- Product Details

- {{item.text}}

Quick Details

-

H Content (%):

-

0

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

RJXHOBBY

-

Model Number:

-

RJX-CFT

-

Working Temperature:

-

<200

-

Volatile:

-

0

-

Name:

-

high strength rectangular octagon square carbon fiber tube

-

Material:

-

100% Carbon Fiber Tube

-

Length:

-

Standard 1000mm

-

MOQ:

-

1

Quick Details

-

C Content (%):

-

Above 90%

-

S Content (%):

-

0

-

N Content (%):

-

0

-

H Content (%):

-

0

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

RJXHOBBY

-

Model Number:

-

RJX-CFT

-

Working Temperature:

-

<200

-

Volatile:

-

0

-

Name:

-

high strength rectangular octagon square carbon fiber tube

-

Material:

-

100% Carbon Fiber Tube

-

Length:

-

Standard 1000mm

-

MOQ:

-

1

Product Description

About Carbon Fiber :

Weaving material: 100% carbon Fiber Yarn

Carbon fiber made of polyacrylonitrile(PAN). We imported the carbon fiber yarn from Japan,it has been manufacturing

high-performance carbon fiber longer, providing a number of high-quality,stable products.With its excellent characteristics.

Composite materials are contribution significantly to wide-ranging fields including aerospace,industrial, sport/leisure,etc.

Carbon Fiber products widely applied to: Sailing, Yacht, Sports Equipment, Medical Devices, Telecommunications, Drones,RC helicopter,UAV, Intelligent Industrial Robot, New-energy Car,etc

We use Drum Hot Pressing(DHP) technique to make carbon fiber sheet. It makes more precise thickness than Flat Pressing techniques.

Drum high pressing and 100% full carbon material make the material more lighter, stronger and smoothly. And smaller tolerance.

Carbon fiber made of polyacrylonitrile(PAN). We imported the carbon fiber yarn from Japan,it has been manufacturing

high-performance carbon fiber longer, providing a number of high-quality,stable products.With its excellent characteristics.

Composite materials are contribution significantly to wide-ranging fields including aerospace,industrial, sport/leisure,etc.

Carbon Fiber products widely applied to: Sailing, Yacht, Sports Equipment, Medical Devices, Telecommunications, Drones,RC helicopter,UAV, Intelligent Industrial Robot, New-energy Car,etc

We use Drum Hot Pressing(DHP) technique to make carbon fiber sheet. It makes more precise thickness than Flat Pressing techniques.

Drum high pressing and 100% full carbon material make the material more lighter, stronger and smoothly. And smaller tolerance.

|

Name

|

RJXHOBBY high strength carbon fibre tube hexagonal rectangular octagon square carbon fiber tube

|

|

Material

|

100% T300 carbon fiber

|

|

Surface

|

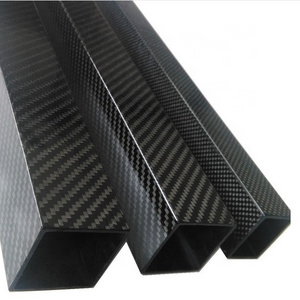

3K twill/3k plain, glossy/matte finished

|

|

Process

|

Autoclave technology: perfect surface, smoothly, flawless.

|

|

Feature

|

High strength & high Modulus & Corrosion Resistant

|

|

Why Choose Us:

|

* Rich experience: devote carbon fiber industry over 15 years.

* CNC service, Custom size, OEM & ODM. * High end material: 100% full Japan carbon fiber. * Autoclave technology: perfect surface, smoothly, flawless. * Strict thick tolerance: ±0.05mm. * Fast delivery: 90% products in-stock, CNC frames delivery within 24 hours. |

|

|

|

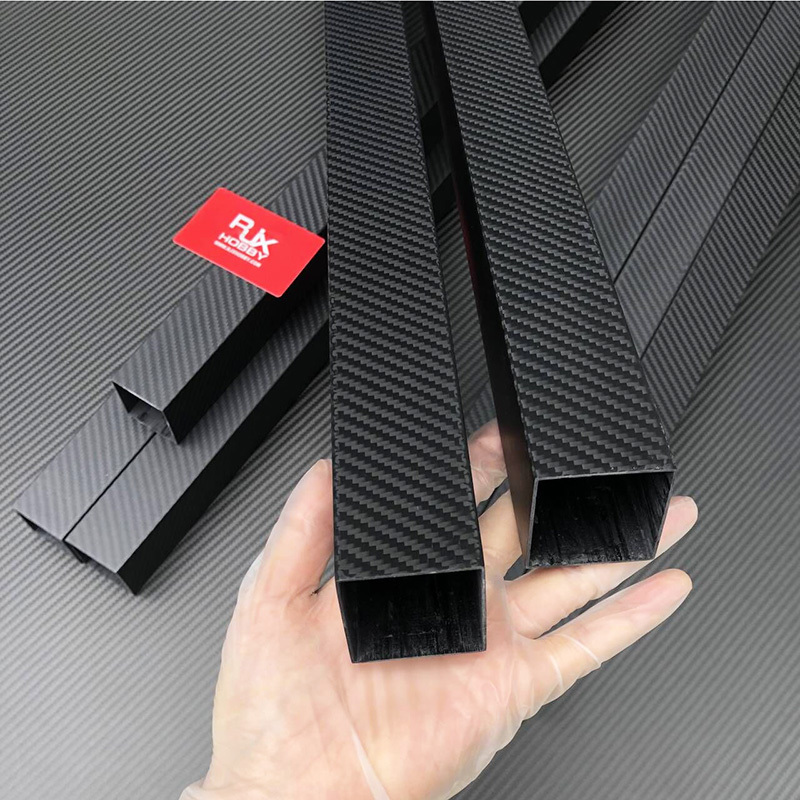

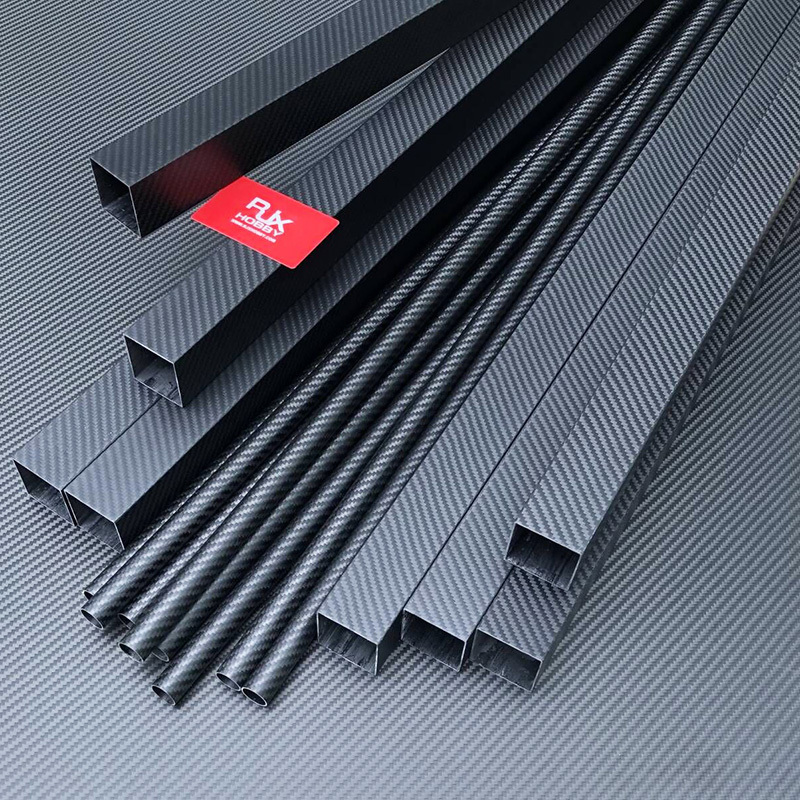

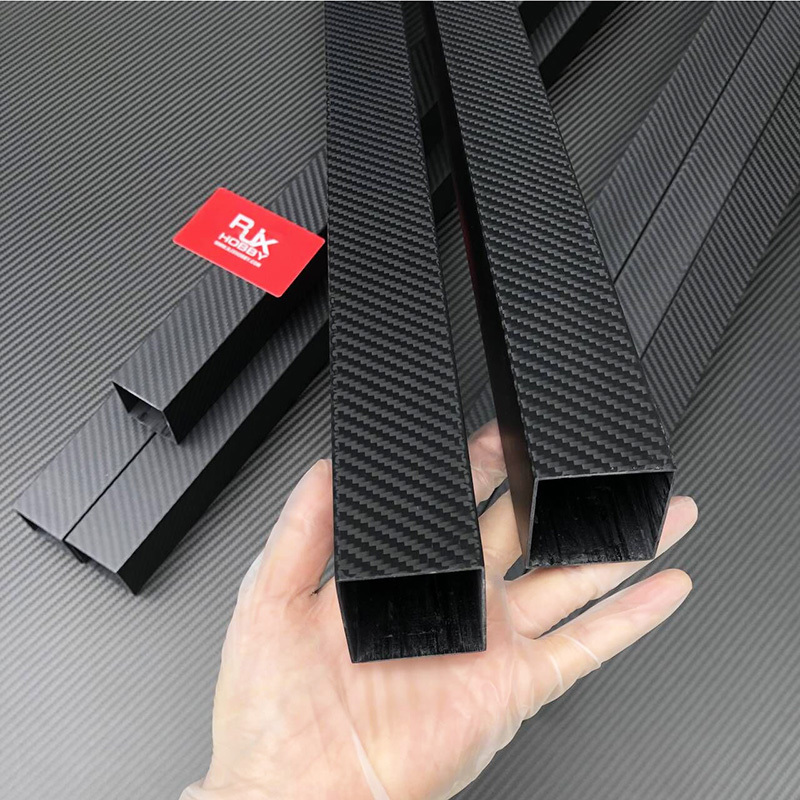

Product Show

3K matte finish carbon fiber square tubes

3K Glossy finish carbon fiber square tubes

Square tube: 15x15mm/ 20x20mm/25x25mm/30x30mm/40x40mm/45x45mm/50x50mm/60x60mm/80x80mm

Round tube: 6mm-300mm diameters

Octagonal tube: 20x30mm/25x38mm

Custom carbon fiber tube Made with 100% carbon fiber.

We also provide custom cnc cutting & drilled carbon tubes,w

elcome send your design drawings in type of DXF/DWG to quote.

Recommend Products

Why Choose Us

RJX was established in 2006, after years of development, we have professional R&D, management, sales teams and excellent production team. We own a standard factory with 20,000 square meters. Our products line covers sheet, pipe and customized products etc. The production process has also developed from a single lamination process to coil, lamination, molding, bag pressing, hand laying, vacuum guide-assisted molding and other processes, basically covering all processes of composite materials such as carbon fiber.

Our company has 4 pipe production lines, 2 vacuum flow guide auxiliary production lines, 2 coating lines, 1 printing line, 1 automatic cloth cutting equipment, 8 hot pressing molding equipment, 50+ CNC equipment, 3 precision grinding equipment, 1 cold storage warehouse and many auxiliary production equipment. We can design, develop and produce various carbon fiber products according to customers' requirements.

Company Certificate

Application

FAQ

Q1. Can I have a factory visit?

A: Warmly welcome! International Airport both convenience. If you come, please feel free to contact us, we'll pick you up!

Q2. Is sample order accepted?

A: It's no problem, we welcome sample order to test and check quality. Mixed samples also acceptable.

Q3. Is mixed batch of different products accepted?

A: Sure, wholesales of different products are accepted, no limit of different specification.

Q4. How do you ship the goods and how long does it take arrive?

A: We usually ship by FedEx, TNT, DHL, UPS... And if too heavy by sea is economic choice. Delivery time according to stock goods or customed order.

Q5. Do you have MOQ for your products?

A: That's according to the products, usually sample order 1 pcs is accepted.

Q6: What's the lead time?

A: Stock products: within 24 hours;

CNC service: 1~ 2 days;

Custom special size: usually 5~7 days, depening on the quantity.

A: Warmly welcome! International Airport both convenience. If you come, please feel free to contact us, we'll pick you up!

Q2. Is sample order accepted?

A: It's no problem, we welcome sample order to test and check quality. Mixed samples also acceptable.

Q3. Is mixed batch of different products accepted?

A: Sure, wholesales of different products are accepted, no limit of different specification.

Q4. How do you ship the goods and how long does it take arrive?

A: We usually ship by FedEx, TNT, DHL, UPS... And if too heavy by sea is economic choice. Delivery time according to stock goods or customed order.

Q5. Do you have MOQ for your products?

A: That's according to the products, usually sample order 1 pcs is accepted.

Q6: What's the lead time?

A: Stock products: within 24 hours;

CNC service: 1~ 2 days;

Custom special size: usually 5~7 days, depening on the quantity.

Contact us directly to get fast reply ↓↓↓ : )

Hot Searches