- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

Motor Customized

-

Power:

-

20-30KW

-

Weight (KG):

-

8000

-

Keywords:

-

continuous carbonization furnace

-

Advantage:

-

high capacity,no smoke

-

Carbonization time:

-

20minutes

-

Carbonizing fuel:

-

Biomass Gas

-

Applicable raw materials:

-

Palm Fiber, rice husk, peanut, etc.

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Effective Volume:

-

5-10CMB

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

Motor Customized

-

Power:

-

20-30KW

-

Weight (KG):

-

8000

-

Keywords:

-

continuous carbonization furnace

-

Advantage:

-

high capacity,no smoke

-

Carbonization time:

-

20minutes

-

Carbonizing fuel:

-

Biomass Gas

-

Applicable raw materials:

-

Palm Fiber, rice husk, peanut, etc.

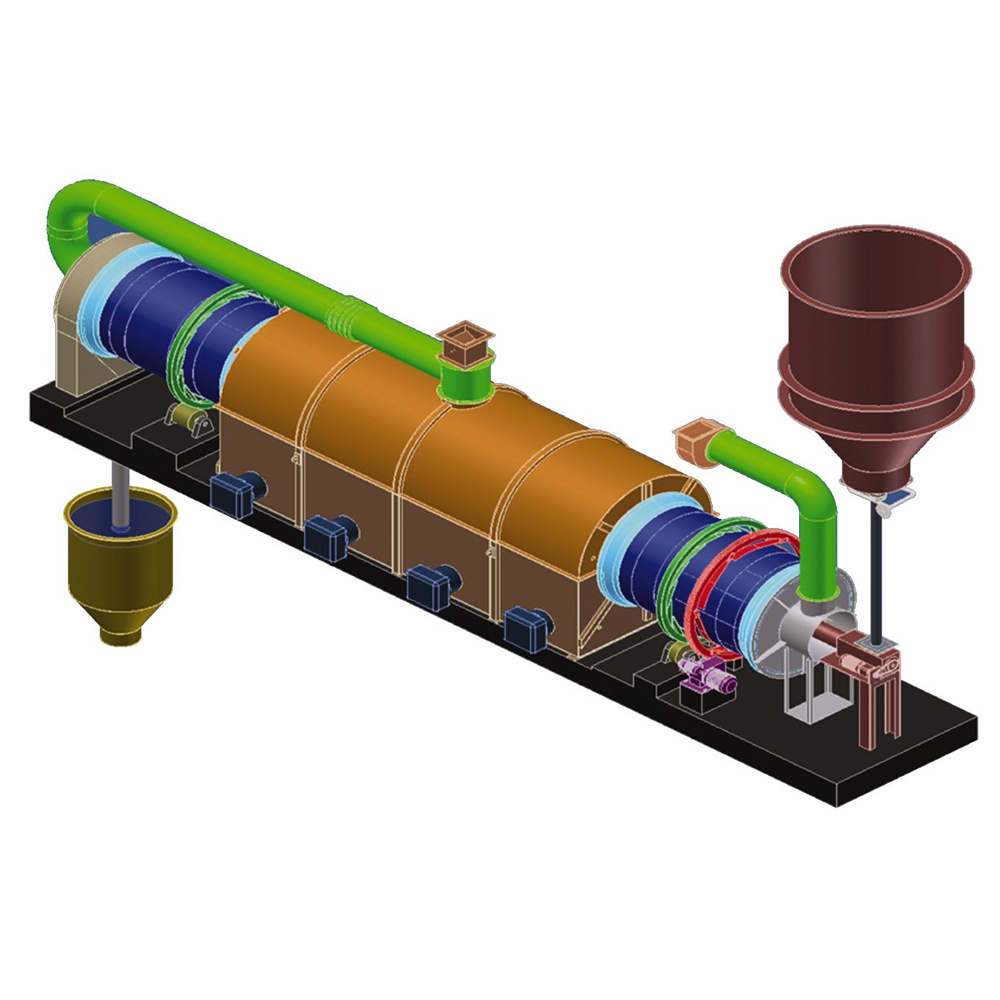

Rotary Carbonization kiln Furnace Activated Charcoal Making Machine

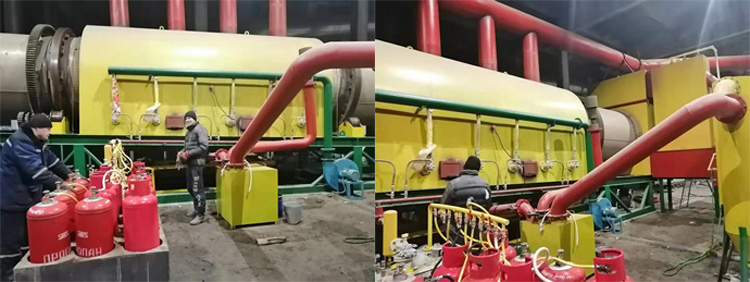

Continuous carbonization furnace is the newest high production equipment in my company, at present,thecarbonization equipment on the market has small production,but the area is larger, therefore, after several experts of research and development,my company has designed horizontal high-throughput coking equipment,the production is high, high utilization rate of thermal efficiency,energy saving,environmental protection, smokeless, real implementation of smoke-free type production.

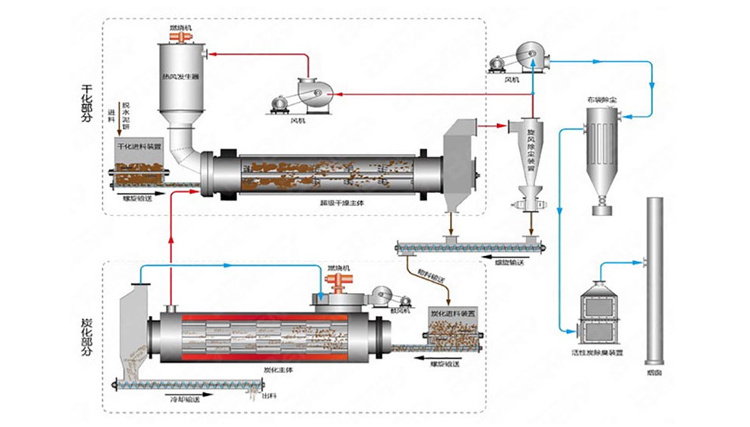

working principle:

Burning the raw material inside of the gasification furnace (as sawdust, shell, Palm shell, husk, straw, wood scrap etc.), the produced flue gas in pipeline within after spray pour, cooling purification, became combustible gas (carbon monoxide, methane, ethane,), as early carbonization of heat, heating and carbonizing the raw material inside of the carbonization furnace(as mechanism core rod, abandoned logs, bark, coconut shell, life garbage,etc.)

When the temperature reached to 300 degrees Celsius, carbonization furnace starting carbonizing of raw materials, producing smoke; flue gas become into a combustible gas after spray pour, cooling purification by the cooling purification system, continue carbonizing, then gasifier stop working.

1

, continuous carbonized machine just started (feeding first )heating, needs heat source heating carbonization furnace.

(1) One kind of using reverberatory furnace to produce heat flow for burning carbonization, achieve the goal of heating carbonization.

(2) The other is adopting gasifier, lit sawdust by gasifier and gasification of combustible gas burning carbonization, reach the purpose of heating carbonization, (gasification of sawdust after the carbonization of coal powder output device be carbonized charcoal powder, in addition to combustible gas through the wood tar recycling equipment recycling)

2,To reach a certain temperature, inside the combustible gas dust separation by dust separator, dust separation of combustible gas and then through the wood tar recovery unit.

3,After waiting for coking heating produced gas, at that time the furnace heating or gasifier and gas plant stop working, preliminary heating equipment work over.

4,After carbonized about 2 to 3 hours, (different temperature with time) ,carbon powder from carbonized slowly into coking coal powder and flowed from the cooler, cooler equipment production on a normal continuous uninterrupted.

5, wood tar is a kind of important chemical raw material, contains more than 300 kinds of chemical elements in the wood tar, the device will automatically discharge wood tar.

Generally speaking, almost all kinds of raw materials are appropriate for this furnace, such as, plant straw, bamboo charcoal, coconut shell, sawdust, wood, rice husk, tree bark, jute stick, palm shell and so on. But there is a little limitation. That is if the diameter of the raw materials is too large, they need be shredded. Here, the shredder will be used to shred them into small pieces. Yes, we sell various types of shredder as well.

1.None stoping,working for 24 hours

2.Large capacity,one day can reach to 7.2 tons

3.Environmental protection,burn the furnace smoke itself,so no smoke go out

4.Energy saving,burn smoke as power.

5.Make sawdust ,rice hush,coconut shell,,,ect into charcoal timely.

6.Sawdust carbonization furnace energy is recycle using.