- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

RH

-

Length:

-

5.7 m,6 m ,etc

-

Application:

-

Water or Sewerage Pipeline Projects etc.

-

Hardness:

-

≤230HB

-

Pipe Wall Thickness:

-

K9, C40, C30, C25, etc

-

Pull Strength:

-

≥420MPa

-

Yield (≥ MPa):

-

≥300Mpa

-

Product Name:

-

Ductile Cast Iron Pipe

-

Joint Type:

-

Push-on Joint (T type) bell and spigot

-

External Coating:

-

zinc +bitumen painting

-

Inner Coating (Lining):

-

cement mortar lining

-

advantage:

-

Large inventory, fast delivery

-

Gasket Material:

-

EPDM

-

Test:

-

third party testing

-

Packing:

-

Standard Seaworthy Packing

-

Payment terms:

-

TT LC etc

-

specifications:

-

DN80-DN2600

Quick Details

-

Standard:

-

ISO2531/EN545/EN598

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Runhai Ductile Iron Pipe tube

-

Model Number:

-

RH

-

Length:

-

5.7 m,6 m ,etc

-

Application:

-

Water or Sewerage Pipeline Projects etc.

-

Hardness:

-

≤230HB

-

Pipe Wall Thickness:

-

K9, C40, C30, C25, etc

-

Pull Strength:

-

≥420MPa

-

Yield (≥ MPa):

-

≥300Mpa

-

Product Name:

-

Ductile Cast Iron Pipe

-

Joint Type:

-

Push-on Joint (T type) bell and spigot

-

External Coating:

-

zinc +bitumen painting

-

Inner Coating (Lining):

-

cement mortar lining

-

advantage:

-

Large inventory, fast delivery

-

Gasket Material:

-

EPDM

-

Test:

-

third party testing

-

Packing:

-

Standard Seaworthy Packing

-

Payment terms:

-

TT LC etc

-

specifications:

-

DN80-DN2600

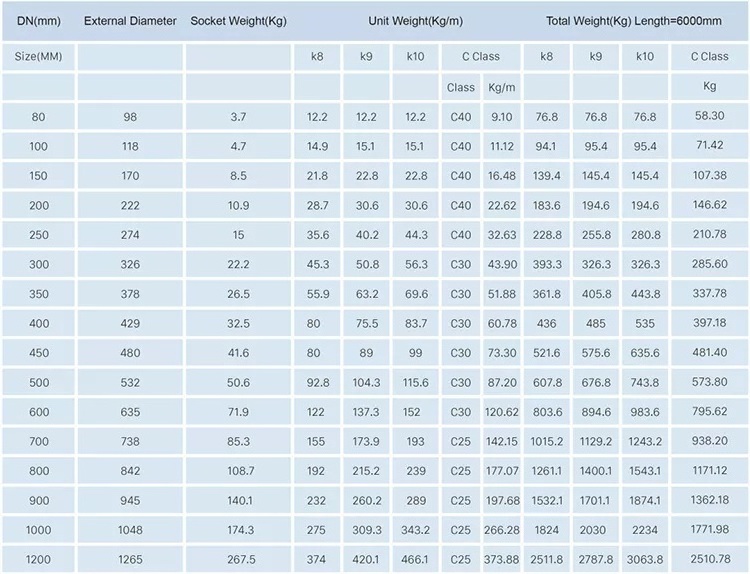

Product Parameter

|

All specifications products can be customized according to customer requirements

|

|

|

|

Product Name

|

Ductile iron pipe

|

|

|

|

Outside Diameter: 98mm-1255mm

Inside Diameter: 80mm-1200mm Wall Thickness: 6mm-153mm Length: 6m, cut to 5.7m, or as required. |

|

|

Grade

|

K9, K10, K11, K12,K9, K8, C25, C30, C40, etc.

|

|

|

Standard

|

ISO2531, EN545, EN598, etc

|

|

|

Surface

|

External bitumen coating, or as required.

|

|

|

|

a). Portland cement mortar lining

b). Sulphate Resistant cement mortar lining

c). High-Aluminum cement mortar lining

d). Fusion bonded epoxy coating

e). Liquid epoxy painting

f). Black bitumen painting

|

|

|

|

a). zinc+bitumen(70microns) painting

b). Fusion bonded epoxy coating

c). Zinc-aluminum alloy +liquid epoxy painting

|

|

|

Quality Control

|

100% inspection + professional Lab test

|

|

|

Certification

|

ISO, CE, BSI, WRAS,SGS,etc

|

|

|

Package

|

Standard export package, or as required.

|

|

|

Payment

|

T/T, L/C, Western Union, etc.

|

|

|

Application

|

Water supply project, drainage, sewage, irrigation, water pipeline, etc.

|

|

Centrifugal casting nodular cast iron pipe is a pipe made of nodular cast iron by centrifugal spinning process. The pipeline cantransport fluid media such as water, oil and gas, and is widely used in various pipeline projects such as metallurgy,mining,water conservancy, petroleum, urban public services and so on. Ductile iron pipe has the advantages of high strength,good toughness, better than steel and good corrosion resistance. It is an ideal substitute for gray cast iron pipe and ordinary steel pipe. In addition, the produced Di pipe has good flatness, uniform wall thickness, high dimensional accuracy, good surface finish, excellent mechanical properties and firm adhesion of internal and external coatings.Flexible quick connectors and rubber gaskets are used to facilitate pipe installation. By combining the amazing ductility, high tensile strength and good corrosion resistance of nodular cast iron, this easy to operate pipe can be easily tapped, drilled or welded. Nodular cast iron pipe is famous for its practical performance, which provides unparalleled advantages for the application of water,sewage and natural gas mains!

Product Show

Ductile iron pipe

Ductile iron pipes are available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron pipes are simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

Product details

1.The performance of internal pressure resistance:

Centrifugal ductile iron has the essence of iron and the performance of steel, so the ductile iron pipes have excellent security performance than pipes made from other materials. The designed working pressure is much higher than that of pipes made from other materials, the safty factor is pretty high, and the possible burst pressure is three times of the working pressure.

2.The performance of outer pressure resistance:

The high pressure resistance can avoid the requirement of the pipe bed and protective cover, making the pipes laying rellable and economic.

3.Inner anti-corrosion layer:

The inner layer of ductile iron pipes are centrifugally sprayed with cement mortar. Cement lining complies with the international standard ISO4179, ensuring the mortar strong and smooth. The motor coating will not fall off or foul, and its thickness is even ensuring the drinking water transferred by the pipes get good protection.

4.Protective coating:

The zinc spraying of ductile iron pipes could protect the pipes proactively through the electrochemical effect of zinc and iron. With the high chiorinated resin paint, the pipes will get enhanced anti-corrosion protection. The surface zinc spraying of each pipe is not less than 130g/m², amd cpmplies with ISO8179 standard. We can also increase the zinc spraying thickness or spray zinc & aluminum alloy layer according to the customers' demand.

Inspection

Strict quality control, can accept the third party testing.

Hot Searches