric cable jacketing

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare parts

G.heat isolation

H.black colorant in rubber materials

I.plastic pipes

J.industries rubber products

K.fire fighting

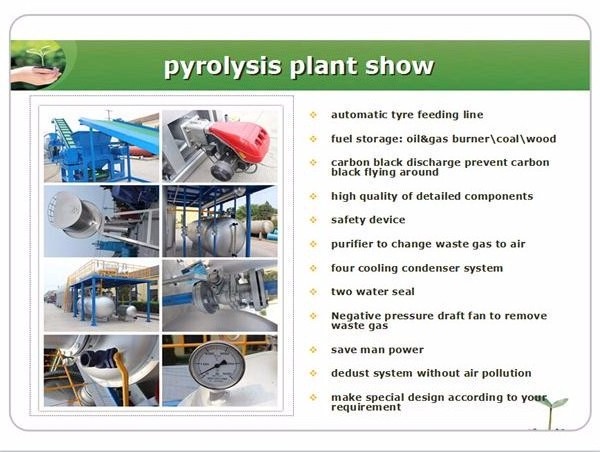

BENEFITS FROM ADVANCED PYROLYSIS TECH:

- Regaining energy and value from waste in the form of fuel and charcoal

- Reducing the plastic and tire pollution to land

- Recycling of plastics and tires which are Eco-friendly

- Commercially viable process

- End product oil is used as substitute to Furnace oil

- Perfect solution for Polymer waste management

- Raw material (waste tires, waste plastics) available

- Zero emission process: no harm to environment

- Less reaction time and more energy savings

- Plant is 'Energy self sufficient

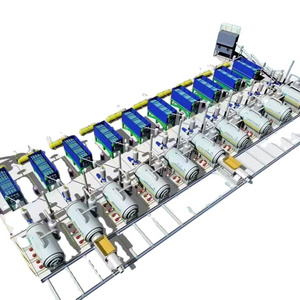

- Device composition

1. Delivery time- It will be 10-15 days after we receive the deposit.

2. Warranty- The warranty period for reactor and other parts except spare parts is 1 year.

wrong operation results of workers shall not be responsible by our company.

3. Installation and Training-Our company will send one technician for each set of machine for guiding your installation, testing the machine and training your workers.