- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PVDF

-

Tensile Strength:

-

25MPA

-

Product name:

-

Hot Selling high flame-resistant pvdf heat shrink tube

-

Operating Temperature:

-

-55°C - 175°C

-

Shrink Temperature:

-

155~ 175°C

-

Shrink ratio:

-

2:1

-

Size:

-

Size

-

Characteristics:

-

Wear & heat resistant, oil & chemical solvent resistant

-

Usage:

-

Electronic, automotive and military applications

-

Flammability rating:

-

VW-1

-

Certification:

-

RoHS Compliant

-

Keywords:

-

pvdf heat shrink tube

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SUNBOW

-

Model Number:

-

SBD-PVDF-HST

-

Material:

-

PVDF

-

Tensile Strength:

-

25MPA

-

Product name:

-

Hot Selling high flame-resistant pvdf heat shrink tube

-

Operating Temperature:

-

-55°C - 175°C

-

Shrink Temperature:

-

155~ 175°C

-

Shrink ratio:

-

2:1

-

Size:

-

Size

-

Characteristics:

-

Wear & heat resistant, oil & chemical solvent resistant

-

Usage:

-

Electronic, automotive and military applications

-

Flammability rating:

-

VW-1

-

Certification:

-

RoHS Compliant

-

Keywords:

-

pvdf heat shrink tube

Product Description

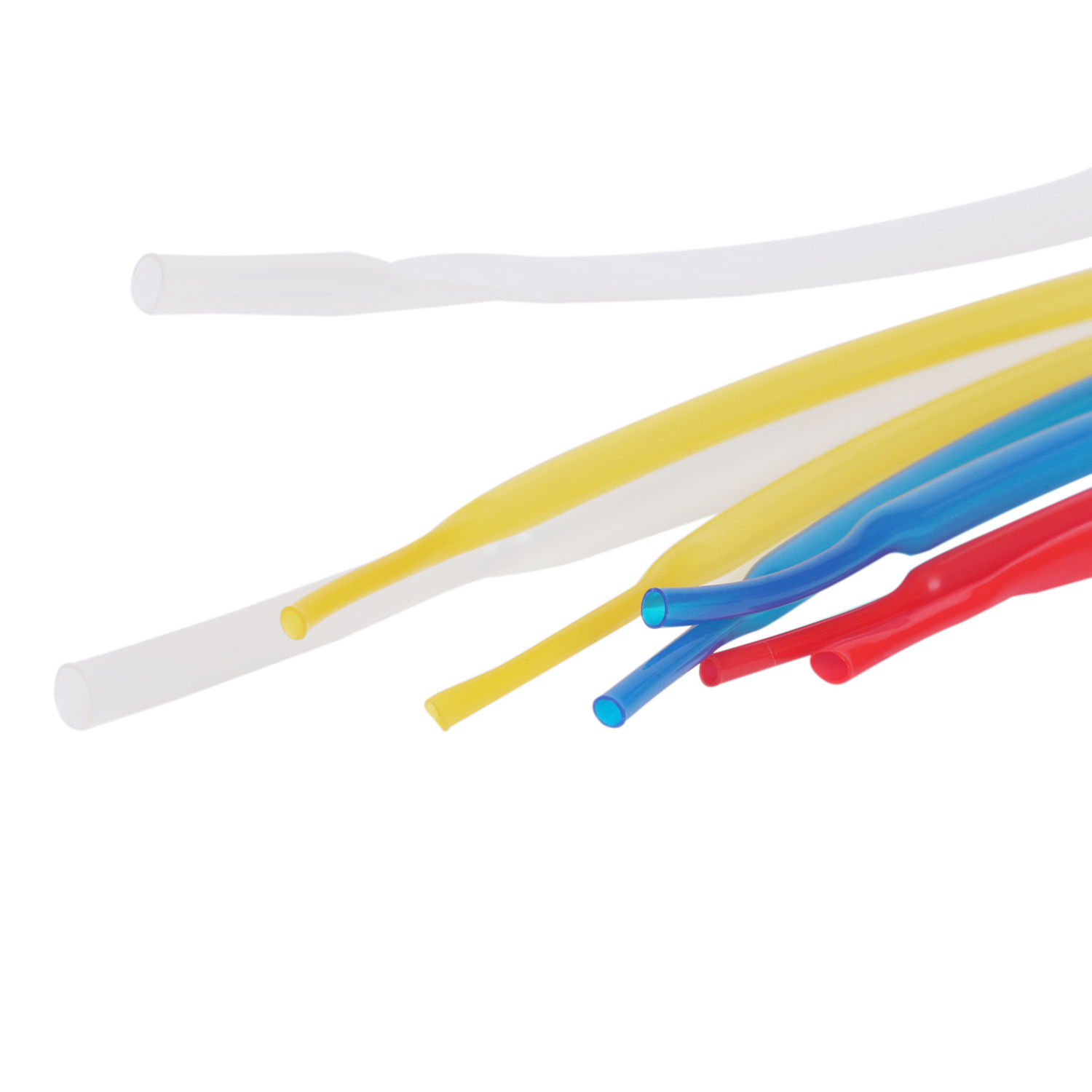

2:1 Good Quality Insulation Tube PVDF Thermoplastic Polymer Heat Shrink Tubing

Model Number: SBD-PVDF-HST

Working temperature:

-55°C ~ 175°C

Usage

Semi-rigid thin wall PVDF heat shrink tubing, ideal for electronic, automotive and military applications requiring

protection and see-through inspection. It can be widely used in high temperature, industrial fuels, solvents and

chemical erosion of weld, terminal and the connection to protect the cables

protection and see-through inspection. It can be widely used in high temperature, industrial fuels, solvents and

chemical erosion of weld, terminal and the connection to protect the cables

Characteristics

1. High withstand to abrasion and cut-through

2. Excellent chemical and solvent resistance

3. Shrink Temperature: 175°C

4. Shrink ratio: 2:1

2. Excellent chemical and solvent resistance

3. Shrink Temperature: 175°C

4. Shrink ratio: 2:1

|

Item

|

Test Method

|

Unit

|

Specifications

|

|

|

Min Shrink Temperature

|

-

|

°C

|

155

|

|

|

Operation Temperature

|

-

|

°C

|

-55 ~ 175

|

|

|

Specific Gravity

|

ASTM D792

|

g/cm3

|

1.78

|

|

|

Tensile Strength

|

ASTM D2671

|

M Pa

|

≥25

|

|

|

Elongation at Break

|

ASTM D2671

|

%

|

≥550

|

|

|

After Aging Elongation

|

250°C,168hrs

|

%

|

≥500

|

|

|

Heat Shock

|

300°C, 4hrs

|

-

|

No Cracking

|

|

|

Cold Bend

|

-55°C, 4hrs

|

-

|

No Cracking

|

|

|

Volume Resistivity

|

ASTM D257

|

Ω. cm

|

≥1013

|

|

|

Flammability Rating

|

UL-224

|

VW-1

|

Pass

|

|

|

Size

|

|

As Supplied (mm)

|

After Recovery (mm)

|

|

Standard Package

|

||

|

(inch)

|

(mm)

|

Internal Diameter (mm)

|

Internal Diameter (mm)

|

Wall Thickness (mm)

|

(m/spool)

|

||

|

3/64

|

1.2

|

1.2

|

0.6

|

0.25±0.05

|

200

|

||

|

1/16

|

1.6

|

1.6

|

0.8

|

0.25±0.05

|

200

|

||

|

3/32

|

2.4

|

2.4

|

1.2

|

0.25±0.05

|

200

|

||

|

1/8

|

3.2

|

3.2

|

1.6

|

0.25±0.05

|

100

|

||

|

3/16

|

4.8

|

4.8

|

2.4

|

0.25±0.05

|

100

|

||

|

1/4

|

6.4

|

6.4

|

3.2

|

0.30±0.05

|

100

|

||

|

3/8

|

9.5

|

9.5

|

4.8

|

0.30±0.05

|

50

|

||

|

1/2

|

12.7

|

12.7

|

6.4

|

0.30±0.05

|

50

|

||

|

3/4

|

19.1

|

19.1

|

9.5

|

0.36±0.05

|

50

|

||

|

1

|

25.4

|

25.4

|

12.7

|

0.41±0.05

|

50

|

||

|

1-1/2

|

38.1

|

38.1

|

19.1

|

0.50±0.05

|

50

|

||

2:1 Good Quality Insulation Tube PVDF Thermoplastic Polymer Heat Shrink Tubing

Related Products

Certificate

Packing&Shipping

2:1 Good Quality Insulation Tube PVDF Thermoplastic Polymer Heat Shrink Tubing

Company Introduction

Shenzhen Sunbow Insulation Materials MFG CO., LTD. is ISO9001:2008 approval insulation sleeving manufacturer.

It is locatedinShenzhen, China. Our main products include: Fiberglass sleevings (with/without coating)

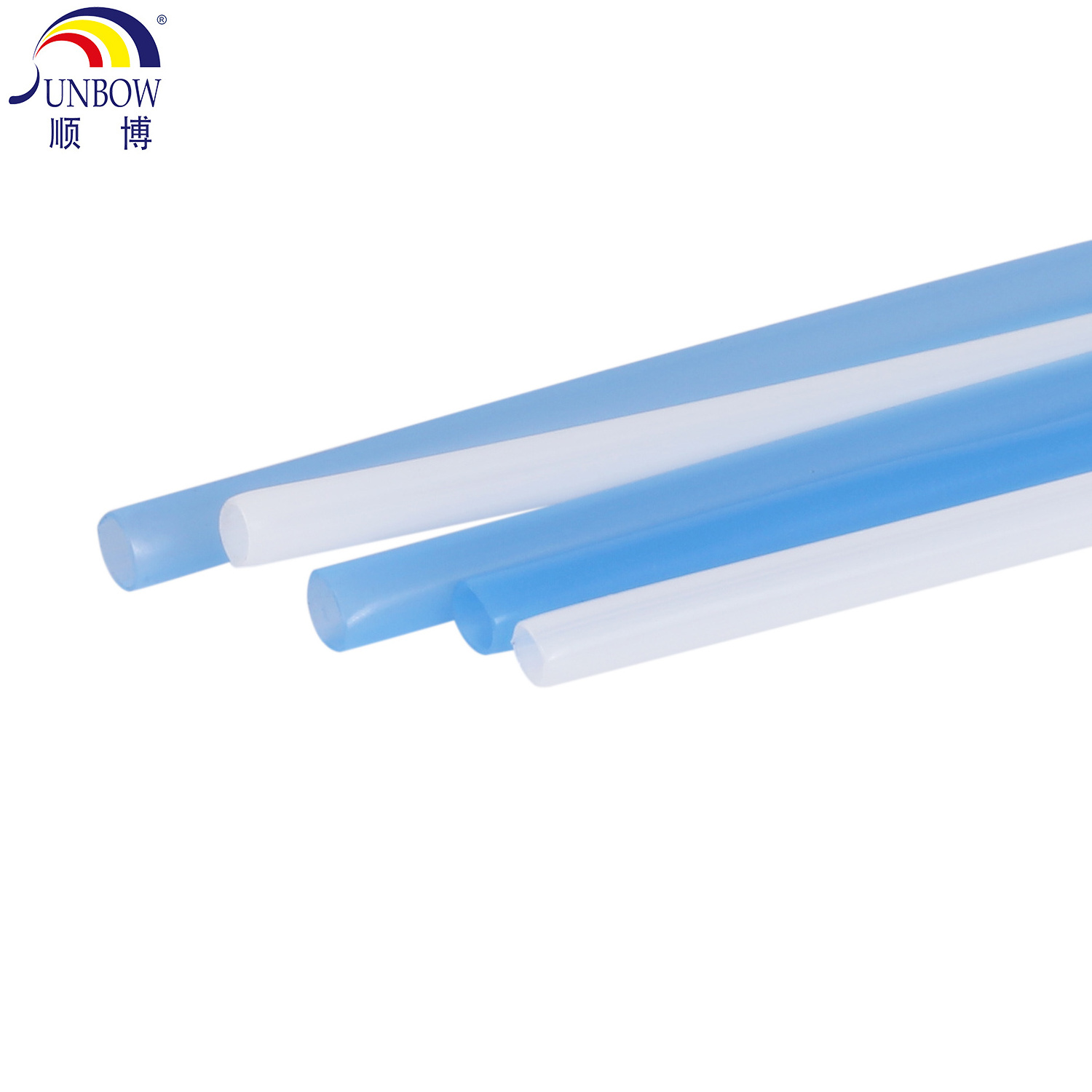

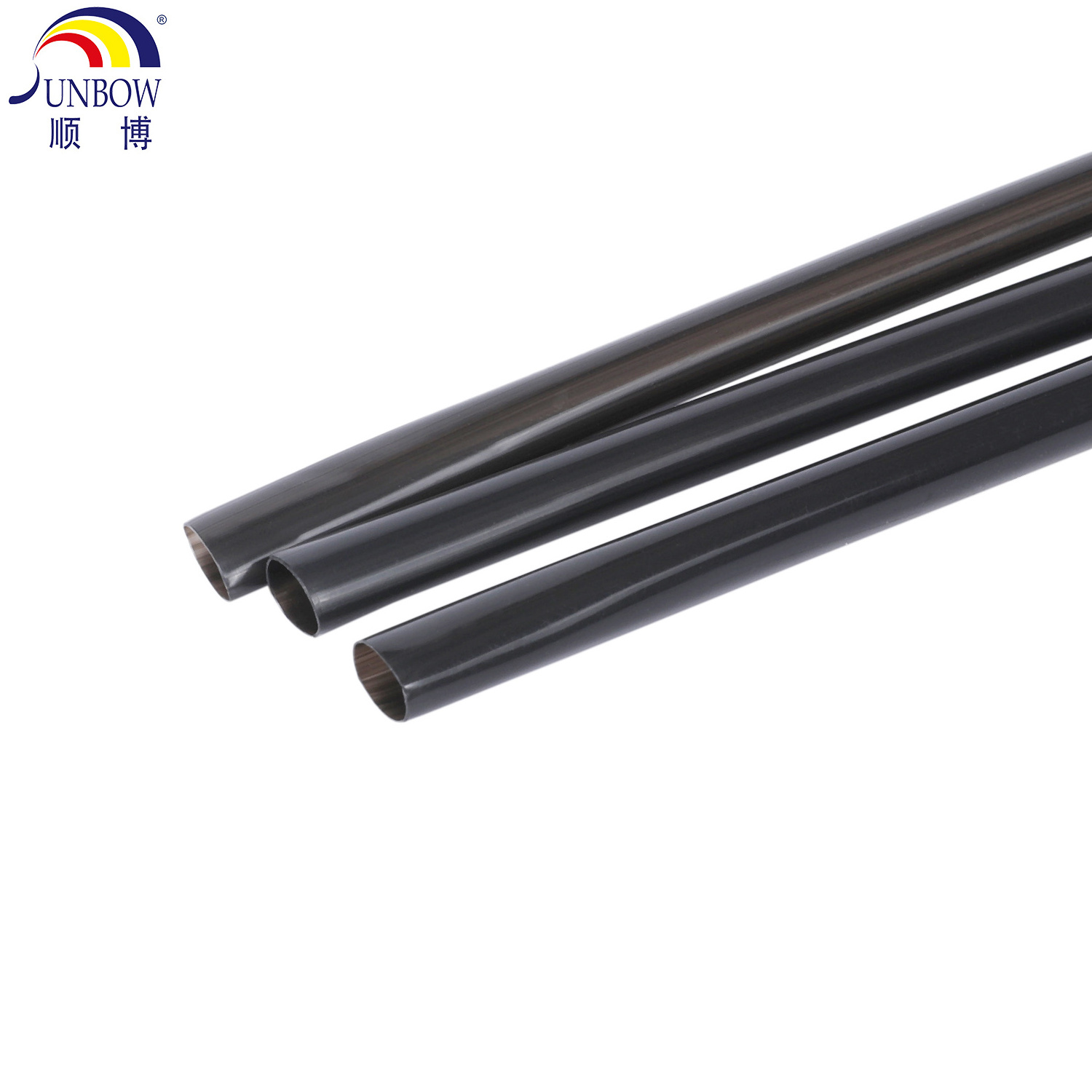

Heat shrink tubes. (PE, Silicone, PTFE,PVC material / shrink ratio 2:1, 3:1,4:1)

Silicone tubes / PTFE tubes / PVC tubes

Expandable braided sleevings (PET, PA6,PA66,PPS)

Nomex tubing, Polyimide film tubing, PET tubing (Mylar tubing) / Insulation Wire.

Heat shrink tubes. (PE, Silicone, PTFE,PVC material / shrink ratio 2:1, 3:1,4:1)

Silicone tubes / PTFE tubes / PVC tubes

Expandable braided sleevings (PET, PA6,PA66,PPS)

Nomex tubing, Polyimide film tubing, PET tubing (Mylar tubing) / Insulation Wire.

Our Services & Strength

1).Free samples for evaluation

2).Quick production&fast delivery

3).2 years quality guarantee

4).Prompt response&technical support

5).24 hours online service

5).24 hours online service

Cooprative Partner

FAQ

Q1. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q2. How about your delivery time?

A: Generally, it will take 20 to60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3.Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds andfixtures.

Q4. What is your sample policy?

Q4. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the

sample cost and the courier cost.

sample cost and the courier cost.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q6:How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure ourcustomers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches