- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

0.35 0.5 0.7

-

Product Name:

-

press brake tooling

-

Mould material:

-

customized

-

Application:

-

Hydraulic press brake

-

Feature:

-

durable

-

Function:

-

folding

-

Hardness:

-

47±0.2HRC

-

Tolerance:

-

±0.002mm

-

Packing:

-

Wooden Case Packing

-

Length:

-

2500/3200/4000/6000

-

Port:

-

Shanghai

Quick Details

-

Shaping Mode:

-

Forging Mould

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RONGWIN

-

Model Number:

-

0.35 0.5 0.7

-

Product Name:

-

press brake tooling

-

Mould material:

-

customized

-

Application:

-

Hydraulic press brake

-

Feature:

-

durable

-

Function:

-

folding

-

Hardness:

-

47±0.2HRC

-

Tolerance:

-

±0.002mm

-

Packing:

-

Wooden Case Packing

-

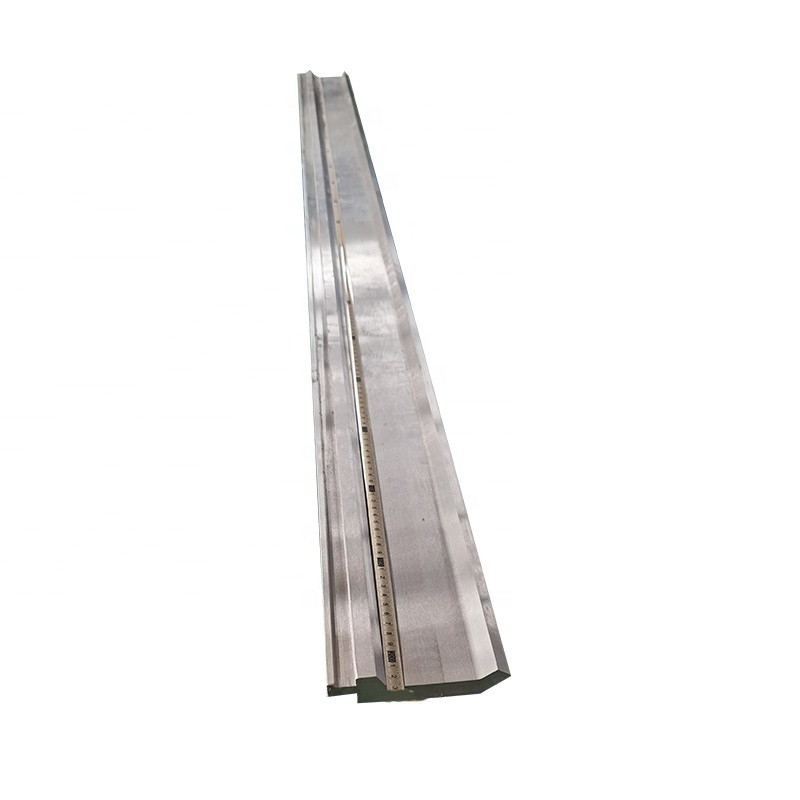

Length:

-

2500/3200/4000/6000

-

Port:

-

Shanghai

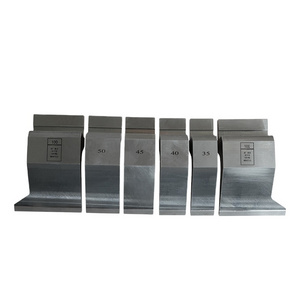

Product Description

Background conditions:

In the process of bending, due to the influence of mold, bending pressure, and other factors, the plate often produces indentation, especially aluminum plates, and stainless steel plates, which will seriously affect the appearance of the product. To avoid or reduce these indentations, many manufacturers choose to carry out secondary processing, regrinding after bending or painting the plate. Some manufacturers coat the plate before bending to avoid indentation. However, these operations are not only time-consuming and labor-consuming but also have little effect.

RONGWIN

bending film

has been verified by tests, in addition to the surface quality, it also greatly improves the service life. The bending protective film is used as a buffer between the workpiece and the lower mold, to prevent the workpiece from being indented during bending. When using, just put the bending film on the lower mold of the bending machine.

Detailed Images

Features of Bending Anti-Indentation Protective Film

1. Strong wear resistance

2. Strong tear resistance

3. Excellent bending performance

4. High tensile strength and elongation at break

5. Low temperature and high-temperature resistance +50℃~150℃

6. Low long-term compression deformation rate

7. Resistant to oil, lubricating oil, and aliphatic hydrocarbon solvents

8. Resistant to oxygen and ozone, aging resistance

Related Products

For non-indentation bending, our company offers a variety of solutions to choose from

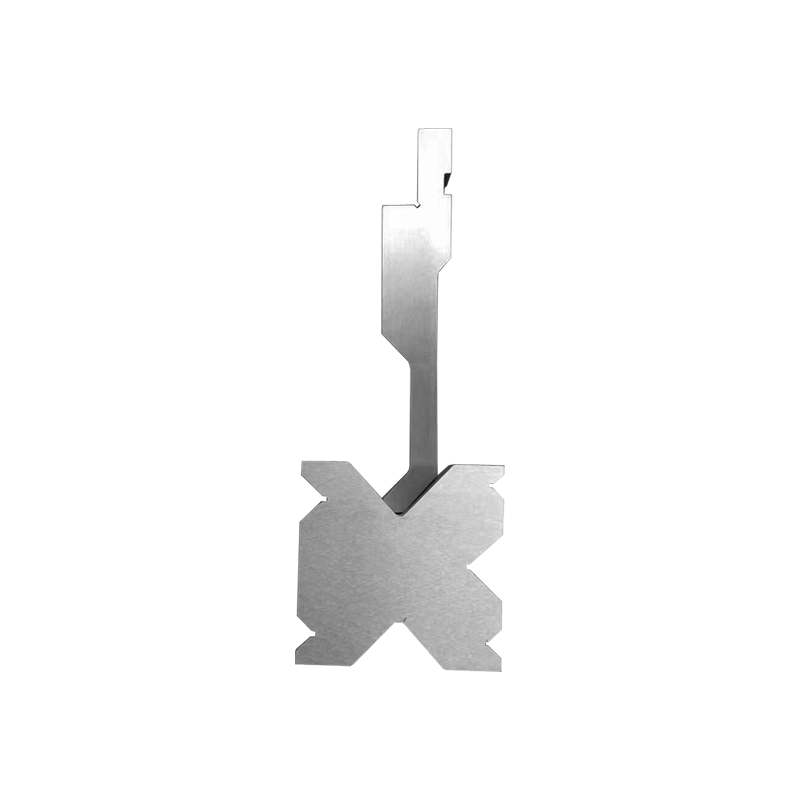

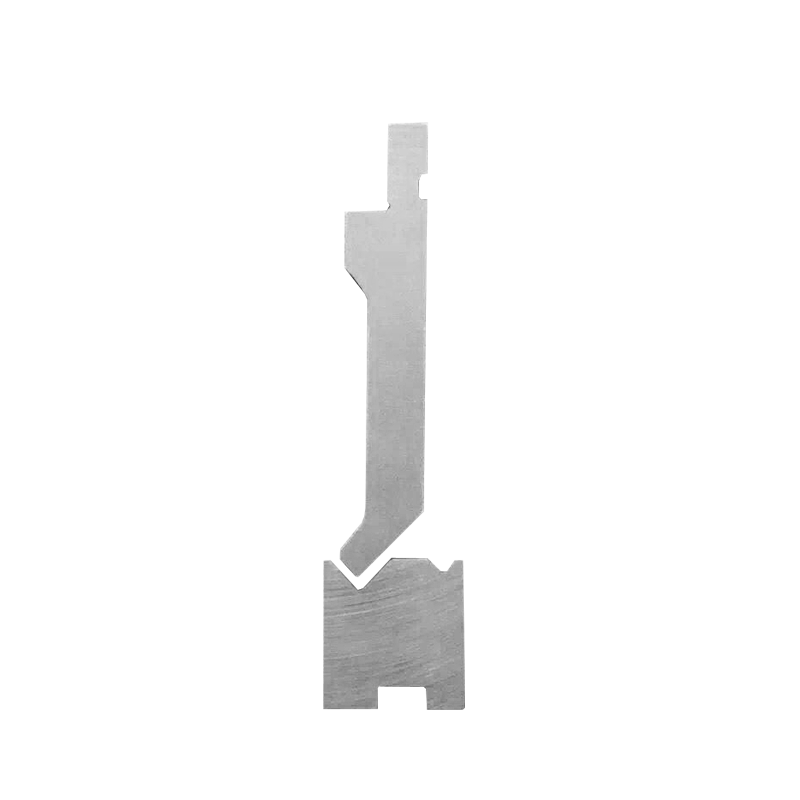

When the sheet is bent, the V-groove roller is rotated to reduce the friction on the sheet, thereby protecting the scratches on the surface of the sheet.

The main working principle of the rolling V-shaped die is that the upper die falls, the rotating shaft rotates, and the turning

plate is turned. It is precisely because the turnover of the turnover plate makes the workpiece fully in contact with the lower die,

without any sliding range, to avoid indentation.

plate is turned. It is precisely because the turnover of the turnover plate makes the workpiece fully in contact with the lower die,

without any sliding range, to avoid indentation.

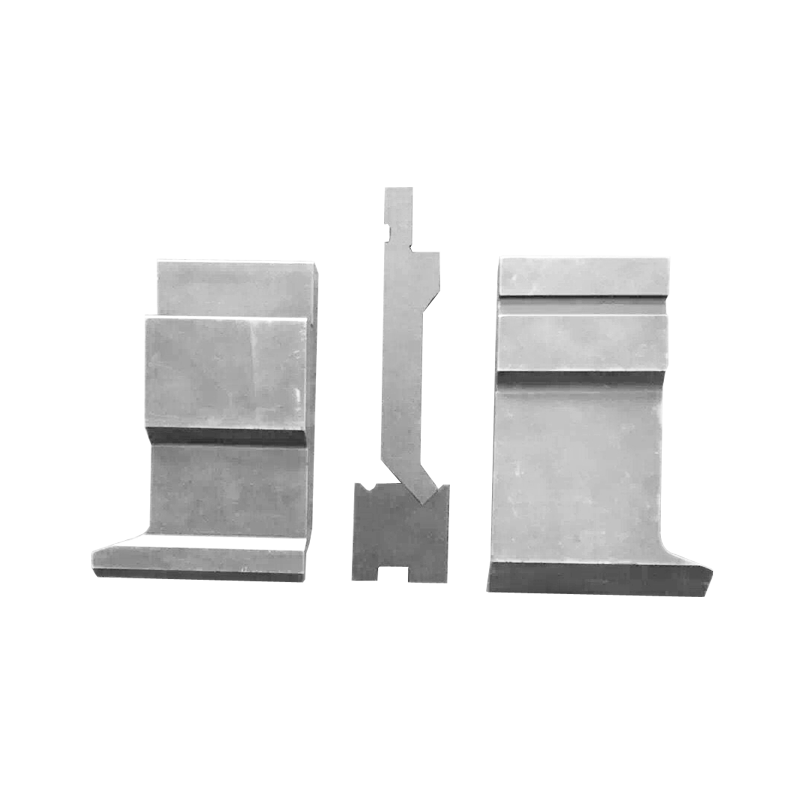

Polyurethane strip mold

The replaceable rubber strip v-mold is to open a gap on both sides of the common v-mold and insert the rubber strip into the gap.

In the bending process, the plate contacts the rubber strip. The hardness of rubber strip is far lower than that of common lower

die, to avoid indentation.

In the bending process, the plate contacts the rubber strip. The hardness of rubber strip is far lower than that of common lower

die, to avoid indentation.

Recommend Products

Packing&Shipping

1.PE film or Kraft paper - keep air/water/humid away,thus rust-proofing.

2.Bubble Wrap - increases the impact resistance ability.

3.Rubber Slip or Corrugated Angle - gives special care to knife edges.

4.Wood Screws crates - makes opening easier without damaging the crates.

5.Corrugated boxes or Wooden crates - provide superior protection & stack ability.

|

Quantity (Roll)

|

<20

|

20-50

|

≥50

|

|

Est. Time (Days)

|

7

|

15

|

30

|

Company Introduction

Naijing Rongwin machinery technology co.,ltd

is located in Zijin Technology Center, Lishui Economic Development

Zone,Nanjing,Jiangsu,China (Mainland). Our company is a comprehensive enterprise integrating production and sales. The main products are bending machine and other mechanical equipment, longitudinal shear blades, hobbing scissors, rubber-coated spacers, carbide blades, bending machine die, etc.It is widely used in metallurgy, paper making, printing, forestry hardware, plastics, rubber, metal and other industries.The company's products have won high praise from customers all over the world with high quality and preferential prices. Our company has a strong research and design force, constantly absorbing advanced technology and experience at home and abroad. After years of development, the company with strong technical force, excellent management system, excellent equipment, perfect testing methods, to bring customers real benefits, earlier delivery date and quality assurance. Our company's consistent pursuit is to improve product quality, take science and technology as the spirit, take quality as the guarantee, seek development with products, survive with reputation, perfect quality management system and excellent and thoughtful after-sales service to serve you wholeheartedly.

FAQ

Hot Searches