- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1.5-3mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v/3phase/50hz or customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

kg

-

Feeding width:

-

customized

-

Product name:

-

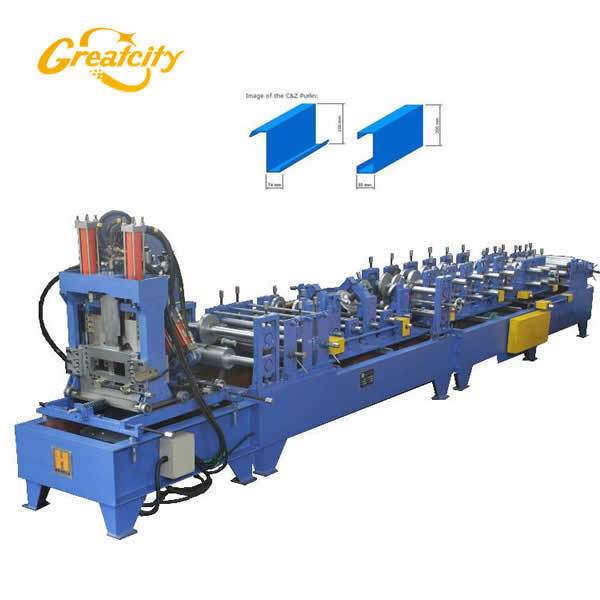

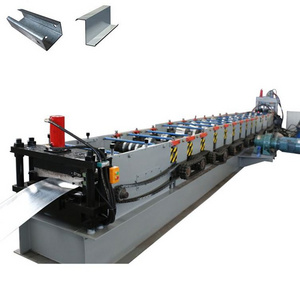

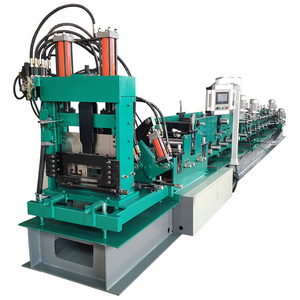

z & c roll forming machine production line.

-

Roller material:

-

GCr15

-

Usage:

-

Making cz keel

-

Shaft material:

-

45# Steel Outer Diameter: 80mm

-

Thickness:

-

0.3--3mm

-

Control system:

-

Delta

-

Color:

-

Blue

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Cutting blade material:

-

Cr 15 High Grade Steel

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-15m/min or customized

-

Rolling thinckness:

-

1.5-3mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v/3phase/50hz or customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

kg

-

Feeding width:

-

customized

-

Product name:

-

z & c roll forming machine production line.

-

Roller material:

-

GCr15

-

Usage:

-

Making cz keel

-

Shaft material:

-

45# Steel Outer Diameter: 80mm

-

Thickness:

-

0.3--3mm

-

Control system:

-

Delta

-

Color:

-

Blue

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Cutting blade material:

-

Cr 15 High Grade Steel

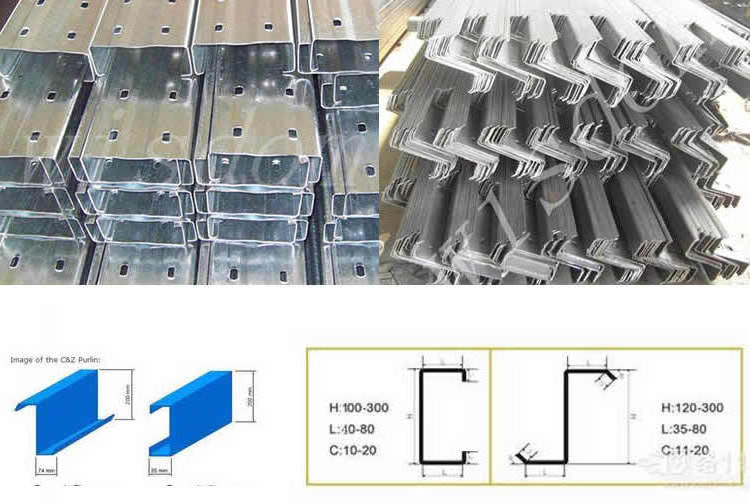

Precise profiles Fully automatic z & c roll forming machine/c channel roll forming machine production line

z & c roll forming machine has now become an indispensable equipment for construction of I-beam and channel steel in tunnels, subway, hydropower stations, underground caverns, etc

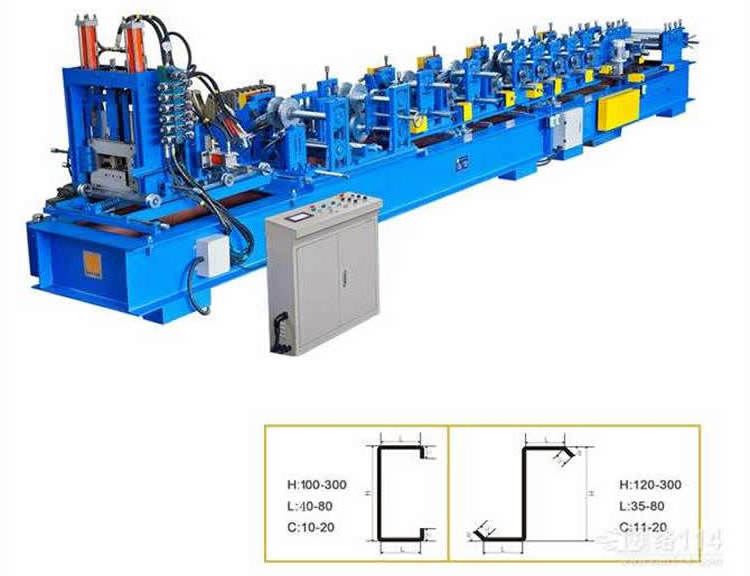

c z purlin roll forming machine features:

1.Upgraded version of CZ integrator, fast transformation; 1-2 minutes transformation of 2.specifications and CZ

3.Realization of Automatic Conversion of CZ Specification

4.Realize CZ automatic flip 180 degrees

z & c roll forming machine

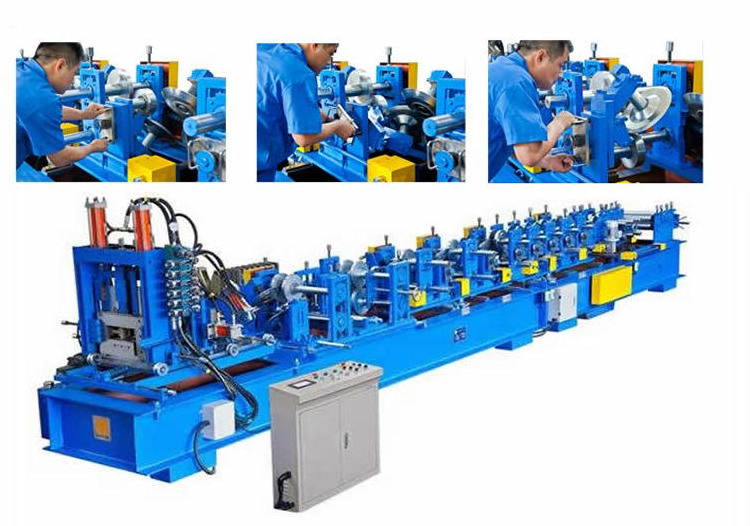

1. Spindle material: 45# steel quenching and tempering treatment, outer diameter Φ80mm

2, roll material:

1) Cr12 chrome steel quenching treatment HRC60-62 ° (optional)

2) GCR15 bearing steel quenching treatment HRC58-60°

3, the number of leveling rolls: 5 roll leveling

4, the number of main rolls: 15 rows (3 rows of leveling 12 rows of molding)

5, the main motor power: 11KW

6, rolling speed: 8-12 m / min

7. Cutting system: It adopts advanced hydraulic drive and automatically cuts the length after forming. Invariable, no waste, high safety factor. (The host stops cutting)

8. Punching: hole type drawing, can be adjusted freely before and after any setting

9, blade, punch material: Cr12, quenching treatment 60-62 °

10, electronic control system: the whole machine uses PLC, inverter control, rotation straightening

11, the size of the host: about 10.5M × 1.7M wide × 1.2M high

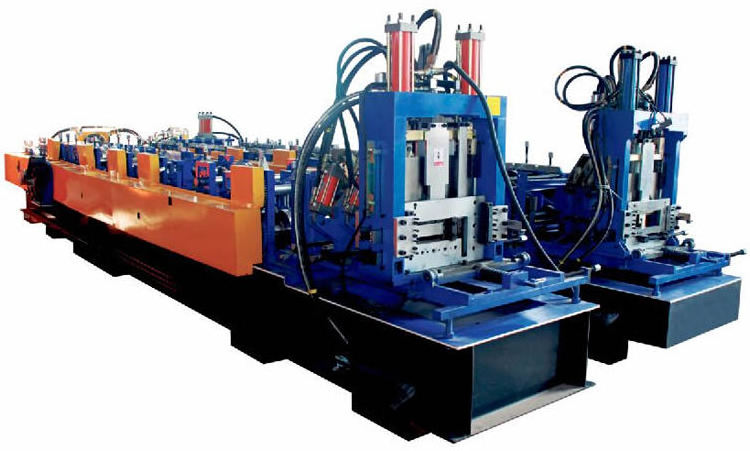

z & c roll forming machine charging:

1) Manual discharge rack, inner tension type, loading inner diameter 450mm--600mm, width ≤600mm, maximum loading weight 4000KG

2) Automatic inner tensioning and discharging rack width ≤600mm, Width <= 600mm, maximum loading weight: 7000KG

Hydraulic power: 3KW

Cylinder diameter: 120mm, working pressure: 10Mpa

z & c roll forming machine detailed show :

packaging information: standard export seaworthy packing by sea

. We have our own farwarder. We can check the delivery information timely. You can also use forwarder by yours. We will contact with him ASAP.

Delivery time: about 12-15 days after receiving the deposit for z & c roll forming machine