- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Workshop

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DC

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Other

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Workshop

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DC

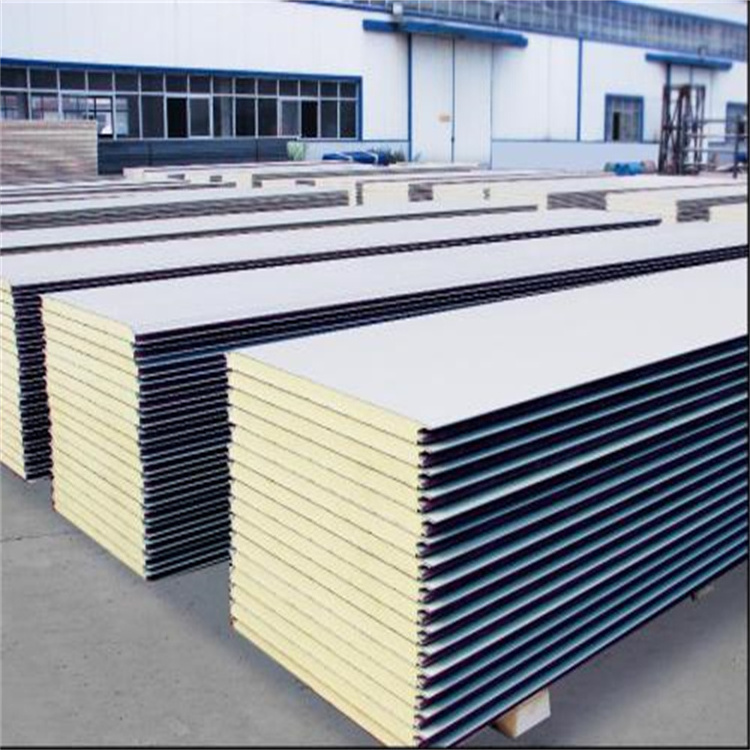

Introducing Sandwich Panels:

The Ultimate Solution for Structural Versatility

Sandwich panels revolutionize construction by offering a versatile, efficient, and durable solution for a wide array of applications. Comprising a core material sandwiched between two outer layers, typically made of metal, wood, or composite materials, these panels provide unparalleled strength-to-weight ratio, thermal insulation, and soundproofing properties.

Ideal for both residential and commercial projects, sandwich panels offer flexibility in design, enabling architects and builders to create innovative structures with ease. Whether used for roofing, wall cladding, or flooring, these panels offer exceptional durability, weather resistance, and energy efficiency.

With customizable options to meet specific project requirements, sandwich panels are the go-to choice for modern construction projects seeking superior performance and aesthetics. Embrace the future of construction with sandwich panels – where strength meets versatility.

Detailed introduction of Sandwich Panel

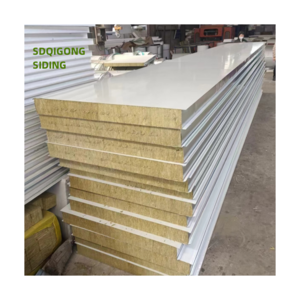

1.Specification for EPS sandwich panel:

|

Effective width |

Wall panel: 950mm 1150mm Roof panel: 960mm |

|

Length |

According to customer's request |

|

Materials |

Polystyrene foam board(EPS), Color steel sheet |

|

Structure |

Upper and lower layer: Color steel sheet |

|

Middle: polystyrene foam board |

|

|

Thickness |

Color steel sheet: 0.3-0.6mm

|

|

The polystyrene density |

8-20kg/m3 |

|

Conventional color |

Ocean blue, tephrosious |

|

Character |

Light in weight, heat insulation, water resistant, green and environmental |

|

Use |

various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

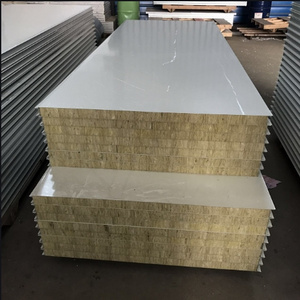

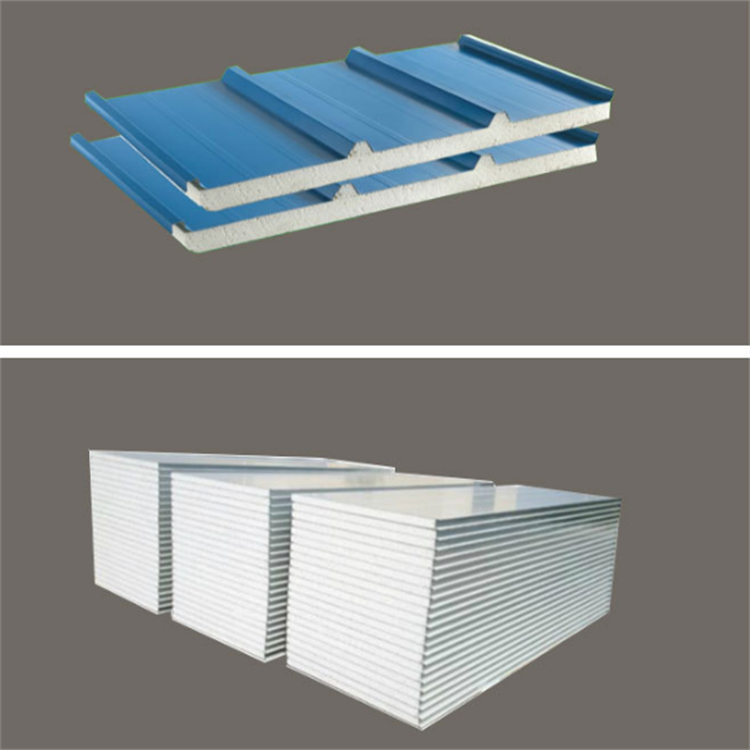

2. Common rockwool&glasswool sandwich panel

|

Effective width |

Wall panel: 950mm 1150mm Roof panel: 960mm |

|

Length |

According to customer's request |

|

Materials |

Rockwool&glasswool board, Color steel sheet |

|

Structure |

Upper and lower layer: Color steel sheet |

|

Middle:Rockwool&glasswool board |

|

|

Thickness |

Color steel sheet: 0.3-0.6mm

|

|

The polystyrene density |

50-80kg/m3 |

|

Conventional color |

Ocean blue, tephrosious |

|

Character |

Fireproof, heat insulation, water resistant, green and environmental |

|

Use |

various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

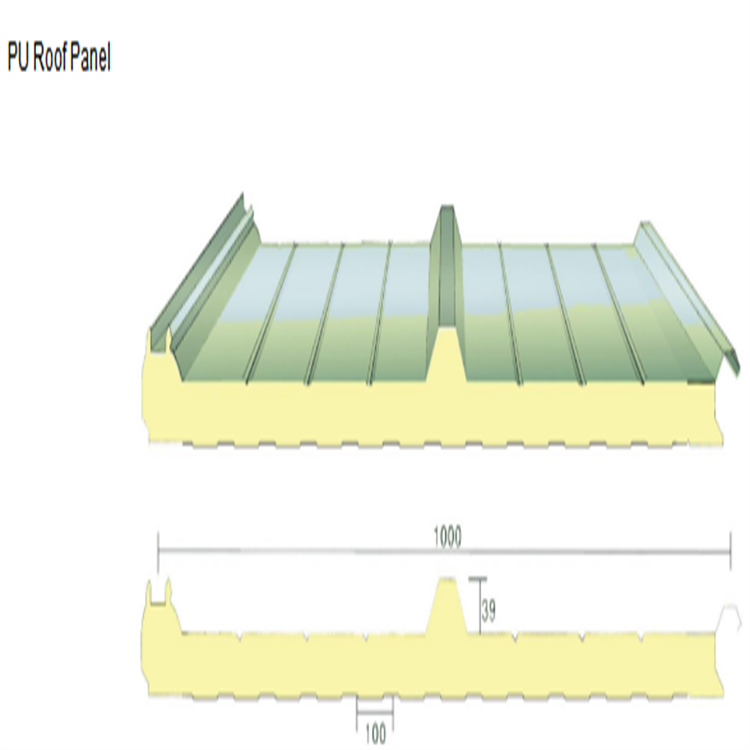

3. Specification for PUR/PIR sandwich panel:

Polyurethane sandwich panels are also known as anti-seepage sandwich roof panels, polyurethane rigid foam insulation panels, polyurethane composite panels, and PU panels. It is a double metal surface, single metal surface and non-metal surface composite panel with polyurethane rigid foam as the insulation layer. It is a kind of high-efficiency and energy-saving building envelope material with wide application and great potential, which can be applied to various building needs.

|

Effective width |

Wall panel: 1000mm Roof panel: 1000mm |

|

Length |

According to customer's request |

|

Materials |

Po,lystyrene foam board(EPS) Color steel sheet |

|

Structure |

Upper and lower layer: Color steel sheet |

|

Middle:polyurethane foam board |

|

|

Thickness |

Color steel sheet: 0.4-0.8mm

|

|

The polystyrene density |

38-42kg/m3 |

|

Conventional color |

Ocean blue, tephrosious |

|

Character |

Light in weight, heat insulation, water resistant, green and environmental |

|

Use |

various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

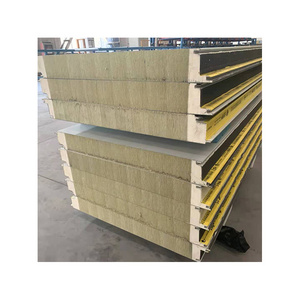

4. Specification for New rockwool&glasswool sandwich panel:

|

Effective width |

Wall panel: 1000mm Roof panel: 1000mm |

|

Length |

According to customer's request |

|

Materials |

Rockwool&glasswool board, Color steel sheet |

|

Structure |

Upper and lower layer: Color steel sheet |

|

Middle:Rockwool&glasswool board |

|

|

Thickness |

Color steel sheet: 0.4-0.6mm

|

|

The polystyrene density |

80-120kg/m3 |

|

Conventional color |

Ocean blue, tephrosious |

|

Character |

Fireproof, heat insulation, water resistant, green and environmental |

|

Use |

various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

Introducing Dragon Construction's Customizable Sandwich Panels: Elevating Your Steel Structure Buildings.

At Dragon Construction, we pride ourselves on delivering top-notch solutions for your steel structure buildings, and our range of sandwich panels is no exception. Our panels are meticulously crafted to enhance the performance and aesthetics of your projects, offering unparalleled versatility and reliability.

Whether you require superior thermal insulation, robust weather resistance, or exceptional soundproofing capabilities, our diverse selection of sandwich panels has you covered. From roofing to wall cladding, our panels seamlessly integrate with your steel structures, ensuring durability and efficiency.

What sets us apart is our commitment to customization. With Dragon Construction, you have the flexibility to choose from a variety of core materials, including polystyrene, polyurethane, and rock wool, tailored to meet your specific project needs. Our expert team works closely with you to understand your requirements and deliver solutions that exceed your expectations.

Experience the difference with Dragon Construction's sandwich panels – where quality, innovation, and reliability converge to elevate your steel structure buildings to new heights.

Q1. What is your terms of packing?

A: Generally, we pack our goods in bulk and put into the soft EPS for protection to save the container space. If you have the requests, we also make the iron pallet package.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

B:L/C etc

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 10 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.