- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

5600*1500*2100

-

Weight:

-

4500 kg

-

Advantage 1:

-

Easy operate

-

Advantage 2:

-

Fast speed

-

Advantage 3:

-

Onsite installation

-

Advantage 4:

-

Long warranty

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

60 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

5600*1500*2100

-

Weight:

-

4500 kg

-

Advantage 1:

-

Easy operate

-

Advantage 2:

-

Fast speed

-

Advantage 3:

-

Onsite installation

-

Advantage 4:

-

Long warranty

Product Description

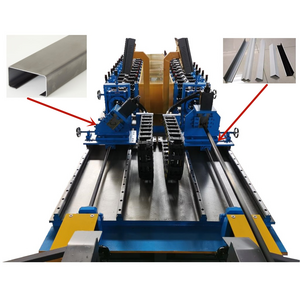

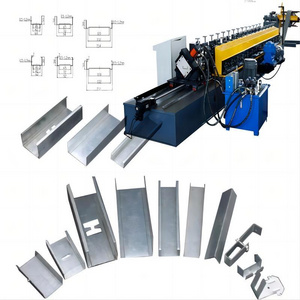

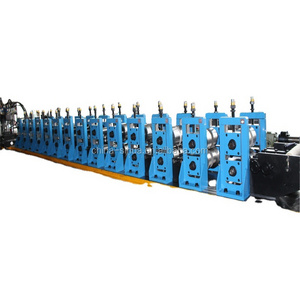

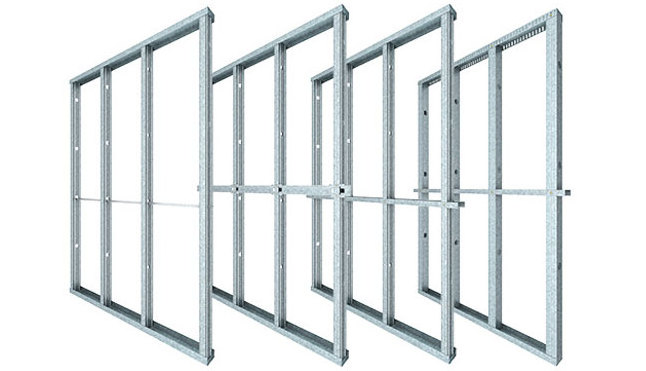

stud and track drywall C U channel roll forming machine

The light steel keel is a building metal skeleton that is rolled by a cooling process by high-quality continuous hot-dip aluminum zinc strip. The shape decoration of the finished non-loaded wall made of paper gypsum boards, decorative gypsum boards. Suitable for modeling decorations of a variety of building roofs, internal and external walls of the building and the base materials of the hooded ceiling.

Products Display

Why use this machine ?

1. Dry operation, safety, construction, and self-destructive division space, it is easy to remove. Can save manually, speed up the construction speed.

2. Light weight and strength can meet the needs of use. It is a very good partition with two light gypsum boards.

3. Chemical physical properties are stable, dry moisture absorbing gas, small telescopic deformation

4. Decorative effect. The surface layer of the gypsum board can be compatible with a variety of surface layer decorative materials to meet the decoration requirements for large-scale buildings.

2. Light weight and strength can meet the needs of use. It is a very good partition with two light gypsum boards.

3. Chemical physical properties are stable, dry moisture absorbing gas, small telescopic deformation

4. Decorative effect. The surface layer of the gypsum board can be compatible with a variety of surface layer decorative materials to meet the decoration requirements for large-scale buildings.

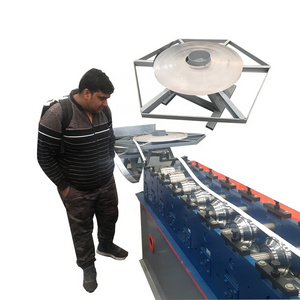

Another Perspective

Parts to introduce

|

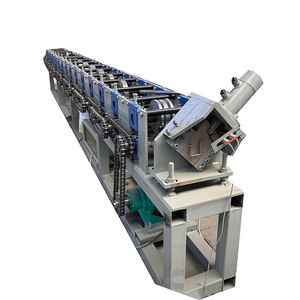

Packing list- C/U roll forming machine

|

|

|

|

|

||||

|

No.

|

Name

|

Unit

|

Quantity

|

Remark

|

||||

|

Part 1

|

3T decoiler

|

set

|

1

|

Manual

|

||||

|

Part 2

|

Main roll forming machine

|

set

|

1

|

High speed

|

||||

|

Part 3

|

PLC control station

|

set

|

1

|

Mitsubishi brand

|

||||

|

Part 4

|

Cutting system

|

set

|

1

|

Hydraulic

|

||||

|

Part 5

|

Hydraulic station

|

Set

|

1

|

45# oil

|

||||

|

Part 6

|

Product table

|

set

|

1

|

Regular

|

||||

Tracking Cut System

PLC Control System

3 Ton Manual De-coiler

|

3 Ton Manual De-coiler

|

|

|

|

Type:

|

passive

|

|

|

Coil width:

|

max 400 mm

|

|

|

Loading capacity:

|

3 tons

|

|

|

Inner diameter:

|

450-550 mm

|

|

Product Advantages

Molding Frame

Not just welding the middle sheets on the Main frame, we use molding frame and fixing by the bolts .Making the rollers are more stable when working and increasing the

Precision.

Straighten Head

In fact when the product has finished, the shape is so good, but we want to make the shape is perfect. We use the straighten head make the channels more straight.

If the speed of working is too high, the worker will be busy for receiving the products. so if you choose a Full Automatic pallety, it would

Reduce

Labor Costs.

Why Choose Us

Advantages of ZTRFM machines:

1.Zhongtuo rollforming equipment can be changed in 20 minutes or less to produce different width and flange heights in different gauges of material.

2.An electro-mechanical adjustment is all that’s required to offer a wide range of stud and track widths on demand. With the Zhongtuo machinery, you can produce studs and tracks in a wide range of material gauges and lip sizes from 3/8” to 5/8” as gauge and standards require.

3.Zhongtuo rollforming equipment can replace outdated rollformers that hold your production with their lengthy changeover times. It can also be matched with your existing pierce and cut-off equipment to minimize cost.

Hot Searches