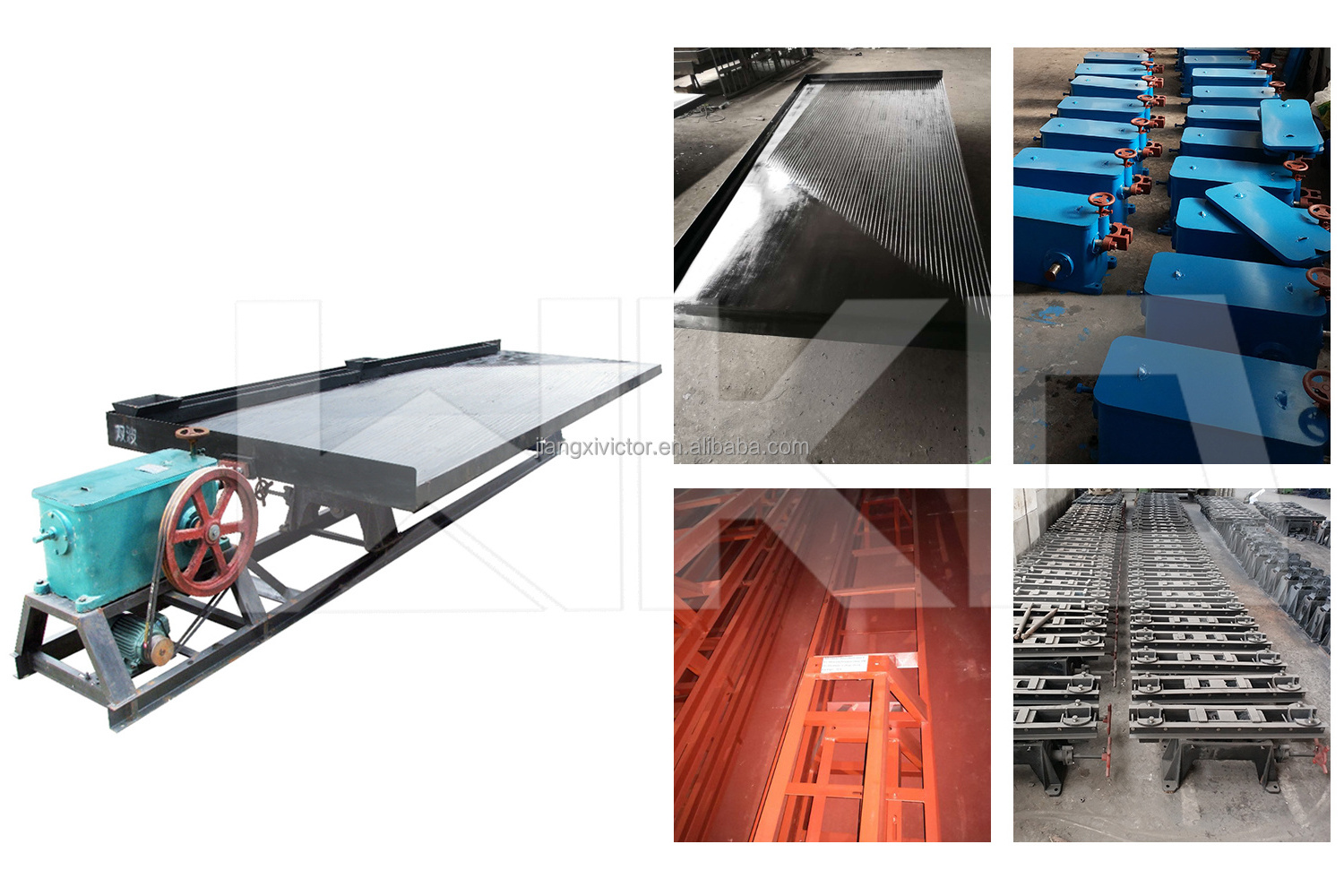

1. Ore Feeding Mouth 2. Stroke Adjusting Device

3. Ore Feeding Chute

4. Water Feeding Mouth

5. Water Feeding Chute

6. Table Surface

7. Concentrates Discharging Area 8. Tailing Discharging Area

9. Horizontal Support

10. Horizontal Adjustment Wheel

11. Table Support

12. Knife-Type Support

13. Stand

14. Driving Unit 15. Motor Support

16. Swing Adjusting Device

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1530*500*660mm

-

Weight:

-

240 KG

-

Product name:

-

small gold shaker table

-

Material:

-

Fiberglass

-

Feeding size:

-

0.0074-2mm

-

Capacity:

-

0.1-0.2t/h

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Separatoion

-

After sale service:

-

Video Technical Support

-

After-sales Service Provided:

-

Online support

-

Keywords:

-

gold wilfley shaking table

-

Application area:

-

fine gold

Quick Details

-

Production Capacity:

-

80-95%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

WKD

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1530*500*660mm

-

Weight:

-

240 KG

-

Product name:

-

small gold shaker table

-

Material:

-

Fiberglass

-

Feeding size:

-

0.0074-2mm

-

Capacity:

-

0.1-0.2t/h

-

Installation:

-

Engineer Guide

-

Usage:

-

Mining Separatoion

-

After sale service:

-

Video Technical Support

-

After-sales Service Provided:

-

Online support

-

Keywords:

-

gold wilfley shaking table

-

Application area:

-

fine gold

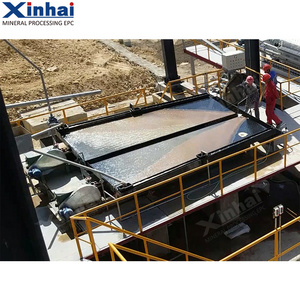

Product Overview

Gold Shaker Table

Shaking table is designed to wet gravity-based separation of minerals and other granular materials.

There are many applications where the concentrating table is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

6-S shaking bed is one of the main equipment for gravity classification, which is widely applied in the classification of tungsten, tin, tantalum, columbium and other rare metal and precious metal ore. shaking bed is designed for wet gravity-base separation of mineral and other granular materials. It is effective in processing precious and base metal, rare and non-metallic minerals.

There are many applications where the concentrating table is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

6-S shaking bed is one of the main equipment for gravity classification, which is widely applied in the classification of tungsten, tin, tantalum, columbium and other rare metal and precious metal ore. shaking bed is designed for wet gravity-base separation of mineral and other granular materials. It is effective in processing precious and base metal, rare and non-metallic minerals.

PRODUCT SPECIFICATIONS

|

Model

|

LYS4500

|

LYS3000

|

LYS2100

|

LYS1100

|

|

Screen Size mm

|

4500x1850x1560

|

3000x1490x1360

|

2100x1050x850

|

1100x500x430

|

|

Stroke length mm

|

10-30

|

6-30

|

12-28

|

9-17

|

|

Frequency T/min

|

240-420

|

210-320

|

250-450

|

280-460

|

|

Horizontal slope °

|

0-5

|

0-10

|

0-8

|

0-10

|

|

Feeding Density %

|

10-30

|

10-30

|

10-30

|

10-30

|

|

Coarse

Feeding Size Fine

Slime

|

2-0.5 mm

|

2-0.5 mm

|

2-0.5 mm

|

2-0.5 mm

|

|

|

0.5-0.074mm

|

0.5-0.074mm

|

0.5-0.074mm

|

0.5-0.074mm

|

|

|

0.074-0.037mm

|

0.074-0.037mm

|

0.074-0.037mm

|

0.074-0.037mm

|

|

Coarse

Capacity tph Fine

Slime

|

1-2.5

|

0.6-1.5

|

0.4-0.8

|

0.1-0.2

|

|

|

0.8-1.2

|

0.3-0.8

|

0.2-0.5

|

0.05-0.1

|

|

|

0.3-0.9

|

0.2-0.6

|

0.1-0.4

|

0.03-0.05

|

|

Water consumption tph

|

0.4-0.7

|

0.3-1.5

|

0.2-1

|

0.1-0.5

|

|

Motor KW

|

1.1

|

1.1

|

1.1

|

1.1

|

|

Size mm

|

5600×1850×860

|

4075×1320×780

|

3040×1050×1020

|

1530×500×800

|

Details Images

Packing and Delivery

FEATURES AT A GLANCE

Shaking Table Concentrator

Working Principle

Shake table is on the lean table board with raffles. The ore material is fed in by the feeding chute upper table board; meanwhile, the water is fed by water feeder transversely. Under the impact of vibrating wave, the materials go on vertical and horizontal movement as per the different proportion and granularity. The ore material with different proportion and granularity move down in laddershipped state along with their own movement, then discharge from the fine concentrate end and tailings end,

finally they are separated out to fine concentrate, middle concentrate and tailings.

Successful Project

Hot Searches