- Product Details

- {{item.text}}

Quick Details

-

Power:

-

132+3+3+7.5kw

-

Dimension(L*W*H):

-

See Technical Parameters

-

Weight (KG):

-

8000

-

After-sales Service Provided:

-

Video technical support, Online support, Field maintenance and repair

-

Raw material:

-

Straw Grass Wood Branches

-

Name:

-

Tree Root Stump Crusher Machine

-

Application:

-

Wood Processing

-

Usage:

-

Crush Biomass Waste Wood

-

Capacity:

-

2-3t/h

-

Final product:

-

Size Adjustable

-

Package:

-

Wooden Case

-

Color:

-

Customer Required

-

Advantage:

-

High Efficieny

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SANJIN

-

Voltage:

-

380V 50Hz 3Phase

-

Power:

-

132+3+3+7.5kw

-

Dimension(L*W*H):

-

See Technical Parameters

-

Weight (KG):

-

8000

-

After-sales Service Provided:

-

Video technical support, Online support, Field maintenance and repair

-

Raw material:

-

Straw Grass Wood Branches

-

Name:

-

Tree Root Stump Crusher Machine

-

Application:

-

Wood Processing

-

Usage:

-

Crush Biomass Waste Wood

-

Capacity:

-

2-3t/h

-

Final product:

-

Size Adjustable

-

Package:

-

Wooden Case

-

Color:

-

Customer Required

-

Advantage:

-

High Efficieny

Product Description

Tub Stump Grinder Heave Duty Tree Root Stump Crusher Machine

feature:

Equipment characteristics of disc stump crusher:

Introduce:

Disc tree root stump crusher machine is also called the wood comprehensive crusher, rotary wood crusher. This tree root crusher isa large wood crushing equipment, suitable for biomass power generation field, large roots, large diameter logs, templates, boards,branches, straw crushing processing.

Disc tree root stump crusher machine is also called the wood comprehensive crusher, rotary wood crusher. This tree root crusher isa large wood crushing equipment, suitable for biomass power generation field, large roots, large diameter logs, templates, boards,branches, straw crushing processing.

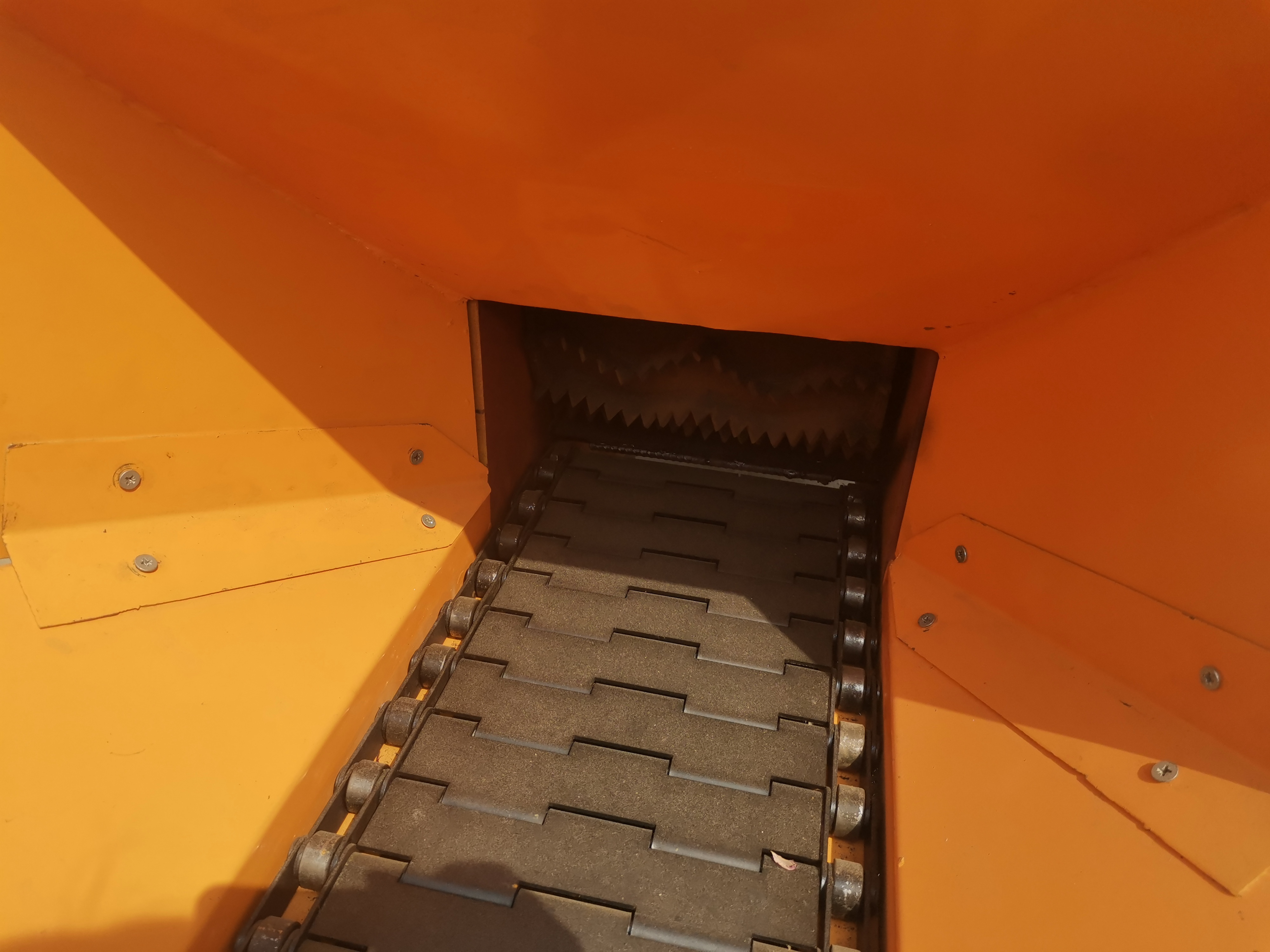

Working principle of disc stump crusher:

When the disc type stump crusher is working, the motor drives the rotor to rotate, and the feed hopper is also driven by the motor to slowly rotate. The material is put into the hopper by the grab machine, and the hopper is rotating at the same time as the inner wall of the material is shifted The teeth will evenly push the material onto the rotor. When the rotating rotor encounters the material, the cutting and tearing of the blade on the rotor realizes the initial crushing of the material. The material that has entered the initial crushing will not fall under the action of its own gravity and the impact of the rotor. On the screen in the crushing chamber, the materials that meet the requirements will be discharged through the screen, and those that do not meet the requirements will be crushed twice or even three times in the crushing chamber until they meet the requirements.

Structure :

Tree stump crusher comprises a frame, a rotary material box which rotates under the drive of a material box driving device, a rotor which rotates under the drive of a rotor driving device, the rotor is positioned below the rotary material box, and the position of a feed inlet and a feed hopper is relatively paranoid. we can using hammer knives (if in the materials have stone or iron )

When the disc type stump crusher is working, the motor drives the rotor to rotate, and the feed hopper is also driven by the motor to slowly rotate. The material is put into the hopper by the grab machine, and the hopper is rotating at the same time as the inner wall of the material is shifted The teeth will evenly push the material onto the rotor. When the rotating rotor encounters the material, the cutting and tearing of the blade on the rotor realizes the initial crushing of the material. The material that has entered the initial crushing will not fall under the action of its own gravity and the impact of the rotor. On the screen in the crushing chamber, the materials that meet the requirements will be discharged through the screen, and those that do not meet the requirements will be crushed twice or even three times in the crushing chamber until they meet the requirements.

Structure :

Tree stump crusher comprises a frame, a rotary material box which rotates under the drive of a material box driving device, a rotor which rotates under the drive of a rotor driving device, the rotor is positioned below the rotary material box, and the position of a feed inlet and a feed hopper is relatively paranoid. we can using hammer knives (if in the materials have stone or iron )

feature:

Equipment characteristics of disc stump crusher:

1. The application of technology, the offset feed inlet combined with the feed tooth installed on the inner wall of the feed hopper plays a role of auxiliary feed, and the equipment adopts frequency conversion technology, once the rotor load is too large, the hopper will be fed Will reverse rotation, so the device does not have to worry about jamming.

2. This equipment can be used for the crushing of large diameter materials such as tree roots and waste furniture, and it can also be used for the crushing of baled straw. It is more suitable for the crushing of small diameter wood and slab scraps. It has the advantage of rapid feeding.

3. Convenient maintenance. The hydraulic material box turning device can realize a large-angle turning when the machine needs maintenance. The rotor part is exposed after turning, which is convenient for maintenance and reduces manual use.

4. The production cost is low. The equipment uses a multi-blade rotor knife roller, which crushes materials more thoroughly and efficiently, and the reasonable arrangement and the use of advanced materials increase the service life of the blade and reduce the production cost.

5. The whole machine has a high degree of automation. This equipment realizes automatic control of all electrical components, and can realize remote wireless control, which reduces manual use and ensures the safety of production.

Specification

|

Model

|

Knife Roll Diameter

|

Fly Blade Quantity

|

Blade Length

|

Hammer Quantity

|

Hammer Quantity

|

Motor Power

|

Knife Roll Speed

|

Feeding Speed

|

|

SJ-700

|

700

|

4PCS

|

480mm

|

28pcs

|

2600mm

|

132+3+3+7.5kw

|

800r/min

|

20m/min

|

Details Images

Raw Materials:

The Final Products:

Related products

Packing & Delivery

Customer Photos

Hot Searches