- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DH

-

Model Number:

-

DH-2024-321

-

Use:

-

Building/sandblasting/polishing/abrasive

-

Product name:

-

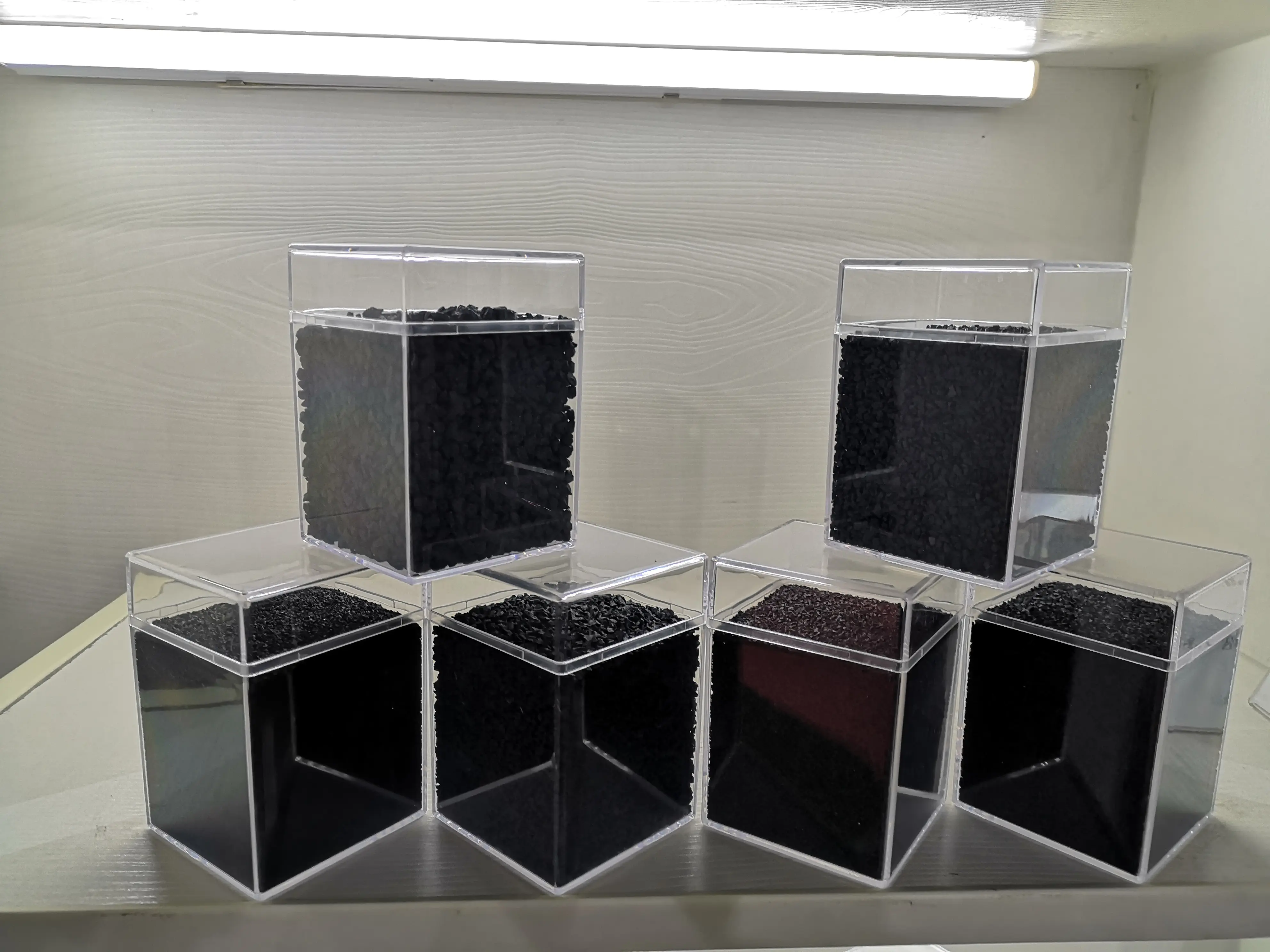

Black Fused Alumina

-

Application:

-

Abrasive blasting polishing wheel

-

Sample:

-

Sample Provided

-

Size:

-

24 60 120 180 240 400mesh

-

Hardness:

-

8.0-9.0 Mohs Scale

-

True density (g/cm3):

-

≥3. 50

-

Material:

-

Al2O3

-

Al2O3:

-

65-85%

-

Fe2O3:

-

6-12%

-

SiO2:

-

10%

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

3-5mm 24 60 120 180 240 400mesh

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DH

-

Model Number:

-

DH-2024-321

-

Use:

-

Building/sandblasting/polishing/abrasive

-

Product name:

-

Black Fused Alumina

-

Application:

-

Abrasive blasting polishing wheel

-

Sample:

-

Sample Provided

-

Size:

-

24 60 120 180 240 400mesh

-

Hardness:

-

8.0-9.0 Mohs Scale

-

True density (g/cm3):

-

≥3. 50

-

Material:

-

Al2O3

-

Al2O3:

-

65-85%

-

Fe2O3:

-

6-12%

-

SiO2:

-

10%

Black corundum, also known as low aluminum corundum, is in the electric arc furnace, the bauxite melting and produced a kind α-Al2O3 and iron spinel as the main mineral phase of the gray-black crystals, which is characterized by the low content of

Al2O3,and a certain amount of Fe2O3 (10% or so) exists, and thus has a moderate hardness, high toughness, high temperature resistance,thermal stability of the performance of the characteristics of the state. It is mostly used for free grinding, such as polishing and rough grinding before plating of products, mainly used for polishing and sandblasting of stainless steel, metal products,optical glass, bamboo and wood products, and it is a novel abrasive for manufacturing resin grinding wheels, cutting discs, and abrasive cloth.

Al2O3,and a certain amount of Fe2O3 (10% or so) exists, and thus has a moderate hardness, high toughness, high temperature resistance,thermal stability of the performance of the characteristics of the state. It is mostly used for free grinding, such as polishing and rough grinding before plating of products, mainly used for polishing and sandblasting of stainless steel, metal products,optical glass, bamboo and wood products, and it is a novel abrasive for manufacturing resin grinding wheels, cutting discs, and abrasive cloth.

|

Name

|

Black corundum

|

|

Commonly used specification

|

Particle size of sand:3-5mm F:16,20,24,30,36,46,60,80,100,120,150,180,200,320

|

|

proportion of appearance

|

3.5g/cm3 Black granular.

|

|

raw materials

|

The bauxite in electric arc furnace smelting and become a kind of is given priority to with alpha AL2O3 and spinel mineral phase-colored crystals.

|

|

production process

|

Raw material sorting-electrolytic refining - crushing - in addition to the iron magnetic separation-screening-physical and chemical inspection-finished product packaging-warehousing

|

|

performance feature

|

Basic particle concentration, low linear expansion coefficient, good toughness, high grinding ratio.

|

|

Use

|

Stainless steel, metal, glass, wood products sand blasting, polishing, grinding wheel, cutting slices, sandpaper.

|

|

indicators

|

AL2O3 content is 85%, SiO2 content 5-8%, Fe2O3 content of 6-9%, content of TiO2 2-4%, true density of 3.5 g/cm after, the highest melting point temperature 1850 , 2050 1600 when the linear expansion coefficient of 7-9.

|

1. Metal and glass polishing.

Black corundum is used for polishing and sandblasting of stainless steel, metal products, optical glass, bamboo and wood products, etc. It can improve the finish of the processed parts, and is suitable for the bottom polishing of parts before plating, as well as the polishing of aluminum products.

2. Wear-resistant material.

Because of its high hardness and wear resistance, black corundum can be used for laying wear-resistant and anti-skid road surface,bridge deck, parking lot,etc. It is especially suitable for areas requiring high wear resistance such as sharp curves and

stee slopes.

3. Resin abrasives.

Black corundum can be used to make abrasives such as resin grinding wheels, resin cutting blades, resin abrasive discs, ultra-thin discs, etc. These abrasives are used in industry for grinding and polishing of metals, wood and other materials.

4.Coated abrasives.

Black corundum is compounded with brown corundum or calcined brown corundum to make coated abrasives, which are suitable for polishing wood, metal, etc.

5. Fiber polishing wheel.

Black corundum is used to make fiber polishing wheels, suitable for grinding and polishing of various workpieces.

6. Conductive material.

Specially treated black corundum has excellent electrical conductivity and can be used to make high-performance conductive materials.

2. Wear-resistant material.

Because of its high hardness and wear resistance, black corundum can be used for laying wear-resistant and anti-skid road surface,bridge deck, parking lot,etc. It is especially suitable for areas requiring high wear resistance such as sharp curves and

stee slopes.

3. Resin abrasives.

Black corundum can be used to make abrasives such as resin grinding wheels, resin cutting blades, resin abrasive discs, ultra-thin discs, etc. These abrasives are used in industry for grinding and polishing of metals, wood and other materials.

4.Coated abrasives.

Black corundum is compounded with brown corundum or calcined brown corundum to make coated abrasives, which are suitable for polishing wood, metal, etc.

5. Fiber polishing wheel.

Black corundum is used to make fiber polishing wheels, suitable for grinding and polishing of various workpieces.

6. Conductive material.

Specially treated black corundum has excellent electrical conductivity and can be used to make high-performance conductive materials.

25kg or 50kg per bag,or special pakcing requirement is acceptable.

Henan Dahua New Materials Co., LTD.,

located in Xing yang City, Henan Province, the company adheres to the development strategy of "science and technology Xing factory", advanced production equipment, strong technical force, complete testing equipment, stable product quality, and the ability to independently develop and produce new products in the industry. The company's quality assurance system is perfect,strict implementation of ISO9001 standards, product performance is stable, safe and reliable. The company vigorously introduce advanced professional production equipment and automatic production line,manufacturing by the majority of customers benefit products, we with stable quality, first-class service, reasonable prices.Welcome domestic and foreign merchants to negotiate with the factory.

Hot Searches