- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Material:

-

Plastic/Stainless, SUS304

-

Dimension(L*W*H):

-

8000*1800*2200mm

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

1500 kg

-

Product Name:

-

crate washing machine

-

Keywords:

-

High Efficiency

-

Heating Method:

-

Electricity/ Steam

-

Speed:

-

Adjustable

-

Voltage:

-

380V/ Customized

-

Pump type:

-

A Brand

-

Type:

-

High Pressure Washer

-

Capacity:

-

300-1000pcs/h

-

Application:

-

Washing and Drying Industry

Quick Details

-

Cleaning Process:

-

Hot Water Cleaning

-

Power:

-

40kw

-

Max. Pressure:

-

10Mpa

-

Place of Origin:

-

Shandong, China

-

Material:

-

Plastic/Stainless, SUS304

-

Dimension(L*W*H):

-

8000*1800*2200mm

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

1500 kg

-

Product Name:

-

crate washing machine

-

Keywords:

-

High Efficiency

-

Heating Method:

-

Electricity/ Steam

-

Speed:

-

Adjustable

-

Voltage:

-

380V/ Customized

-

Pump type:

-

A Brand

-

Type:

-

High Pressure Washer

-

Capacity:

-

300-1000pcs/h

-

Application:

-

Washing and Drying Industry

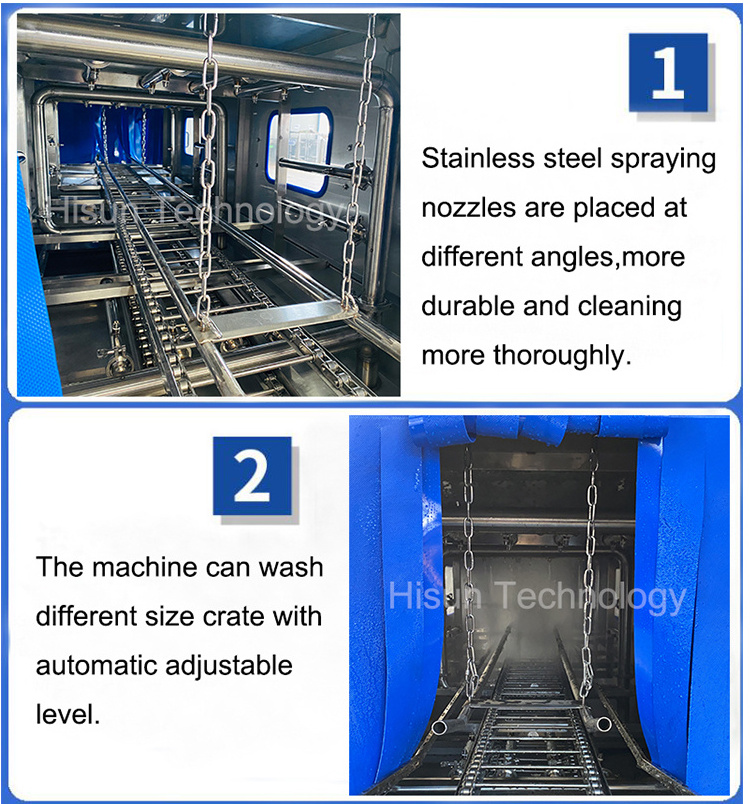

Products Description

Working Principle

Using high temperature (>80℃) and high pressure (0.2-0.7Mpa), the container is washed and sterilized in four steps, and then the high-efficiency air-drying system is used to quickly remove the surface moisture of the container and reduce the turnover time. It is divided into spray pre-washing, high-pressure washing, spray rinsing, and spray cleaning; the first step is to pre-wash containers that are not in direct contact with ingredients such as external turnover baskets by means of high-flow spray, which is equivalent to soaking the containers. , which is helpful for subsequent cleaning; the second step uses high-pressure washing to separate the surface oil, dirt and other stains from the container; the third step uses relatively clean circulating water to further rinse the container. The fourth step is to use uncirculated clean water to rinse the residual sewage on the surface of the container, and to cool the container after high temperature cleaning.

Product Details

Easy to clean

The protection level of the container sterilization cleaning machine is as high as IP69K, which can directly carry out sterilization washing, chemical cleaning, steam sterilization, and thorough sterilization. Supports quick disassembly and washing, leaving no dead corners for cleaning and avoiding the risk of bacterial growth.

Safe bacteria control

The overall material of the container sterilization cleaning machine adopts stainless steel 304, pharmaceutical grade seamless welding technology, the pipeline connection is smooth and seamless, there is no hygienic dead angle after cleaning, to avoid bacterial growth, the protection level reaches IP69K, and the sterilization and cleaning are convenient.

Product Display

The advantages of industrial washer:

Clip-on nozzles, easy to adjust and easy to clean.

Energy-efficient pivot system ensures efficient cleaning of pallets and dividers.

A-brand spare parts, available worldwide.

Hygienic design.

Low maintenance costs.

Compact machine.

Easy to use.

Low infeed and outfeed height.

Fully customizable to your wishes and requirements, also customer-specific.

Long lifespan.

Energy-efficient pivot system ensures efficient cleaning of pallets and dividers.

A-brand spare parts, available worldwide.

Hygienic design.

Low maintenance costs.

Compact machine.

Easy to use.

Low infeed and outfeed height.

Fully customizable to your wishes and requirements, also customer-specific.

Long lifespan.

High efficiency with good quality

High cleaning efficiency and good effect. Four-step cleaning method under high temperature and high pressure, 360°cleaning without dead angle, cleaning speed can be adjusted according to production needs, nozzle angle can

be adjusted, and the lower nozzle can be swung.

be adjusted, and the lower nozzle can be swung.

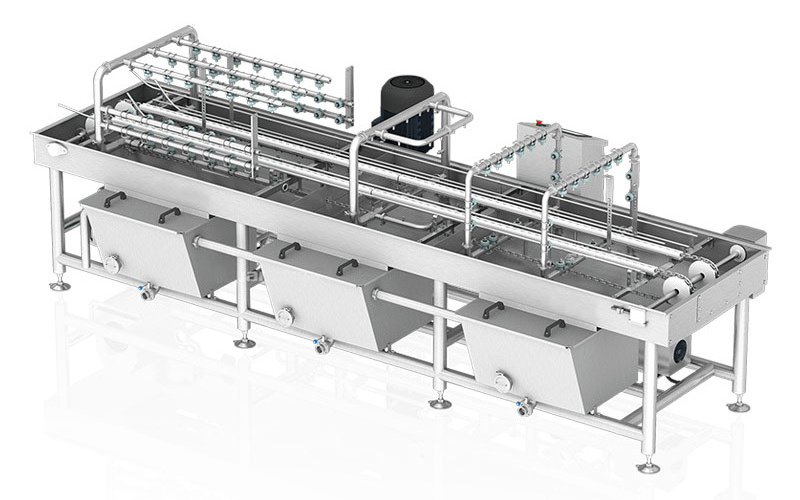

3D View

Product Application

Widely used in baking tins, baking trays, bins, cheese moulds, containers, cutting plates, eurobins,

medical containers, pallet dividers, parts, shopping carts, wheel chairs,baking tins couples,barrels, bread crates, chocolate

moulds, crates, egg trays, meat gloves, pallet boxes, pallet, shopping baskets, trolleys, reset etc.

medical containers, pallet dividers, parts, shopping carts, wheel chairs,baking tins couples,barrels, bread crates, chocolate

moulds, crates, egg trays, meat gloves, pallet boxes, pallet, shopping baskets, trolleys, reset etc.

Product packaging

Customer Cases

Hot Searches