- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Pump

-

Place of Origin:

-

Henan, China

-

Structure:

-

Centrifugal pump

-

Power:

-

Max200kw

-

Microscope Theory:

-

Slurry Pump

-

Standard or Nonstandard:

-

Standard

-

Fuel:

-

Diesel

-

Pressure:

-

High Pressure

-

Material:

-

Cast Iron

-

Product name:

-

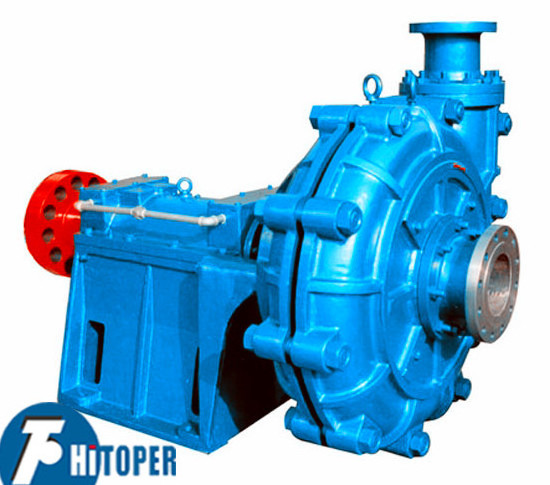

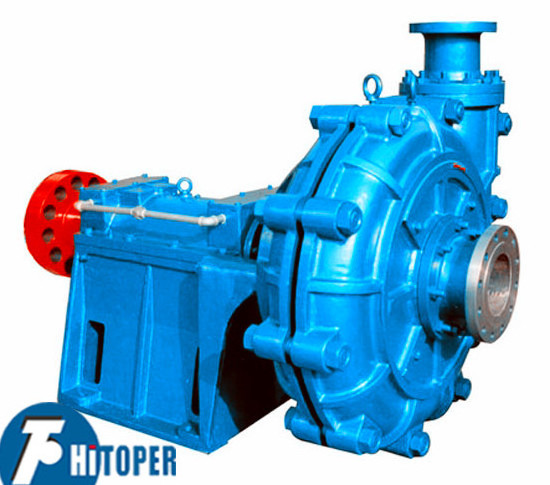

Filter press feed pump, slurry pump

-

Type:

-

Watering

-

Feature:

-

High Efficiency

-

Usage:

-

Wastewater treatment

Quick Details

-

Application:

-

Other, Automotive Industry, Drinking water treatment, Food and Beverage Industry, Irrigation and Agriculture, Machining, Marine, Mining industry, Pharmaceutical industry, Washing and Cleaning, wastewater treatment, Water Distribution, Water Treatment Solutions, Mining, Metallurgy, Petroleum, Chemical, Environmental protection, Electroplating, Food, Pharmacy, Oil, Biological, Beverage, Brewing, Textiles, Printing, Dyeing, Papermaking, Inorganic salt, Coal washing, Sewage treatment, Ceramics, Leather, Blood product, Wastewater treatment, Light industry

-

Warranty:

-

1 year

-

Brand Name:

-

Toper

-

Model Number:

-

Pump

-

Place of Origin:

-

Henan, China

-

Structure:

-

Centrifugal pump

-

Power:

-

Max200kw

-

Microscope Theory:

-

Slurry Pump

-

Standard or Nonstandard:

-

Standard

-

Fuel:

-

Diesel

-

Pressure:

-

High Pressure

-

Material:

-

Cast Iron

-

Product name:

-

Filter press feed pump, slurry pump

-

Type:

-

Watering

-

Feature:

-

High Efficiency

-

Usage:

-

Wastewater treatment

Filter press feed pump, slurry pump

Application:

1.Wastewater lift station;

2.Municipal wastewater treatment plant;

3.Building wastewater treatment system; Animal & poultry farm wastewater treatment system;

4.Hospital, school, community etc. Wastewater treatment system; Food, paper, mining, textile, leather, chemical industry etc. wastewater treatment system.

5.Water purification system.

Features:

MOTOR

Squirrel cage, induction motors F class insulation. motor protection grade IP68.

NON-CLOG IMPELLER

Well statically & dynamically balanced Non-Clog impeller is designed to allow sizable spherical solids to pass the plow passage easily without clogging.

It adopts rigorous

technics to reduce vibration and noise.

SEAL MECHANISM

The cable assembly is formed to one piece.The mechanical seals protect the motor from contacting the liquids.Two ways of the sealing

work separately for motor protection.

AUTO-SETTER

To allow pump for easy installation, maintenance & reparation, no need to empty the tank first.

LEAKAGE DETECTOR

Built-in leakage detector in the oil chamber can dectet leakage from the damage of the mechanical seal. (power lower can be 15Kw lower) Leakage detector in wire box can check for leakage and provide automatic protection. (Without stamdard accessories, power can be 18.5Kw lower)

HEAT-DETECTOR

Heat protector in the motor, secures the protection of motor against burning out. (power can be 15Kw lower) overload & overheating to heat protector in bearing, temp

erature rises to disconneting temperature when is not normal, protector automatically cutsoff power.

COOLING HOUSE (OPTINS)

Pumps make use of inner pressure of pump cauvty to make liquid continue entering the space between cooling house and motor outer, to take away produced heat.

Detailed description:

1. Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump

2.High head, large capacity, high efficiency.

3.Good NPSH performance.

4.Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

5.Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy).

6.The frame plate for pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber.

7.Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

8.Centrifugal seal, mechanical seal and packing seal are available.

9.The shaft seals for type M AH and HH pumps may be adoptable of gland seal or expeller seal

10.The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.

1.On-line technician for consultation.

2.Schedule factory visit.

3.Overseas engineers for installation,training,problem-solving.

About Toper

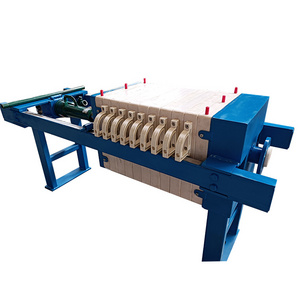

Zhengzhou Toper is the leading suppiler of industrial equipment in China,and also the professional exporter and service provider of filter and separation equipment.

We focus on full service for filtering project from design to after-sales service and fast supply of spare parts.

Capability:

The leading supplier of industrial equipment in China.

The professional exporter and service provider of filter and separation equipment.

Our company supplies various types of filter press,centrifuge and relevant parts.

All products of Toper:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compress filter press

4. Mechanical compress filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Round plate filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY rotary drum thickning/dehydrating belt filter press

14. Triple-belt thickning and dehydrating filter press

15. SS type three-foot upper discharge centrifuge

16. SD type three-foot and filter bag hoist discharge centrifuge

17. PD type filter bag hoist discharge centrifuge

18. Centrifuge of up discharge, three foot, clean series SSB, SB

19. SX type manual top discharge centrifuge

20. PS type manual top discharge centrifuge

21. SGZ type automatic scraper bottom discharge centrifuge

22. PGZ type scarper bottom discharge centrifuge

23. LW series decanter centrifuge

2 4. Tubular centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomite filter

28. Filter late

29. Filter cloth

30. Vacuum disc filter

Q1: How long is the Warranty of the machine?

A1: 12 months.

Q2: How can I get more discount?

A2: In general, our MOQ is 1set with reasonable price, with larger order, we can apply to get you an appropriate discount.

Q3: When can I get the quotation?

A3: Please note us the solid content,processing teperature,PH range and daily processing amount, we will get back to you ASAP.

Q4: How long does it take to receive my products?

A4: Generally, within 45 days.